Optical backplane interconnect system

An interconnection system and optical backplane technology, applied in the field of optical backplane interconnection systems, can solve the problems of increasing the number of copper wires, increasing the cost, and complex PCB board structure, and achieving the effect of simplifying the signal transmission channel and improving the electromagnetic compatibility performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

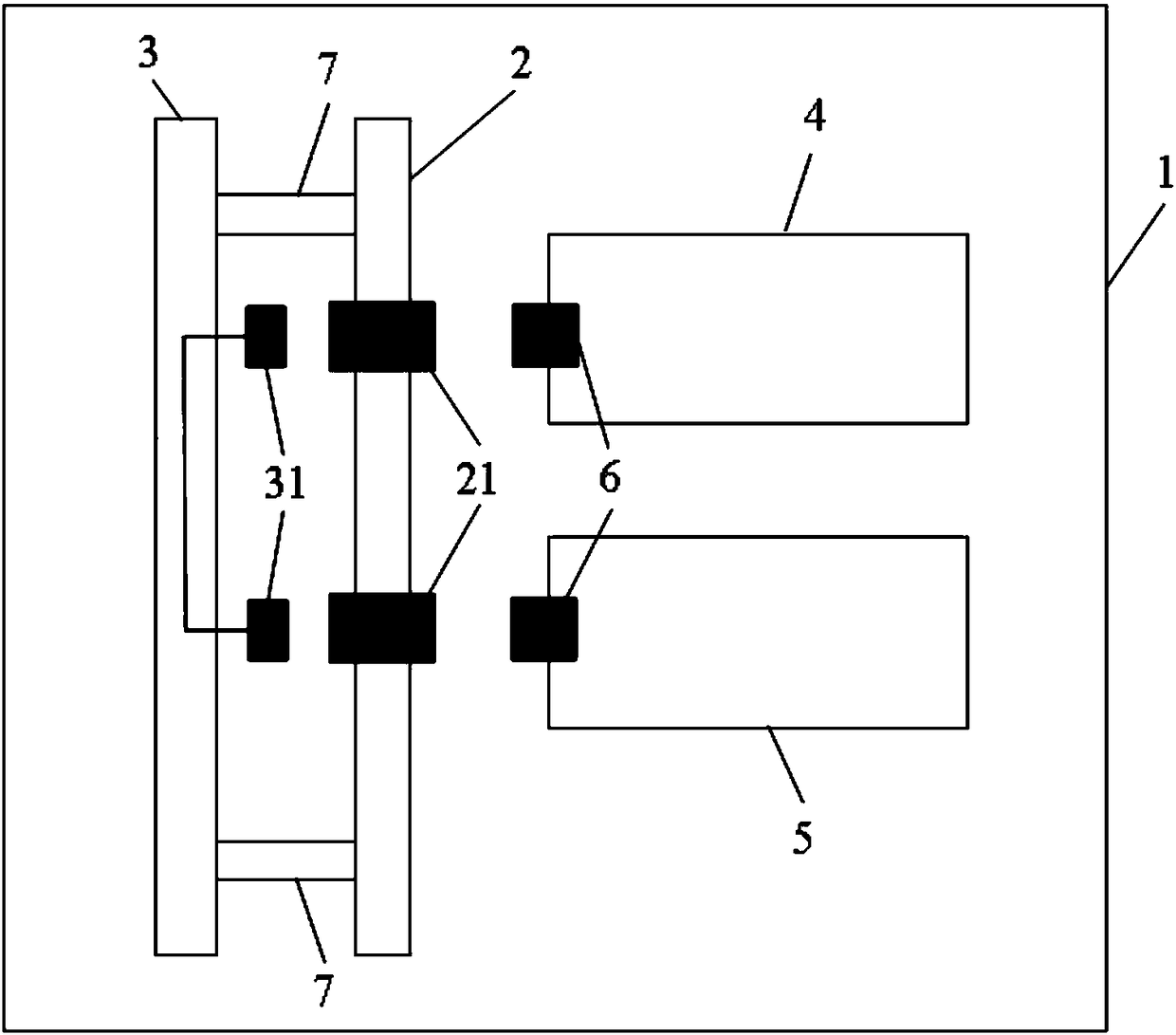

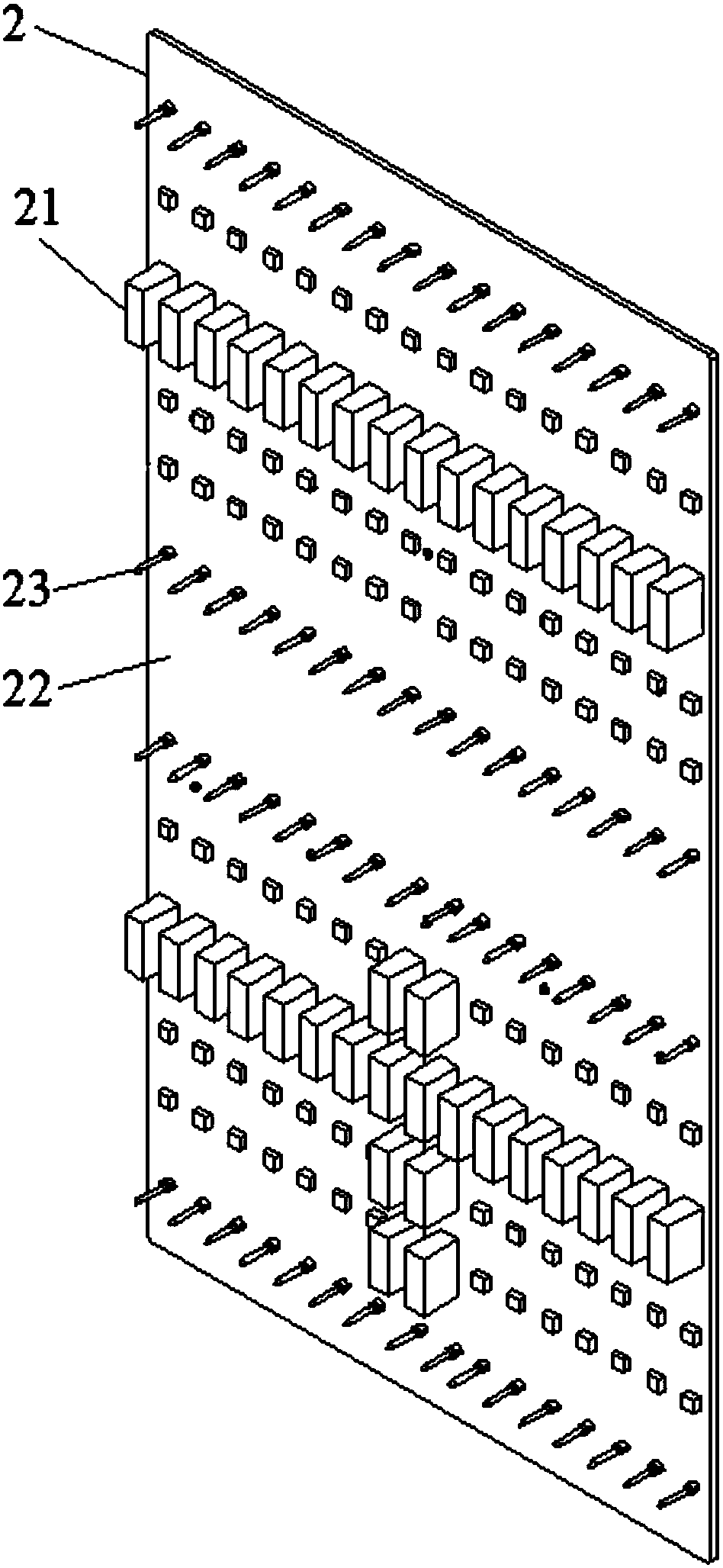

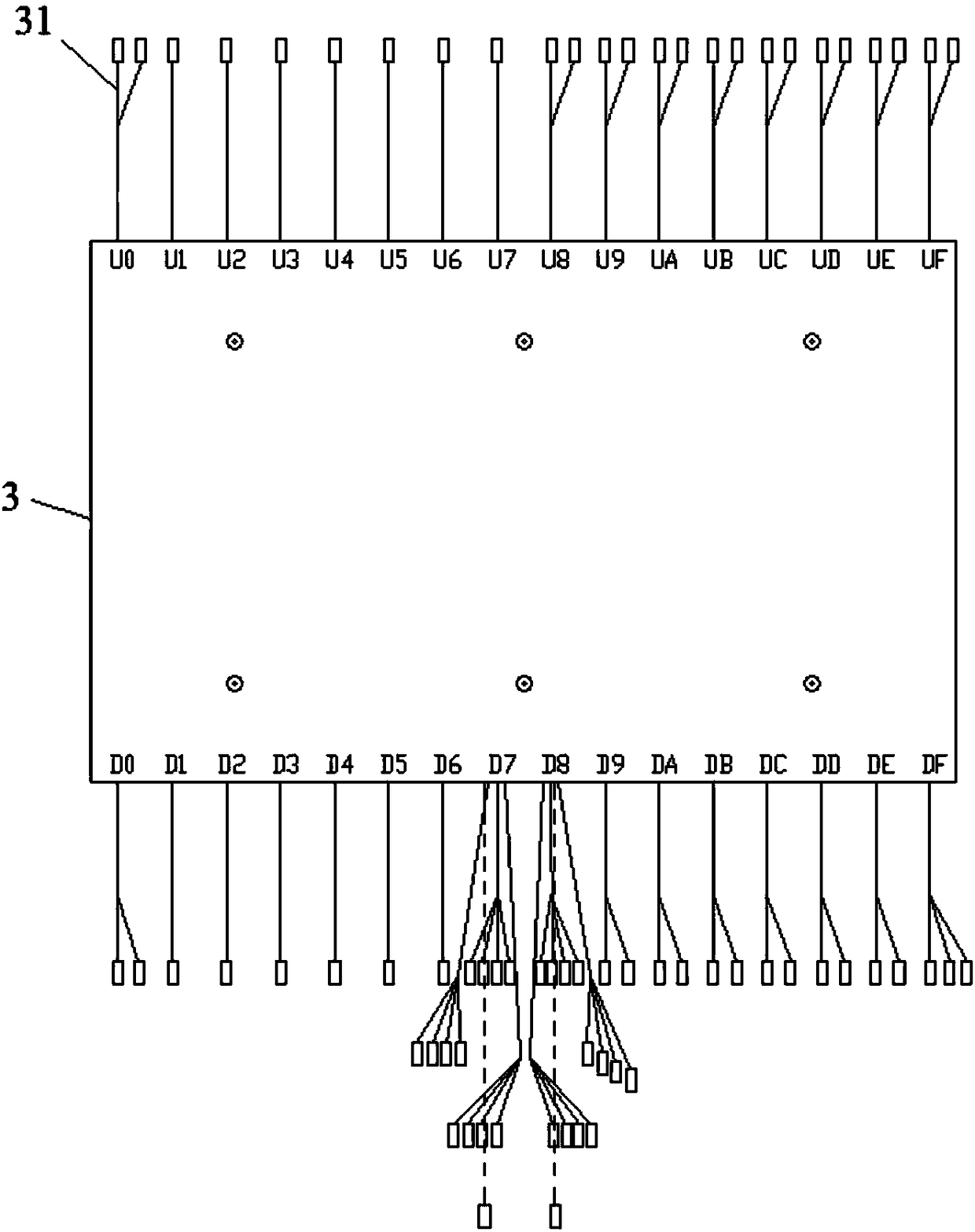

[0038] see Figure 1 to Figure 5 As shown, this embodiment provides an optical backplane interconnection system, which includes a subrack 1 , an electrical backplane 2 , an optical backplane 3 , an optical card 4 and an optical switch card 5 .

[0039] At least one electrical backplane 2 is fixed on the subrack 1 . The subrack 1 is mainly used to provide a supporting structure for the entire optical backplane interconnection system.

[0040] The optical backplane 3 is fixed on the subrack 1 and on one side of the electric backplane 2 , and optical fibers are arranged in the optical backplane 3 . The optical backplane 3 provides optical fiber routing for the entire optical backplane interconnection system.

