Seesaw type iron cylinder high-lift air compression water conveying device

A high-lift, see-saw technology, which is applied to the components of the pumping device for elastic fluids, the variable-capacity pump components, the machine/engine, etc. To achieve the effect of high lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

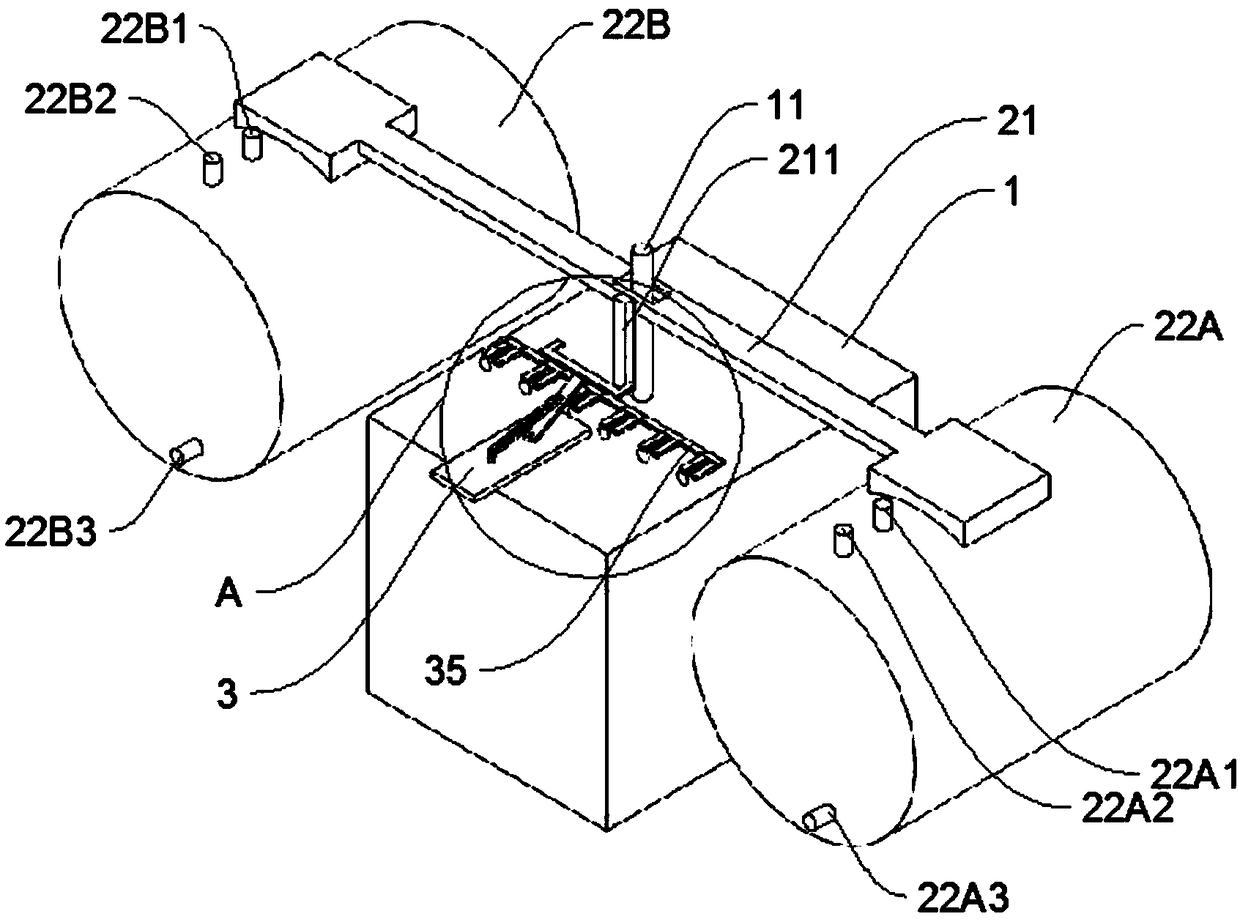

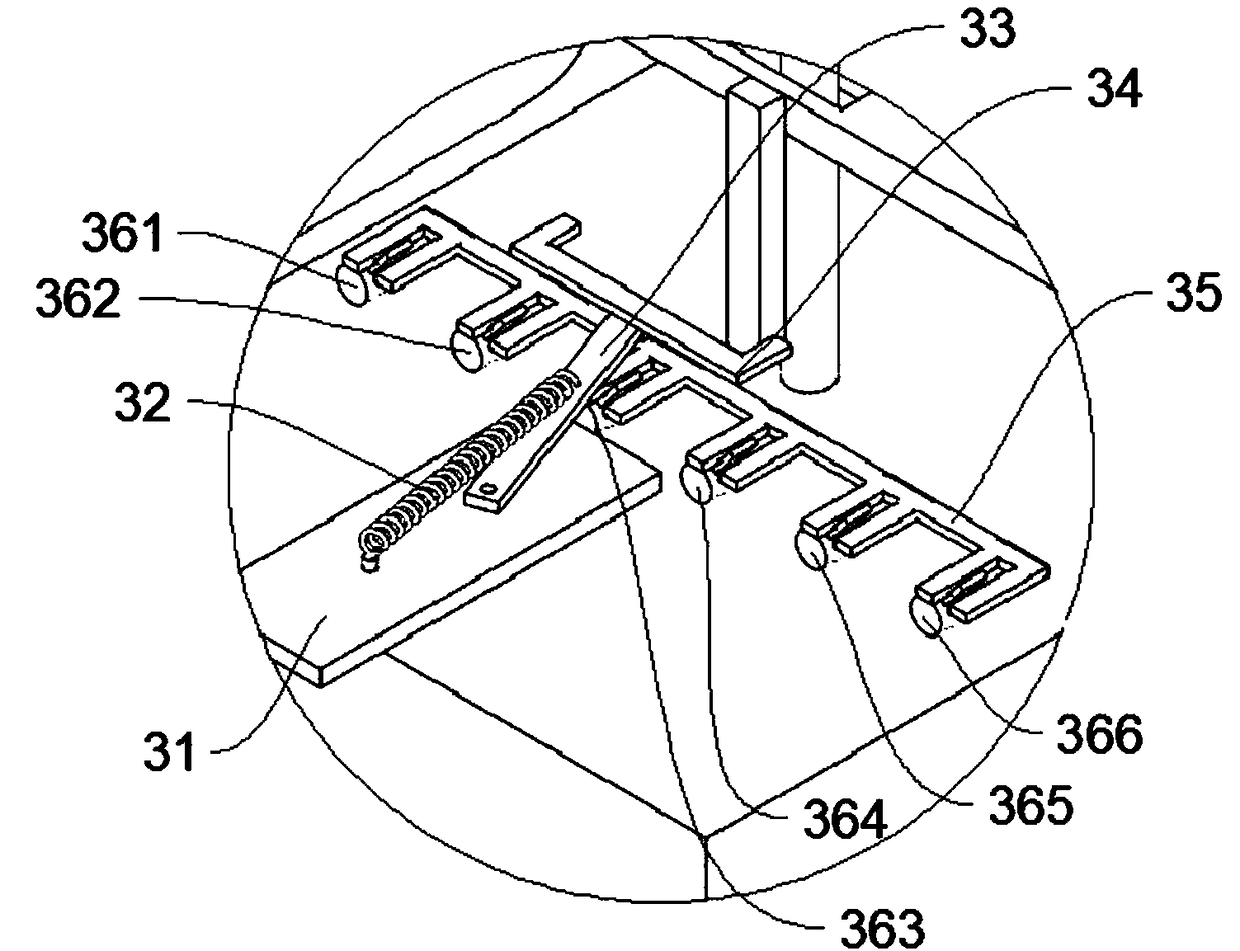

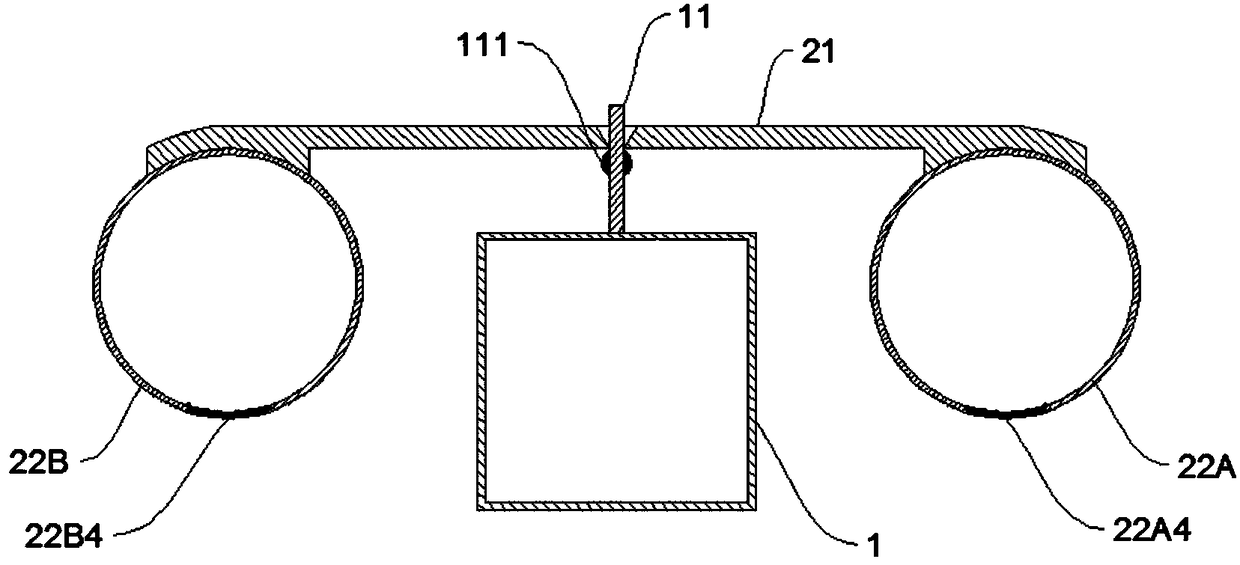

[0017] A seesaw type iron cylinder high-lift air pressure water supply device, comprising a buoyancy tank 1, a support rod 11 is arranged in the middle of the top surface of the buoyancy tank 1, and the middle part of the seesaw rod 21 passes through the support rod 11 through a through hole and can be connected with the support rod 11 The two ends of the seesaw