Structure for quickly splicing prefabricated pier and prefabricated bearing platform and construction method of structure

A prefabricated platform and quick splicing technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of many uncertain factors, heavy prefabricated piers, and many pre-embedded steel bars, etc., to achieve strong connection reliability, Shorten the construction period and improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

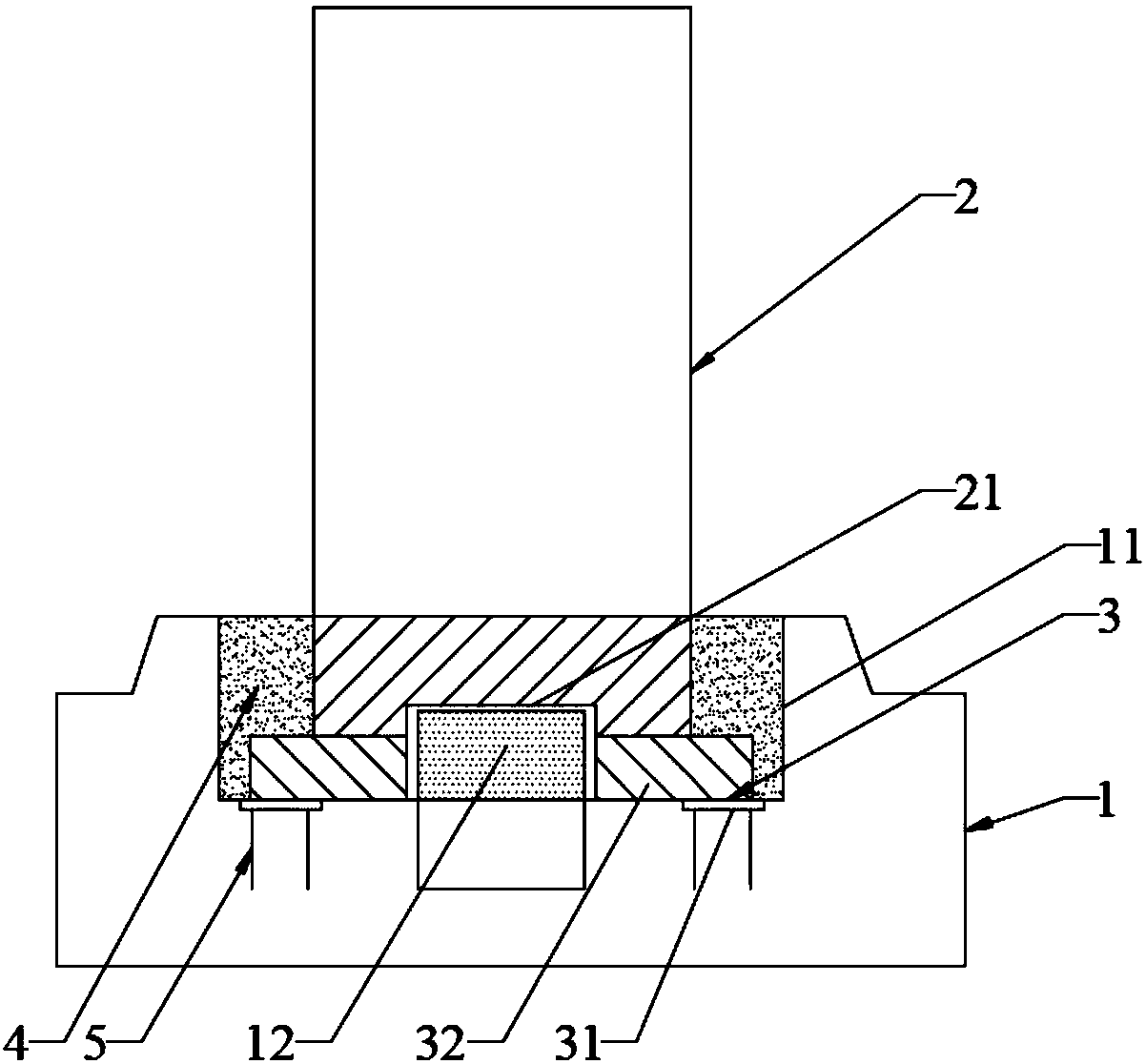

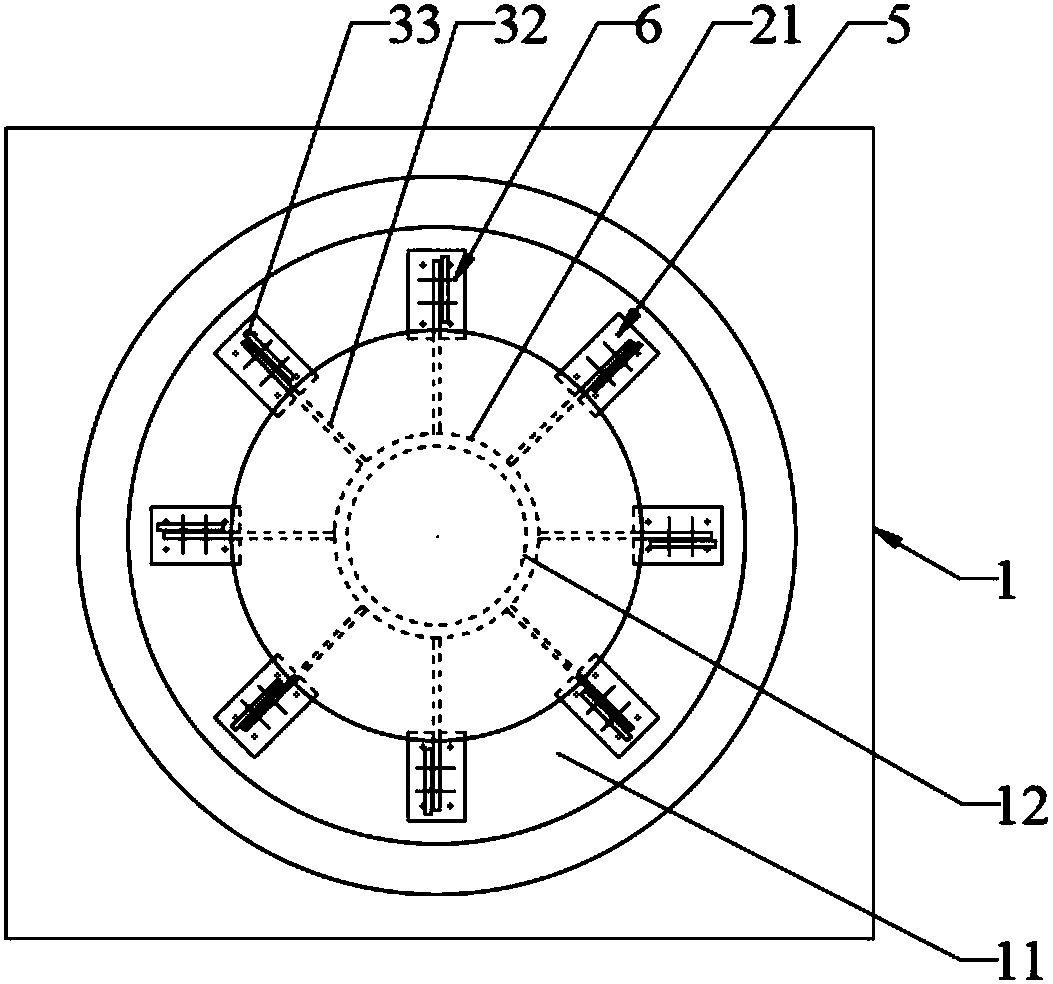

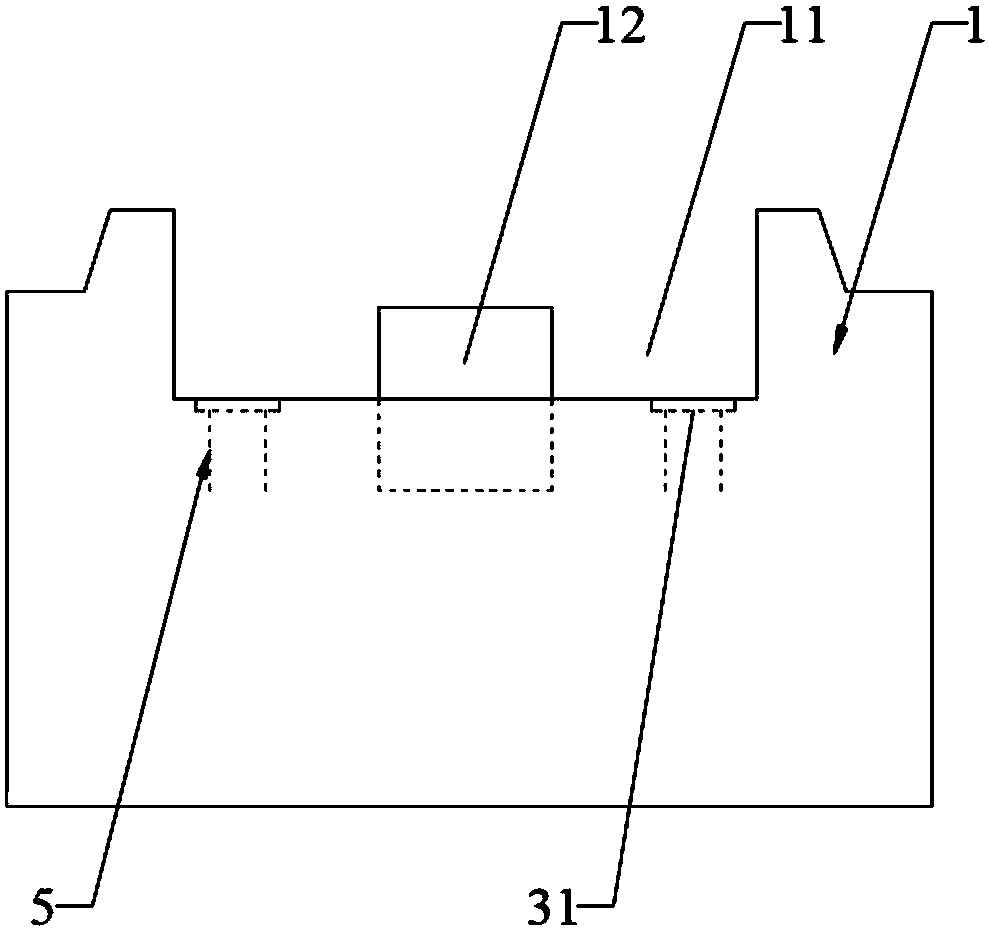

[0055] Please refer to figure 1 with figure 2 As shown, a prefabricated bridge pier and a prefabricated platform fast splicing structure, including a prefabricated platform 1, a prefabricated bridge pier 2 and a steel plate assembly 3; the prefabricated platform 1 is provided with a platform