Bionic forklift-type deep sea small and medium-sized seawater desalination apparatus

A small and medium-sized, forklift technology, applied in seawater treatment, general water supply conservation, chemical instruments and methods, etc., can solve the problems of dead filter, poor adaptability, unsuitable for small and medium-sized seawater desalination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

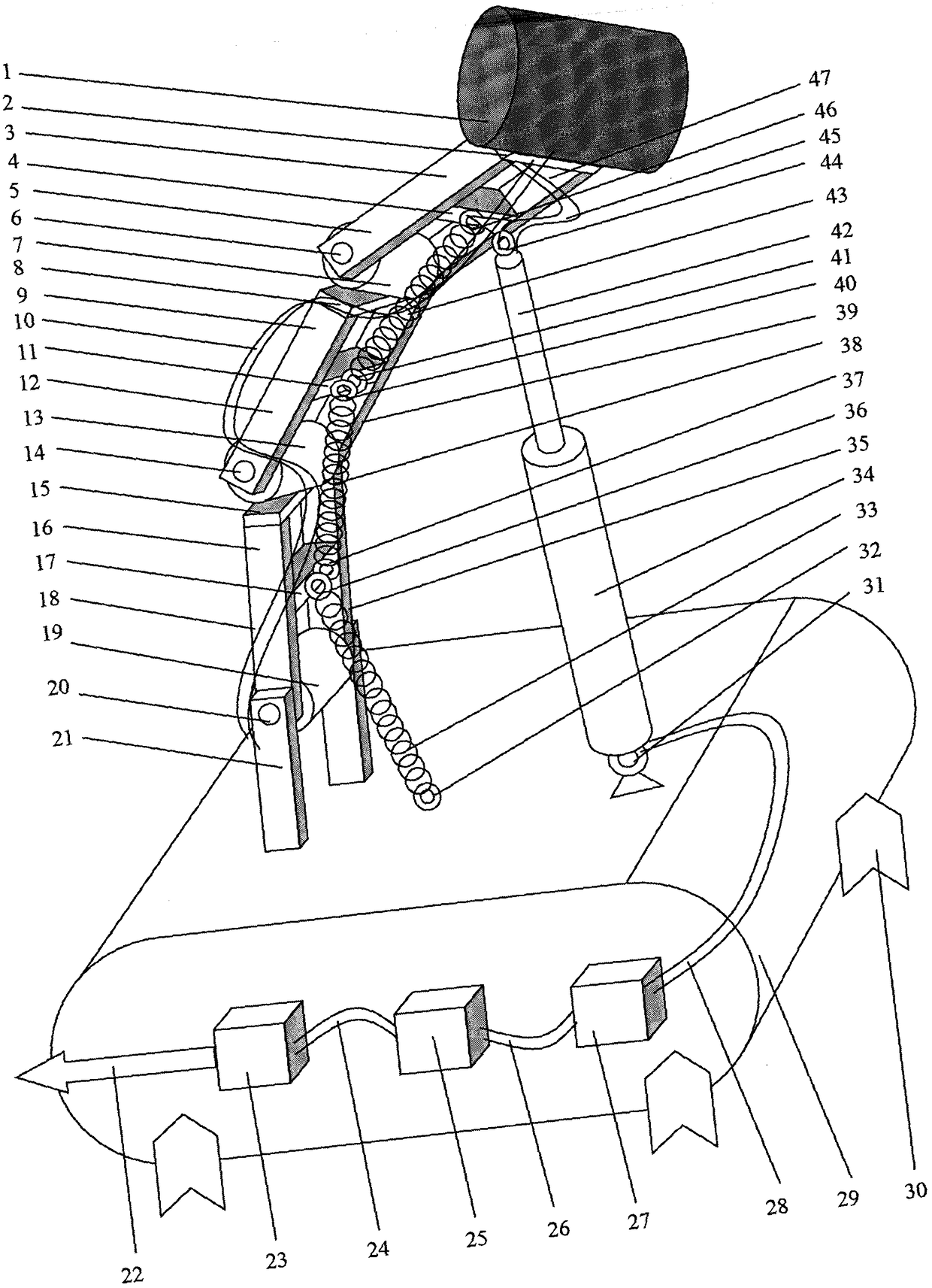

[0020]The specific embodiment of the present invention is, set imitation forklift type overall structure, imitation forklift type overall structure is by imitation bucket type pretreatment filter cartridge 1, forklift small arm structure 5, forklift middle arm structure 12, forklift large The arm structure 18 is composed of a forklift body-type sterilization and purification box 29, and the forklift forearm structure 5 is composed of the upper rod I2, the middle beam I4, the left rod I3, the right rod I47 and the swing pressurization cylinder I6. The arm structure 12 is the same as the forklift small arm structure 5, and the forklift large arm structure 18 is set to be the same as the forklift small arm structure 5, and the middle beam I4 of the forklift small arm structure 5 and the middle beam II17 of the forklift middle arm structure 12 are set Between the fixed ring VI46, the fixed ring V41 is connected to the upper tension spring 43, the middle beam II11 of the forklift mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com