rod 21 respectively fix the first iron cylinder 22A and the second iron cylinder 22B, and the bottoms of the first iron cylinder 22A and the second iron cylinder 22B are respectively provided with a first water inlet 22A4 and a second water inlet 22B4, the middle part of the seesaw bar 21 is provided with a vertically downwardly arranged driving lever 211, and the top surface of the buoyancy tank 1 is also provided with a spring machine 3 and a valve. 33. The middle part of the swing rod 33 is connected to the bottom plate 31 through the spring 32, the lower part of the swing rod 33 is pivotally connected with the long ...

Embodiment 2

[0026] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the structure of the driving rod 211 is different from that of the long connecting rod 35; The lower part is provided with a shift fork structure, and the long connecting rod 35 is provided with two fork blocks 351 to replace the second shift fork in embodiment 1, the space between the two fork blocks 351, when the fork 35 is When the driving lever 211 slowly rotates towards the 12 o'clock direction, the pendulum 35 moves in the space between the bar stoppers 351, which does not make the long connecting rod 35 move, only the pendulum 35 rotates rapidly immediately after passing the 12 o'clock direction , the swing rod 35 will be in contact with the swing rod stopper 351 to drive the long connecting rod 35 to move, and the long connecting rod 35 will be connected with the handle of the valve to control the valve. The rotation angle of fork 33 is then controlled by the blocking bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com