Graphene preparation system

A preparation system, graphene technology, applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of no effective measures to prevent blockage and local accumulation, insufficient vibration, low production efficiency of graphene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

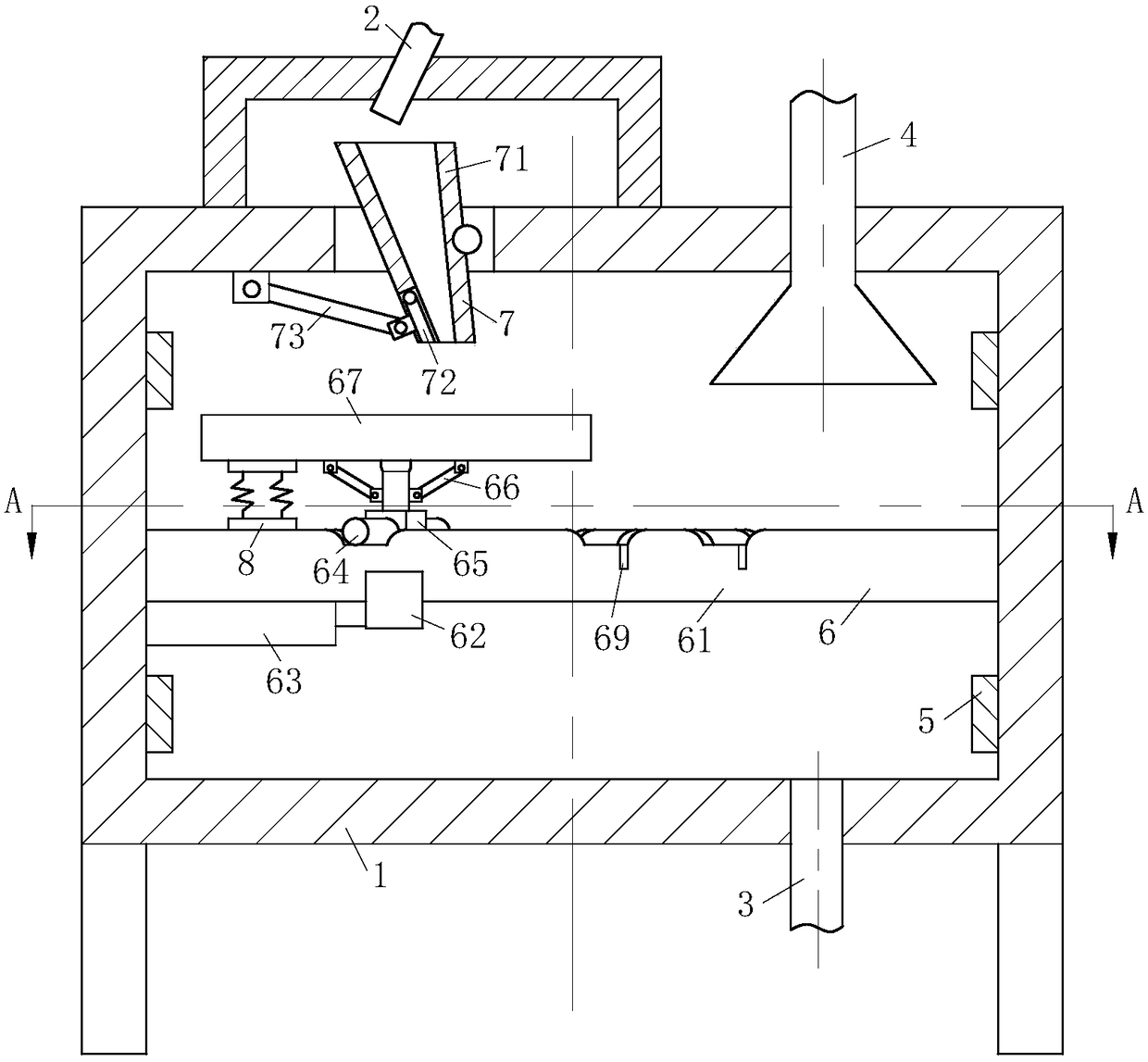

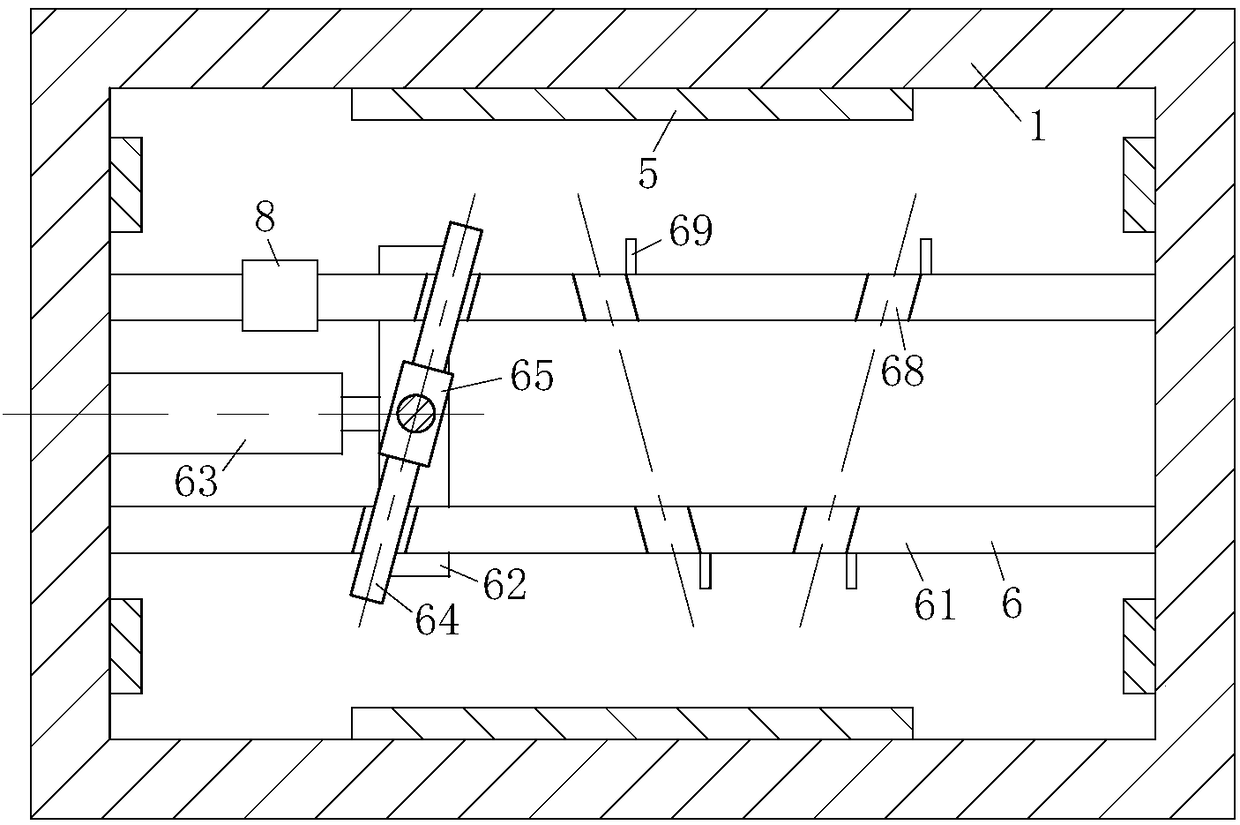

