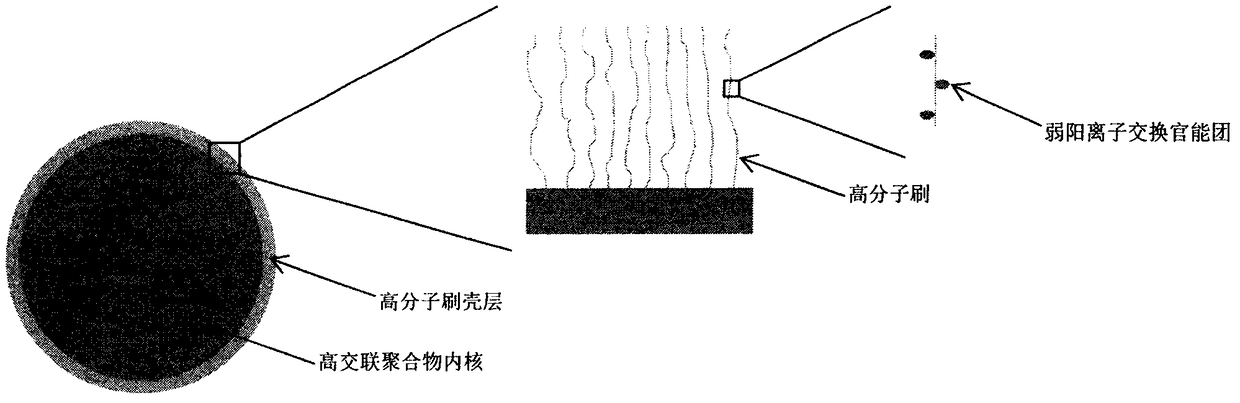

Preparation method of core-shell type weak cation exchange resin microspheres having surfaces with polymer brushes

A weak cation exchange and resin microsphere technology is applied in the field of preparation of core-shell type weak cation exchange resin liquid chromatography packing, which can solve the problems of inorganic silica gel not resistant to acid and alkali, poor chemical stability, etc., and achieve acid and alkali resistance. The effect of wide range, good monodispersity and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of highly cross-linked cores

[0032] Highly cross-linked core microspheres were prepared by the method (distillation precipitation polymerization method) described in the non-patent literature [Donglai Qi, Feng Bai, Xinlin Yang, Wenqiang Huang, European Polymer Journal 2005, 41:2320.].

[0033] Divinylbenzene (DVB80) (70mL, 64.0g, 0.49mol, 2.5vol% relative to the total volume of the reaction solution) and AIBN (1.75g, 10.65mmol, 2.73wt% relative to the total amount of monomers), dispersed in 2800mL acetonitrile middle. Place it in a clean 5L three-necked round-bottomed flask, and install a fractionating column, a condenser tube and a receiving bottle. The reaction flask was placed in an electric heating mantle and heated slowly, from room temperature to boiling within 30 minutes, and began to evaporate the solvent, and controlled to evaporate 1400mL of acetonitrile within 2 hours to stop the reaction. When the reaction system is down to room temperature, ...

Embodiment 1

[0034] Example 1 Using traditional free radical surface polymerization, grafting polyacrylic acid directly on the surface of Poly(DVB80) core

[0035] Take 5.6 g of Poly(DVB80) core microspheres and put them into a 1000 mL pear-shaped bottle, add 640 mL of acetonitrile, and disperse the core microspheres evenly in the acetonitrile by ultrasonic vibration, then add 7.2 mL of acrylic acid (7.56 g, 104.9 mmol) and AIBN (0.151g, 0.92mmol, 2wt% relative to the amount of acrylic acid), the pear-shaped bottle is connected to a rotary evaporator and immersed in an ice-water bath, while rotating the pear-shaped bottle, the reaction system is vacuumed and nitrogen-filled for three times , to remove the oxygen in the system, and then the system is always protected under nitrogen atmosphere. Control the rotation speed of the pear-shaped bottle to 90rpm, raise the system temperature to 70°C within 1 hour, and keep it at 70°C for 10 hours. When the reaction system drops to room temperature,...

Embodiment 2

[0036] Example 2 In the process of grafting polyacrylic acid on the surface of Poly(DVB80) core, add RAFT reagent to control the polymerization reaction of acrylic acid

[0037]Take 5.6g of Poly(DVB80) core microspheres into a 1000mL pear-shaped bottle, add 560mL of acetonitrile, and disperse the core microspheres evenly in the acetonitrile by ultrasonic vibration, then add 34.3mL of acrylic acid (36g, 500mmol), cyanomethyl Dodecyl trithiocarbonate (0.318g, 1mmol) and AIBN (54.7mg, 0.33mmol), the pear-shaped flask was connected to the rotary evaporator and immersed in an ice-water bath, while rotating the pear-shaped flask, the reaction The system was vacuum pumped and filled with nitrogen three times to remove oxygen in the system, and then the system was always protected under a nitrogen atmosphere. Control the rotation speed of the pear-shaped bottle to 90rpm, and react at 70°C for 2 hours. When the reaction system drops to room temperature, the reactant is filtered through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap