Pre-crack blasting hole charging device for foundation pit excavation

A technology of pre-split blasting and blasting charge, applied in blasting and other directions, can solve the problems of difficult to precisely control the installation position, affecting the effect of pre-split blasting, etc., to prevent brewing accidents, overcome the randomness of installation, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1. Pre-splitting blasting blasthole charging system and device

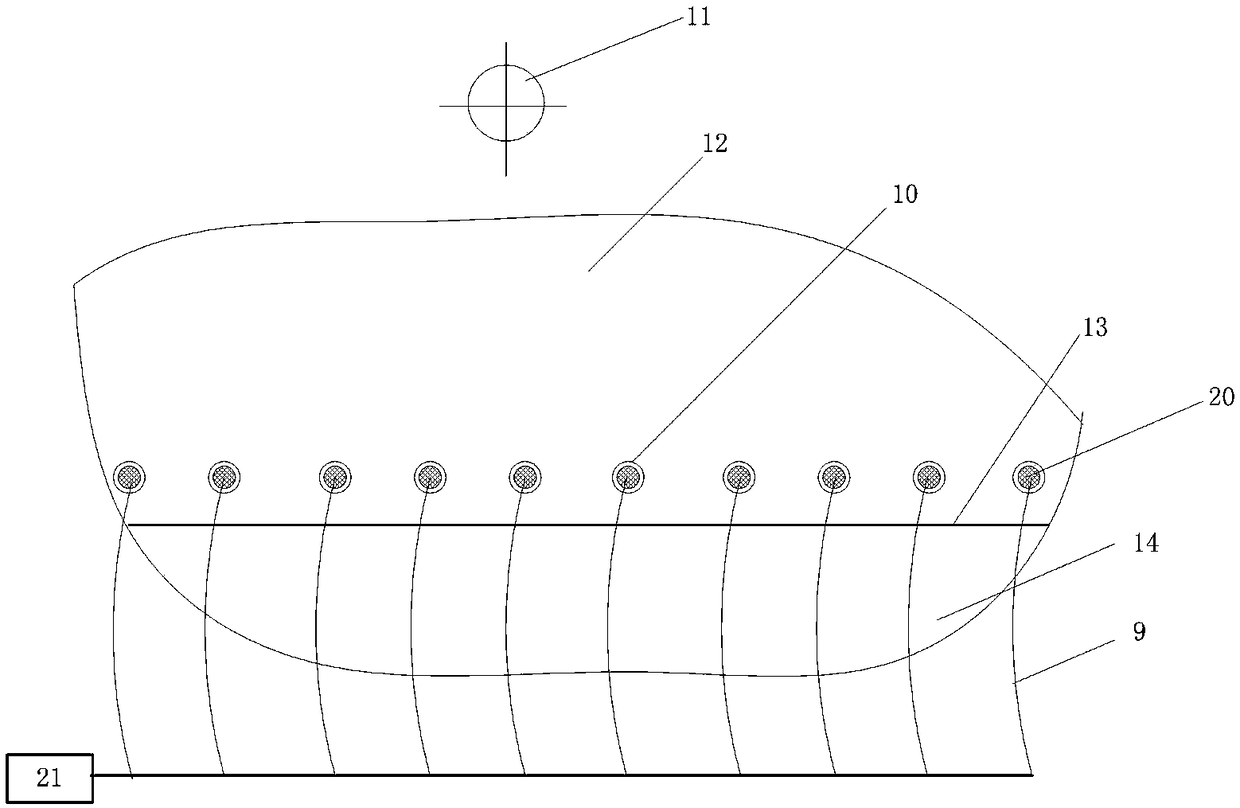

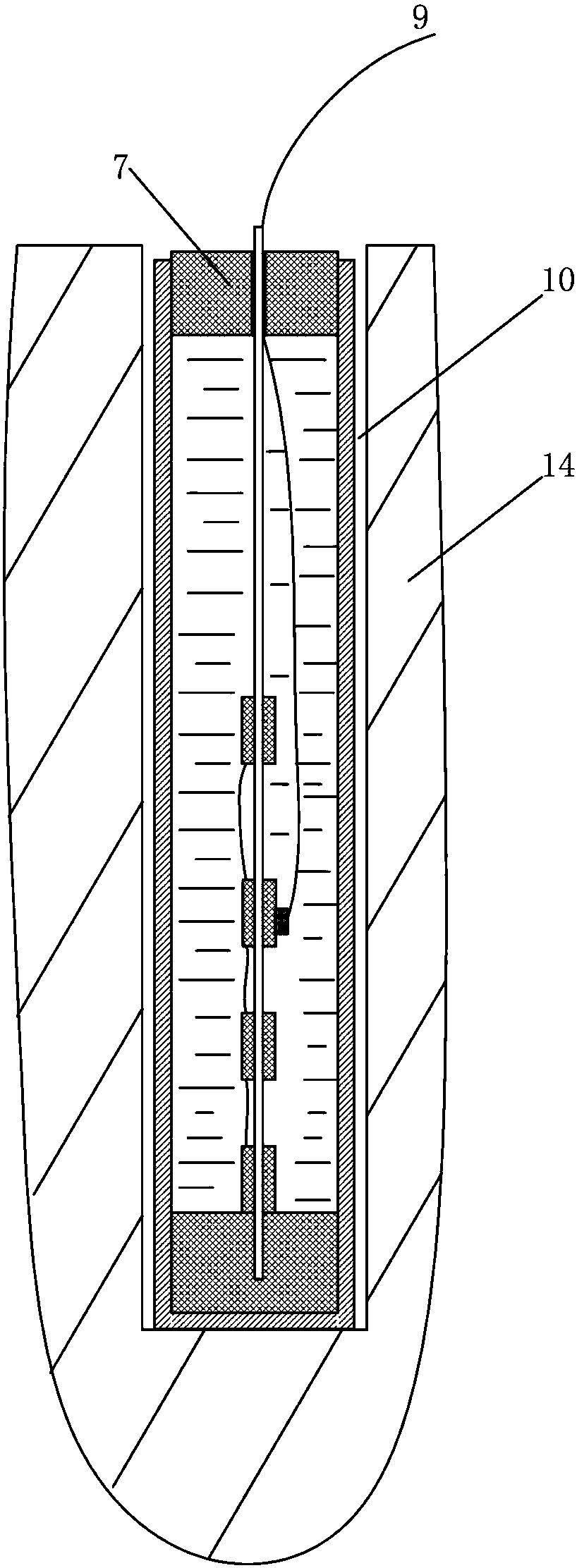

[0025] like figure 1 As shown, the pre-splitting blasting is to drill a row of blastholes 10 on the blasting rock 14, the charge device 20 is arranged inside the blasthole 10, and the uncoupled charge method is