A kind of preparation method of red heart kiwi fruit powder

A technology of red kiwifruit and kiwifruit, which is applied in the field of preparation of red kiwifruit powder, can solve problems such as easy occurrence of sticky pot, hanging on the wall, and decline of beneficial ingredients in finished products, and achieves simple and feasible preparation method, improved production efficiency, and superior brewing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

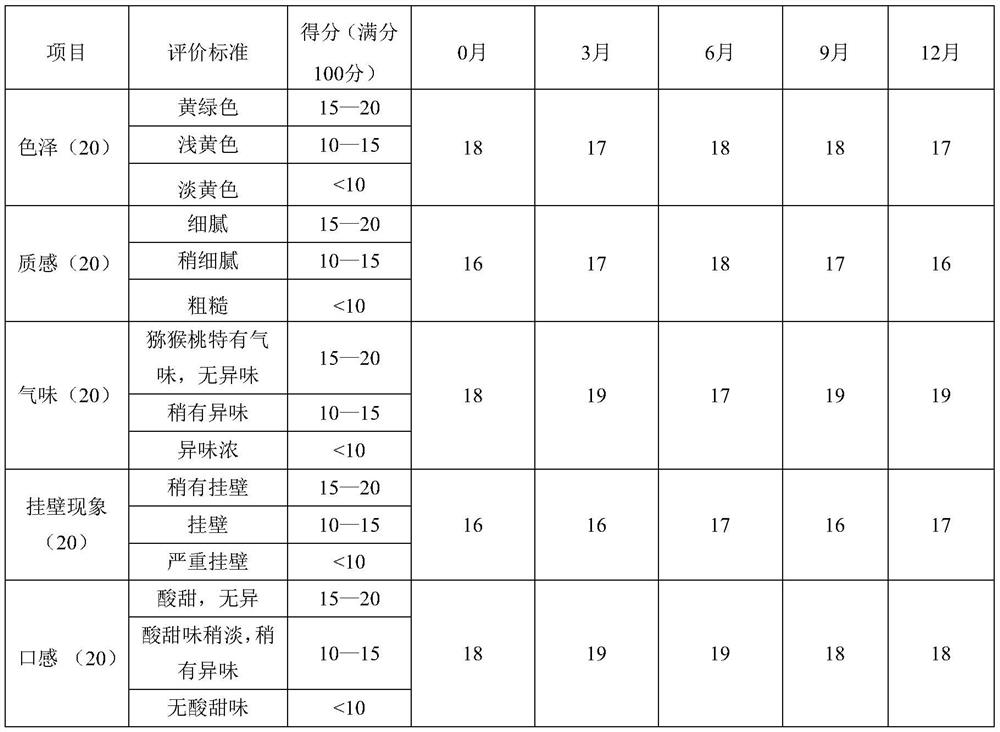

Examples

Embodiment 1

[0028] A kind of kiwifruit with red heart is prepared according to the following steps:

[0029] 1. Selection of kiwifruit raw materials: manual selection, selection of kiwi fruit with high maturity, for use;

[0030] 2. Cleaning: Manually wash with tap water to remove stains on the surface of kiwi fruit, and set aside;

[0031] 3. Peeling: Peel the kiwi fruit, collect the pulp, and set aside;

[0032] 4. Juicing: Take the peeled kiwi fruit pulp and add purified water, the mass ratio of kiwi fruit pulp to purified water is 1:1, and carry out the juicing treatment.

[0033] 5. Filtration: filter the juiced slurry with 100-mesh gauze, collect the filtrate, and obtain kiwi fruit juice 1, which is set aside;

[0034] 6. Add pectinase: first add 0.1mol / L citric acid solution to the kiwi fruit juice to adjust the pH to 3.3, then place it in a digital constant temperature electric hot water bath and heat it to 45°C. 0.4% of the mass of pectinase is then left to stand at 45°C for 3...

Embodiment 2

[0050] A kind of kiwifruit with red heart is prepared according to the following steps:

[0051] 1. Selection of kiwifruit raw materials: manual selection, selection of kiwi fruit with high maturity, for use;

[0052] 2. Cleaning: Manually wash with tap water to remove stains on the surface of kiwi fruit, and set aside;

[0053] 3. Peeling: Peel the kiwi fruit, collect the pulp, and set aside;

[0054] 4. Juicing: Take the peeled kiwi fruit pulp and add purified water, the mass ratio of kiwi fruit pulp to purified water is 1:0.8, and carry out the juicing treatment.

[0055] 5. Filtration: filter the juiced slurry with 100-mesh gauze, collect the filtrate, and obtain kiwi fruit juice 1, which is set aside;

[0056] 6. Add pectinase: first add 0.05mol / L citric acid solution to the kiwi fruit juice to adjust the pH to 3.5, then place it in a digital constant temperature electric hot water bath and heat it to 40°C. 0.3% of the mass of pectinase is then left to stand at 40-50°C...

Embodiment 3

[0064] A kind of kiwifruit with red heart is prepared according to the following steps:

[0065] 1. Selection of kiwifruit raw materials: manual selection, selection of kiwi fruit with high maturity, for use;

[0066] 2. Cleaning: Manually wash with tap water to remove stains on the surface of kiwi fruit, and set aside;

[0067] 3. Peeling: Peel the kiwi fruit, collect the pulp, and set aside;

[0068] 4. Juicing: Take the peeled kiwi fruit pulp and add purified water, the mass ratio of kiwi fruit pulp to purified water is 1:1.5, and carry out the juicing treatment.

[0069] 5. Filtration: filter the juiced slurry with 100-mesh gauze, collect the filtrate, and obtain kiwi fruit juice 1, which is set aside;

[0070] 6. Add pectinase: first add 0.20mol / L citric acid solution to the kiwi fruit juice to adjust the pH to 3.0, then place it in a digital constant temperature electric hot water bath and heat it to 50°C. 0.5% of the mass of pectinase is then left to stand at 50°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com