[0041] The optical card 4 is fixed on the subrack 1 and located on the side of the electrical backplane 2 away from the optical backplane 3 , and the optical card 4 is connected to the optical backplane 3 through the electrical backplane 2 .

[0042] The optical switch c...

Embodiment 2

[0046] see Figure 1 to Figure 5 As shown, this embodiment provides an optical backplane interconnection system, which includes a subrack 1 , an electrical backplane 2 , an optical backplane 3 , an optical card 4 and an optical switch card 5 .

[0047] At least one electrical backplane 2 is fixed on the subrack 1 .

[0048] The optical backplane 3 is fixed on the subrack 1 and on one side of the electric backplane 2 , and optical fibers are arranged in the optical backplane 3 .

[0049] The optical card 4 is fixed on the subrack 1 and located on the side of the electrical backplane 2 away from the optical backplane 3 , and the optical card 4 is connected to the optical backplane 3 through the electrical backplane 2 .

[0050] The optical switch card 5 is fixed on the subrack 1 and is located on the side of the electric backplane 2 away from the optical backplane 3. The optical switch card 5 is connected to the optical backplane 3 through the electric backplane 2, and the opti...

Embodiment 3

[0058] see Figure 1 to Figure 5 As shown, this embodiment provides an optical backplane interconnection system, which includes a subrack 1 , an electrical backplane 2 , an optical backplane 3 , an optical card 4 and an optical switch card 5 .

[0059] At least one electrical backplane 2 is fixed on the subrack 1 .

[0060] The optical backplane 3 is fixed on the subrack 1 and on one side of the electric backplane 2 , and optical fibers are arranged in the optical backplane 3 .

[0061] The optical card 4 is fixed on the subrack 1 and located on the side of the electrical backplane 2 away from the optical backplane 3 , and the optical card 4 is connected to the optical backplane 3 through the electrical backplane 2 .

[0062] The optical switch card 5 is fixed on the subrack 1 and is located on the side of the electric backplane 2 away from the optical backplane 3. The optical switch card 5 is connected to the optical backplane 3 through the electric backplane 2, and the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com