Vertical-type high-pressure water cutting device

A technology of cutting equipment and high-pressure water, which is applied to metal processing equipment, used abrasive processing devices, abrasives, etc., can solve the problems of worker hazards, low efficiency, and high error rate, and achieve the protection of hazards and the stability of the path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

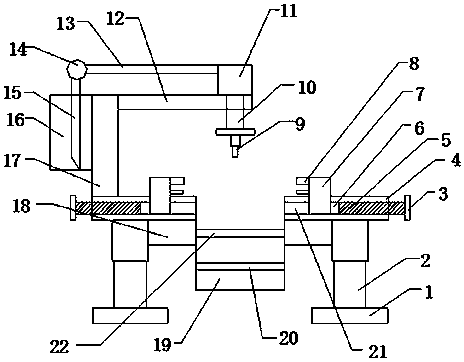

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0015] Such as figure 1 As shown, a vertical high-pressure water cutting equipment is characterized in that it includes a support 2, a water storage tank 19, a support platform 4 and a cutting gun 9, and the support 2 is provided with four vertically placed on the ground, and the support 2. Rivet the support platform 4 on the top, the support platform 4 is set as a flat cuboid, and the middle bottom is connected to the entrance of the water storage tank 19; the center of the left and right ends of the support platform 4 is horizontally provided with a cavity 21, and the cavity 21 is internally provided with Moving block 7, the upper left corner of moving block 7 is provided with a splint 8, the lower right corner of the moving block 7 is riveted with the rotator 6, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com