Method for learning surface roughness of multi-parameter parts based on random forest

A technology of surface roughness and random forest, applied in computer parts, image data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

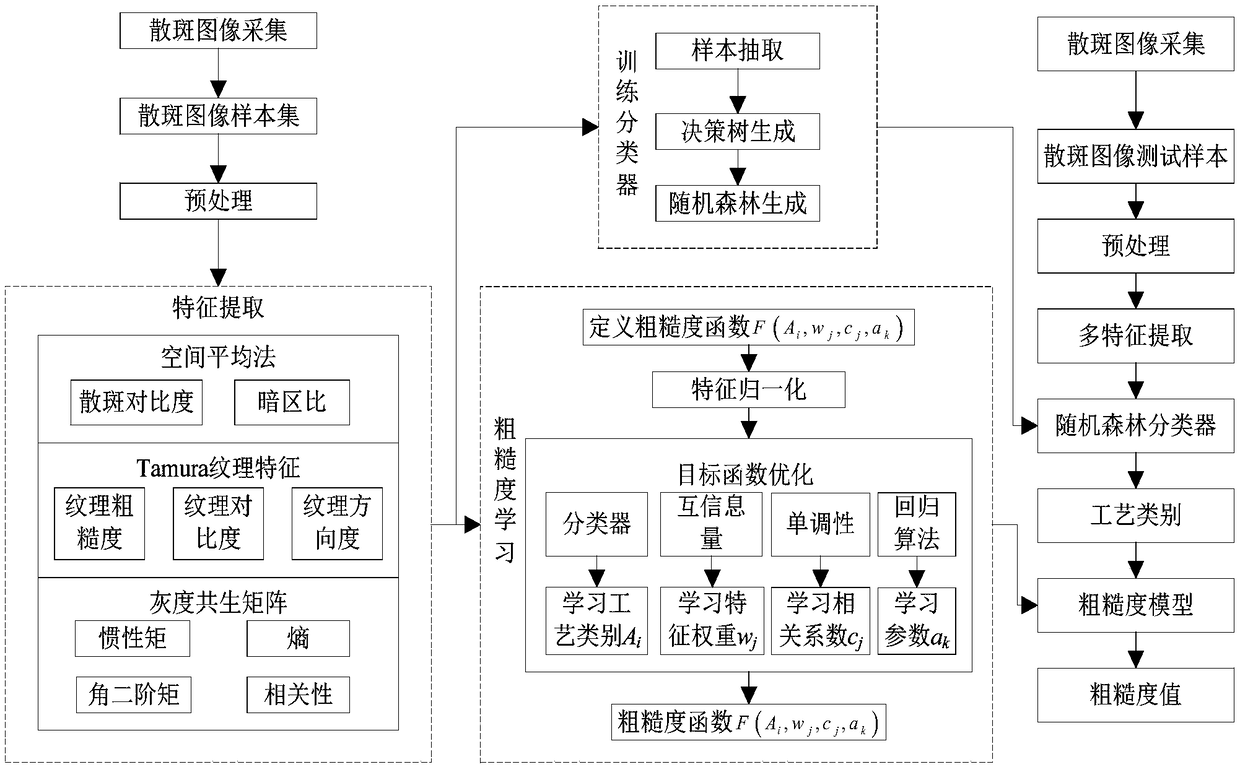

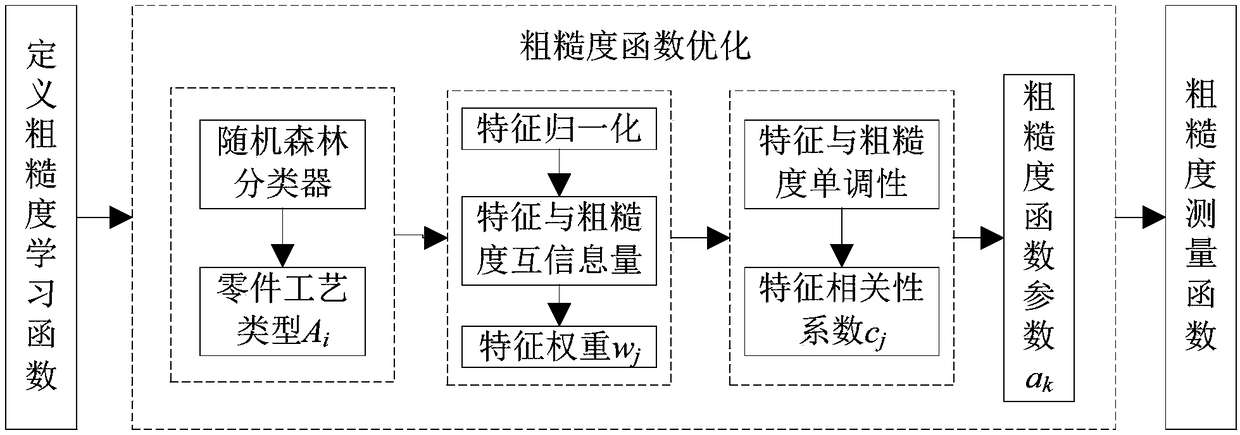

[0026] A random forest-based multi-parameter surface roughness learning method for parts, such as figure 1 shown, including the following specific steps:

[0027] Step 1, sample image acquisition, the speckle field generated by the laser irradiation on the surface of the object is collected by the CCD camera, and transmitted to the workstation through the image acquisition card;

[0028] Step 2, image preprocessing, to enhance the detail features of the shadow part of the image;

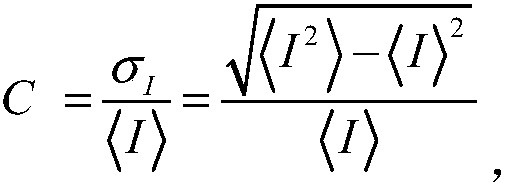

[0029] Step 3, multi-feature extraction, that is, using the spatial average method to extract the optical features, the gray level co-occurrence matrix method to extract the mean, variance, correlation, entropy, second-order moment, and inertia moment features, and the Tamura texture feature method to extract the texture features;

[0030] Step 4, adding each feature as an attribute to rand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com