adopted, and the front blaster 21 is blasted in the main blast zone 12 where the blast center 11 is located. The internal electronic detonator is detonated, and the row of charge devices is detonated, so that the rock 14 is pulled off at the excavation surface, forming a contour line 13 that runs through the fissure neatly.

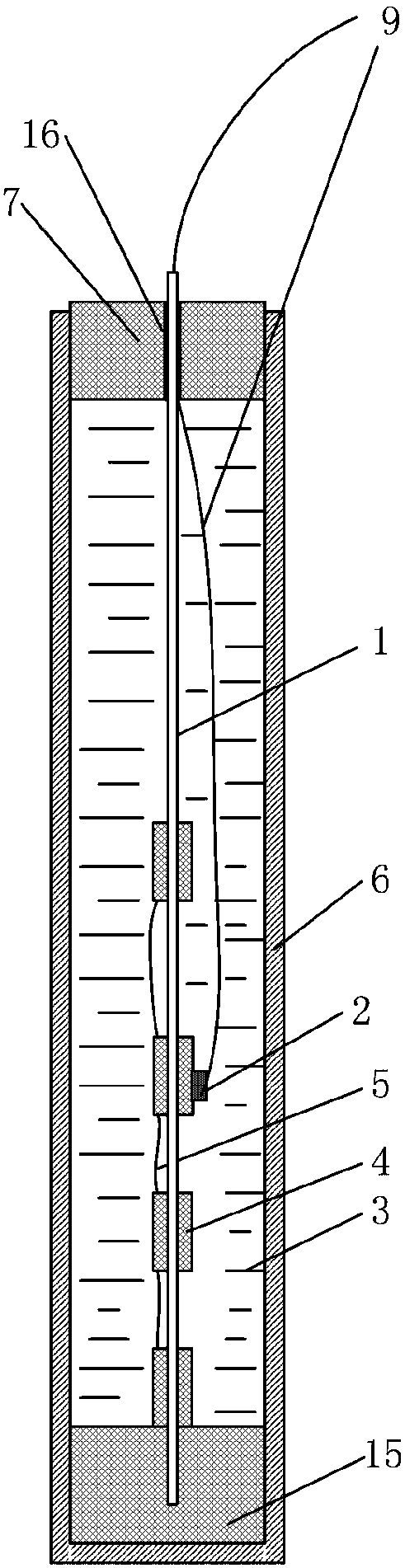

[0026] In order to achieve precise control of the effect of pre-splitting blasting and obtain an ideal blasting contour, the idea of this patent is to overcome the traditional random charging method and adopt a precisely designed charging structure to ensure the setting of the explosive in the blast hole. The blasting can be carried out at a certain position, and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com