groove 11 with an upward opening, the The middle part of the platform groove 11 is provided with a steel pipe concrete tenon 12; the prefabricated pier 2 is vertically arranged and the prefabricated pier 2 is pre-embedded with a hollow steel pipe 21 arranged in the vertical direction, and the hollow steel pipe 21 is located in the prefabricated In the middle of the pier 2 and the lower surface of the hollow steel pipe 21 is flush with the lower surface of the prefabricated pier 2, the prefabricated pier 2 is sleeved on the steel pipe concrete tenon 12 of the prefabricated cap 1 through the hollow steel pipe 21, so The lower surface of the prefabricated pier 2 is flush with the horizontal...

Embodiment 2

[0060] The present invention also provides a construction method for the rapid splicing of prefabricated bridge piers 2 and prefabricated caps 1, which includes the following steps:

[0061] Step 1. Fix the prefabricated cap 1, and fix the prefabricated pier 2 on the prefabricated cap 1 by nesting the steel pipe concrete tenon 12 on the cap groove 11 with the hollow steel pipe 21 of the prefabricated pier 2;

[0062] Step 2. Weld the first steel plate 31 pre-embedded on the prefabricated cap 1 and the second steel plate 32 pre-embedded on the prefabricated pier 2, and weld the third steel plate 33 on the first steel plate 31 pre-embedded on the prefabricated cap 1 , and connected with the second steel plate 32 pre-embedded on the prefabricated pier 2 through bolts 6;

[0063] Step 3: Pour self-compacting concrete 4 whose strength level is one level higher than that of the prefabricated pier 2 between the cap groove 11 and the prefabricated pier 2 .

[0064] To sum up, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com