Quick knife falling device

A tool drop and fast technology, applied in the direction of auxiliary devices, accessories of toolholders, turning equipment, etc., to achieve the effect of sensitive and fast response, simple action, simple and accurate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

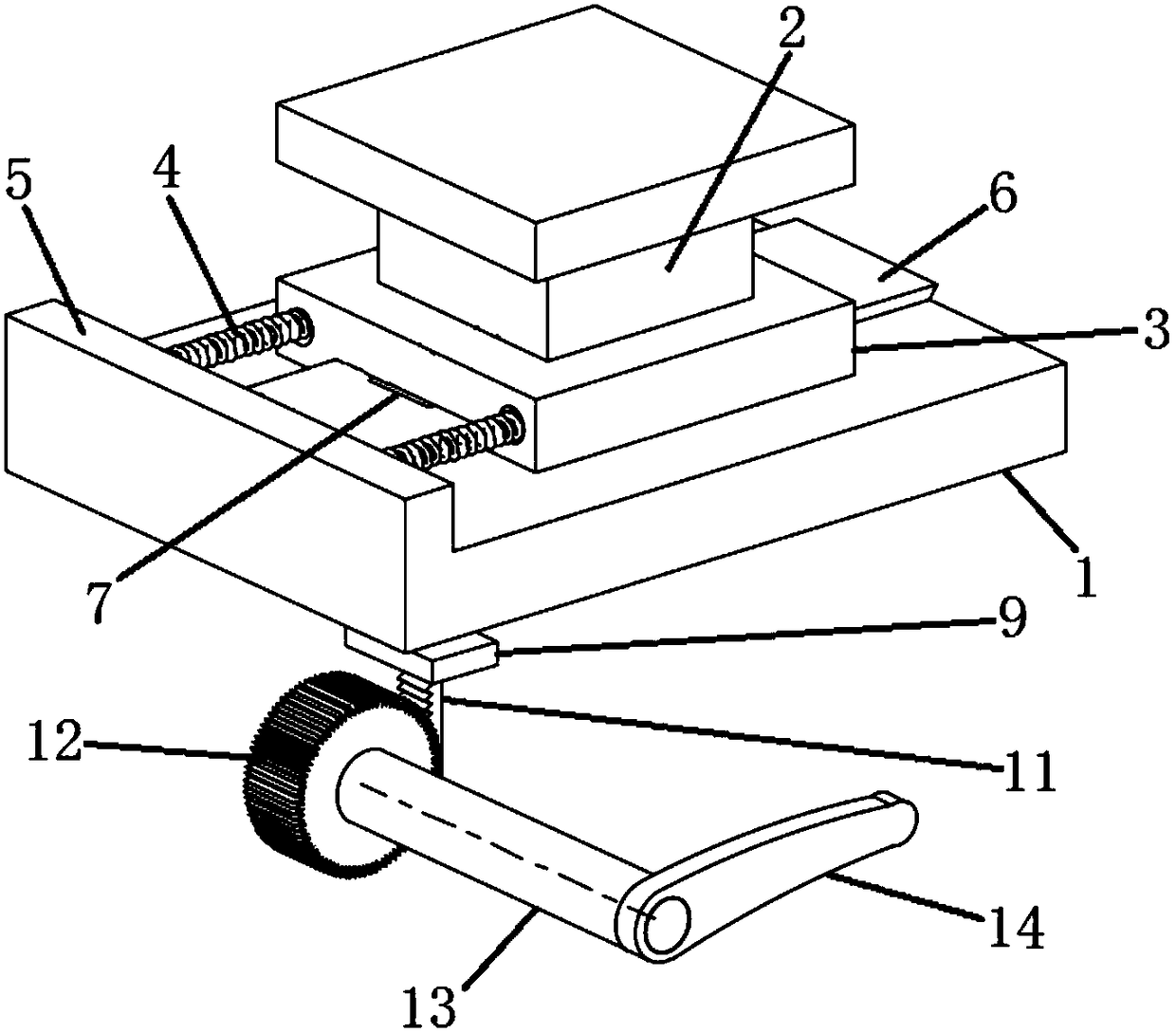

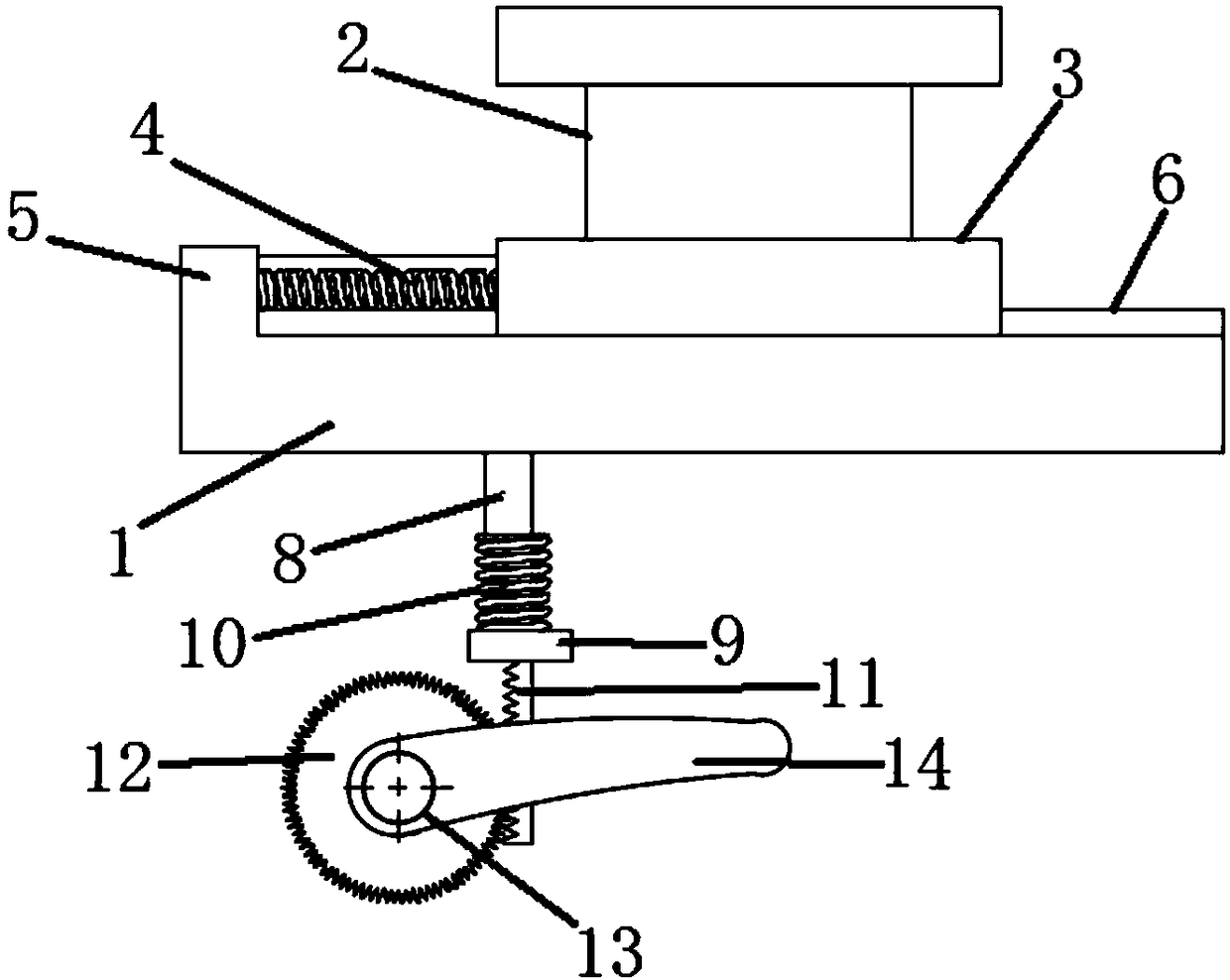

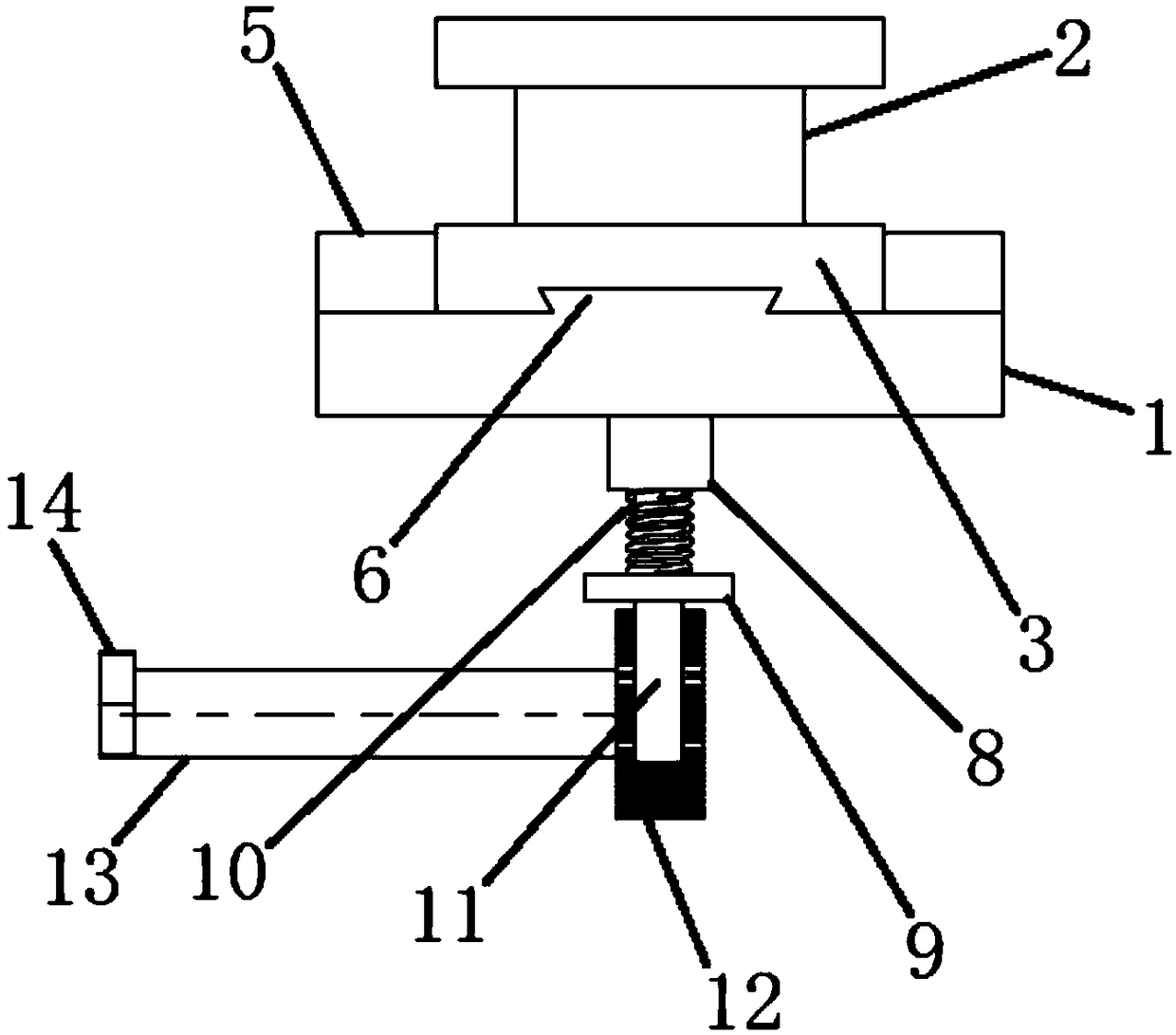

[0031] Such as figure 1 , figure 2 , image 3 A rapid knife drop device is shown, which includes a base 1, a spring push knife drop mechanism slidably arranged on the base 1, and a knife drop control mechanism arranged at the bottom of the base 1 and matched with the spring push knife drop mechanism, A clamp 2 is arranged on the spring pushing and falling knife mechanism.

[0032] Wherein, the spring pushing and dropping mechanism includes a slider 3 slidably arranged on the base 1 and a pressure spring 4 arranged between one end of the slider 3 and the base 1 , and the clamp 2 is arranged on the slider 3 . The base 1 is provided with a pressure spring mounting block 5 , one end of the pressure spring 4 is fixedly connected with the pressure spring mounting block 5 , and the other end is fixedly connected with the slider 3 . A pair of pressure springs 4 are juxtaposed between the pressure spring mounting block 5 and the slider 3 . The base 1 is provided with a guide block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com