C-band electrically controlled cavity filter

A cavity filter and C-band technology, which is applied in the field of electronically tuned cavity filters, can solve the problems of Q value deterioration, mechanical frequency hopping filter frequency hopping accuracy error, poor filtering effect, etc., and achieve low Q value. Effects of deterioration, good VSWR, and small in-band insertion loss fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

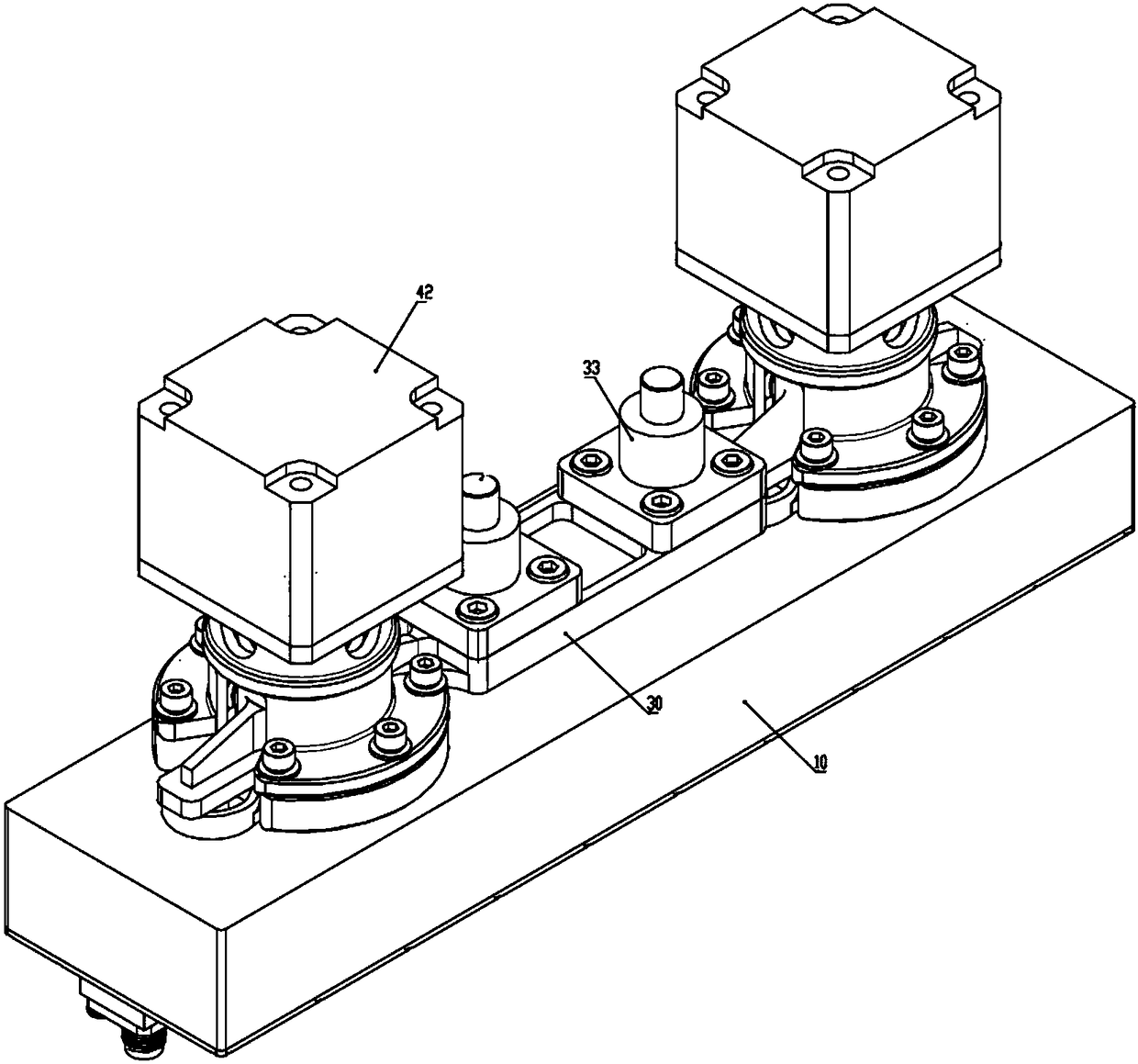

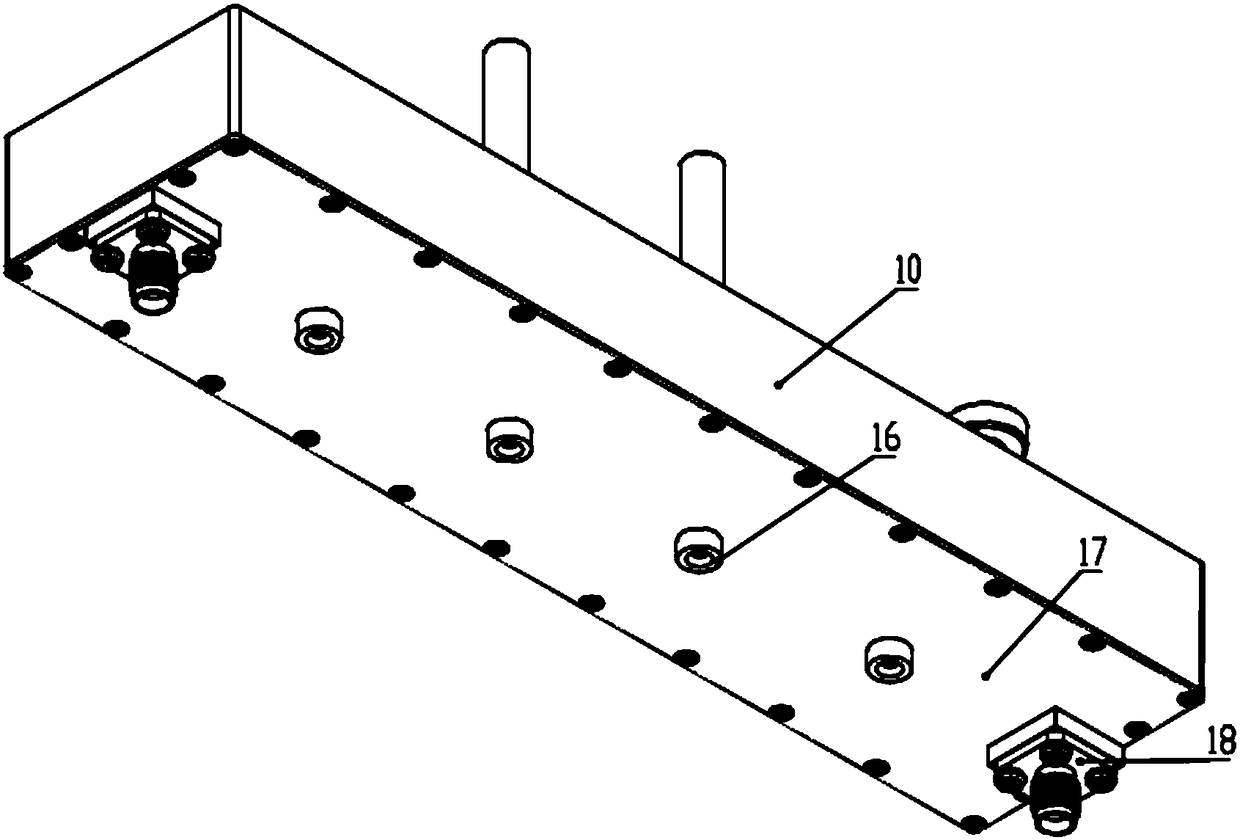

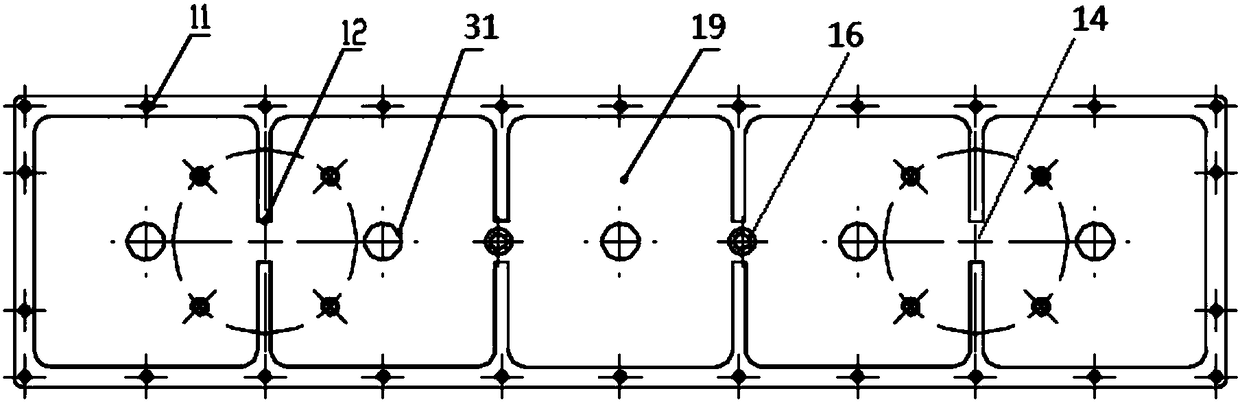

[0031] Embodiment 1, this embodiment is a C-band electronically adjustable cavity filter such as figure 1 As shown, it is mainly divided into three parts: 1) cavity filter; 2) frequency tuning structure 30; 3) motor 42 driving part. The cavity filter is a fifth-order structure in which five resonant cavities 19 resonate with each other. Five frequency tuning columns 31 are located at the center of each resonant cavity 19, and the operating frequency of the filter is adjusted by inserting depth. The tuning columns 31 are all fixed on the tuning bracket 35, and the up and down movement of the tuning bracket 35 is realized by the screw 50 of the stepping motor 42 and the transmission structure of the encrypted high-precision screw thread 304 on the tuning bracket 35, in order to ensure the horizontal position of the tuning bracket 35 Stable and motionless, two linear bearings 33 are set in the middle of the tuning bracket 35, so that the tuning bracket 35 can only move up and dow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com