Tetrahedral drip irrigation bag and manufacturing method thereof

A tetrahedral and body-shaped technology, which is applied in bag making operations, bags, sacks, etc., can solve the problems of insufficient support force of drip irrigation bags, achieve the effect of increasing height difference, increasing water outlet pressure, and facilitating water filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

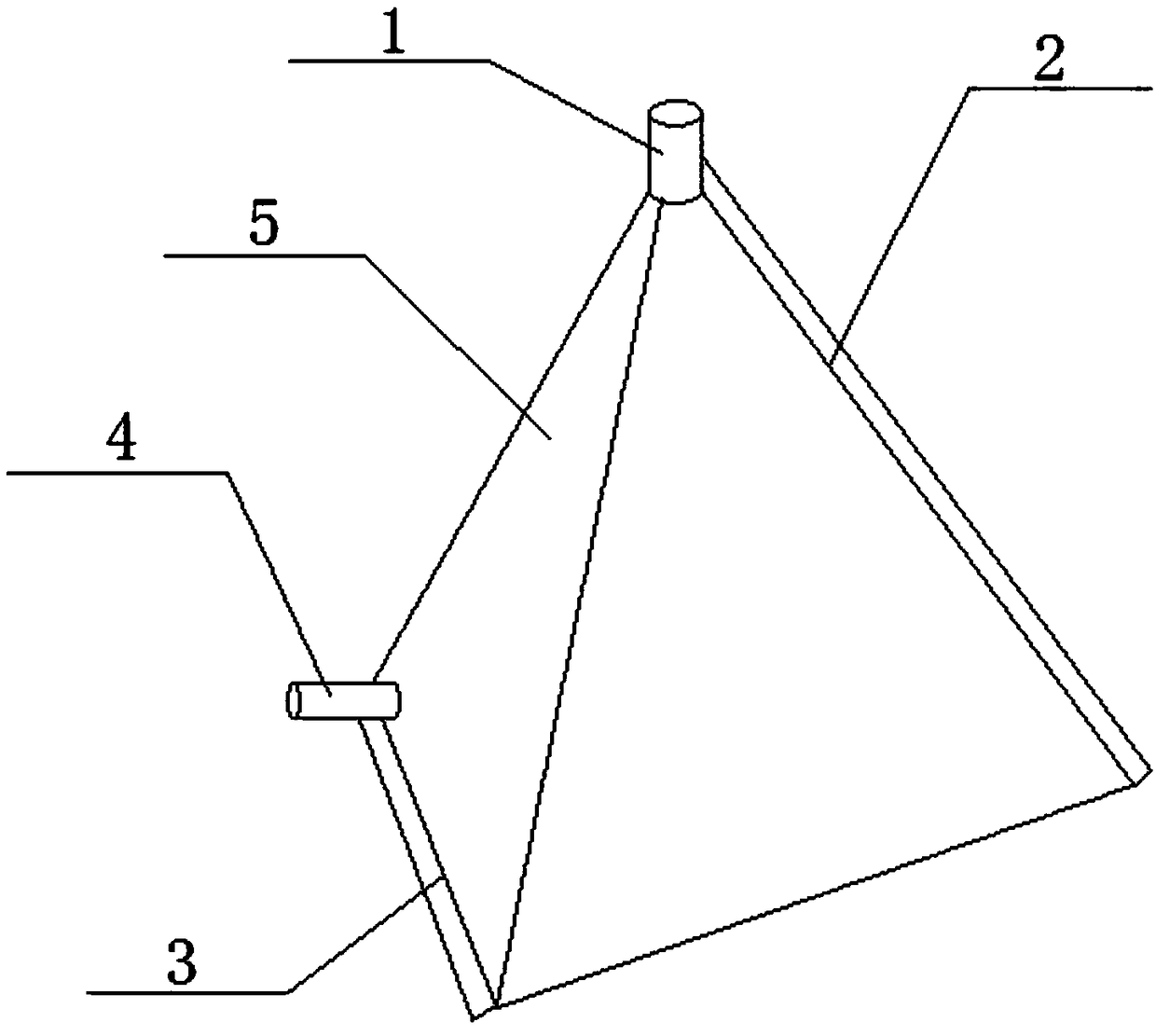

[0021] Such as figure 1 As shown, a tetrahedral drip irrigation bag includes four regular triangular faces 5, a water inlet 1 and a water outlet 4, and is characterized in that: the three sides of each said regular triangular face 5 are connected with the other three regular triangular faces 5 respectively. One side of each side is affixed, and a water inlet 1 is arranged on one vertex of a tetrahedron formed by three equilateral triangular faces 5, and a water outlet 4 is arranged on the other vertex;

[0022] The equilateral triangle is made of plastic film;

[0023] The tetrahedron is formed by vertically thermally bonding different surfaces of the sides formed by pressing the two ends of the cylindrical plastic film.

[0024] The manufacturing method of the tetrahedral drip irrigation bag is characterized in that it comprises the following steps:

[0025] The first step, select the cylindrical plastic film as the raw material, measure the cylindrical plastic film that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com