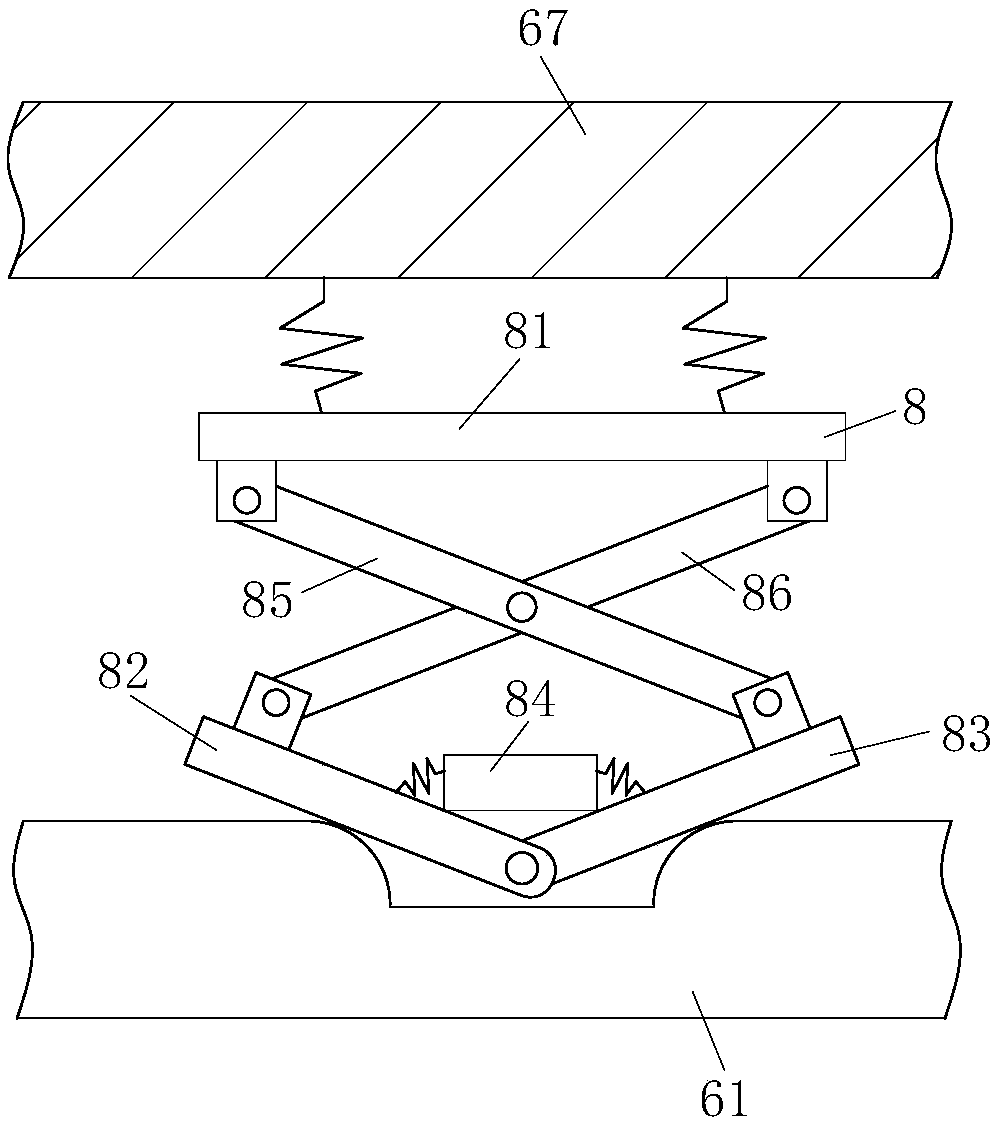

[0024] Such as Figure 1 to Figure 4 As shown, a kind of graphene preparation system of the present invention comprises box body 1, feed pipe 2, air inlet pipe 3, finished product conveying pipe 4, microwave launcher 5 and swing module 6; Said box body 1 top is set Feeding pipe 2; the bottom of the box body 1 is provided with an air inlet pipe 3, and the air inlet pipe 3 can inject inert gas or compressed air into the box body 1; The top of the box 1; the inner wall of the box 1 is provided with a microwave transmitter 5; the swing module 6 is arranged in the middle of the box 1, and the swing module 6 is used to place oxidized graphite particles; the swing module 6 includes a cross bar 61, a slider 62, a push rod 63, a roller 64, a mounting bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com