Quickly cooled long-life conical rotor motor

A conical rotor, rapid cooling technology, used in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problem of heat difficulty, prolong the service life, enhance the heat dissipation effect, and ensure the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

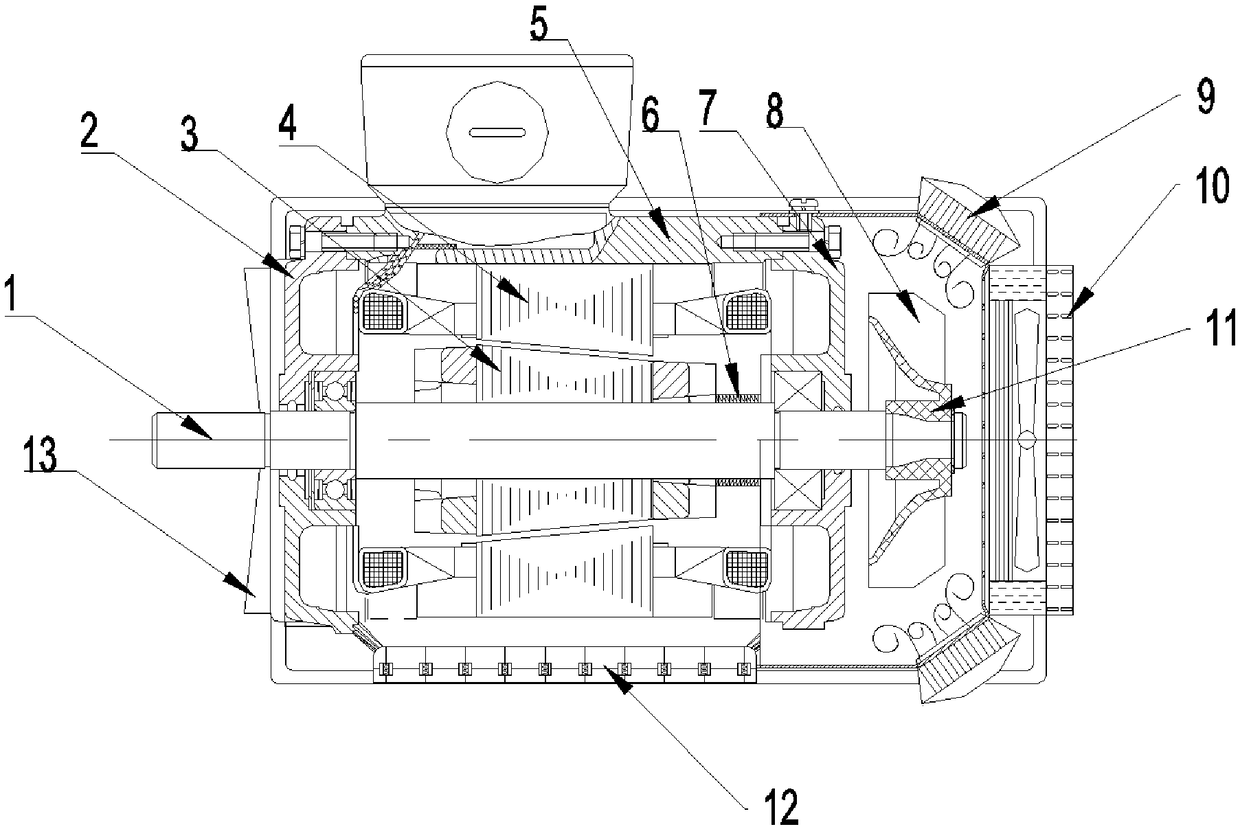

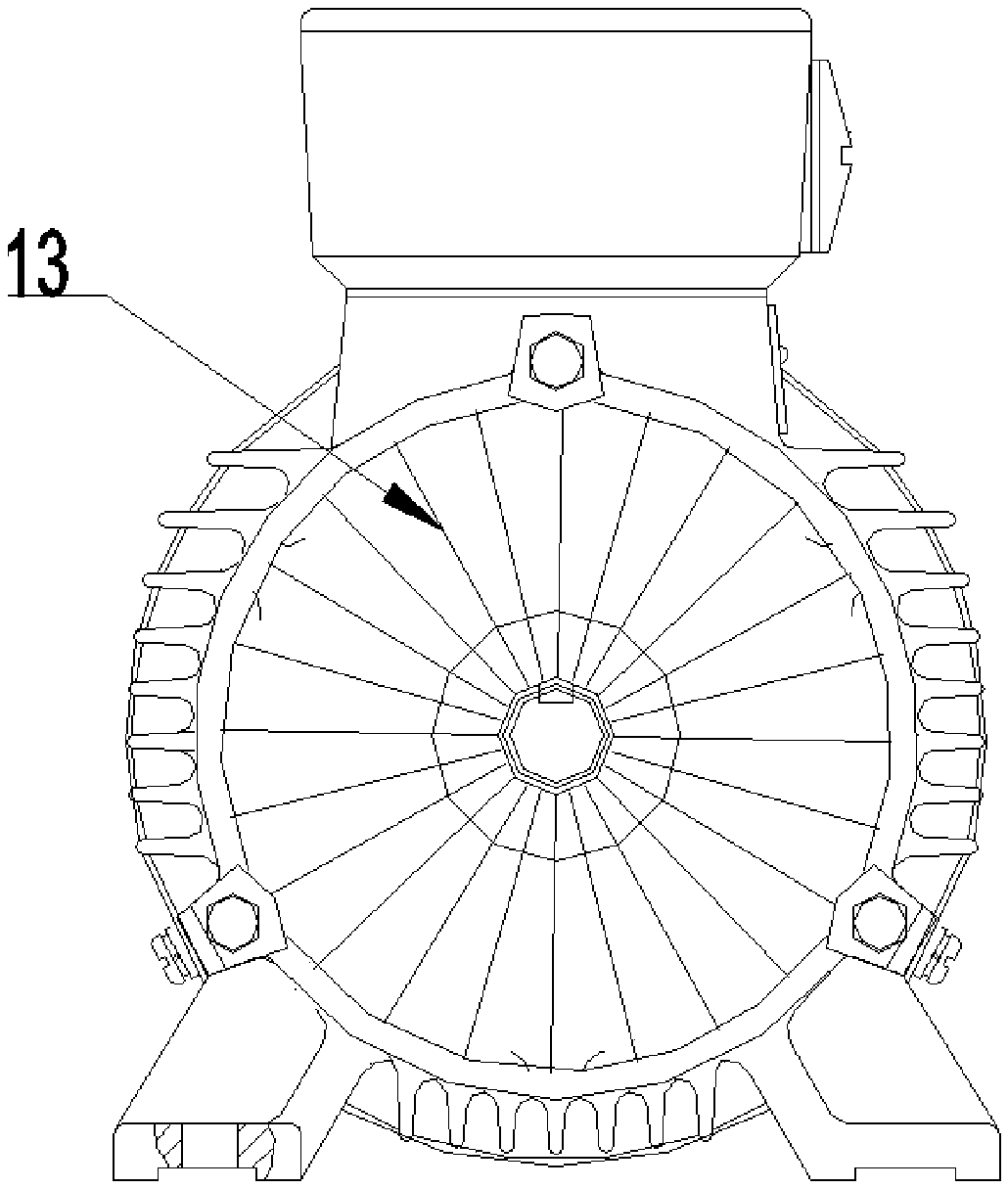

[0039] As a basic example:

[0040] A fast-cooling long-life conical rotor motor includes a housing 5 and a rotating shaft 1, the rotating shaft 1 is arranged inside the housing 5, the inner wall of the housing 5 is connected with a stator 4, and the inner cavity of the stator 4 is Conical, the rotor 3 is installed on the rotating shaft 1, the shape of the rotor 3 is conical, the front end of the rotating shaft 1 is equipped with a front end cover 2, it is characterized in that the rear end of the rotating shaft 1 is connected with a fan brake wheel 11, so The housing 5 around the fan brake wheel 11 is connected with a corner-end heat transfer head 9, and the rear end of the housing 5 is connected with a brake cooling device 10, and an exhaust blade 17 is installed in the braking cooling device 10. The brake cooling device 10 is also connected with a liquid cooling tube.

[0041] The outer wall of the housing 5 covered by the brake cooling device 10 is provided with a plurali...

Embodiment 2

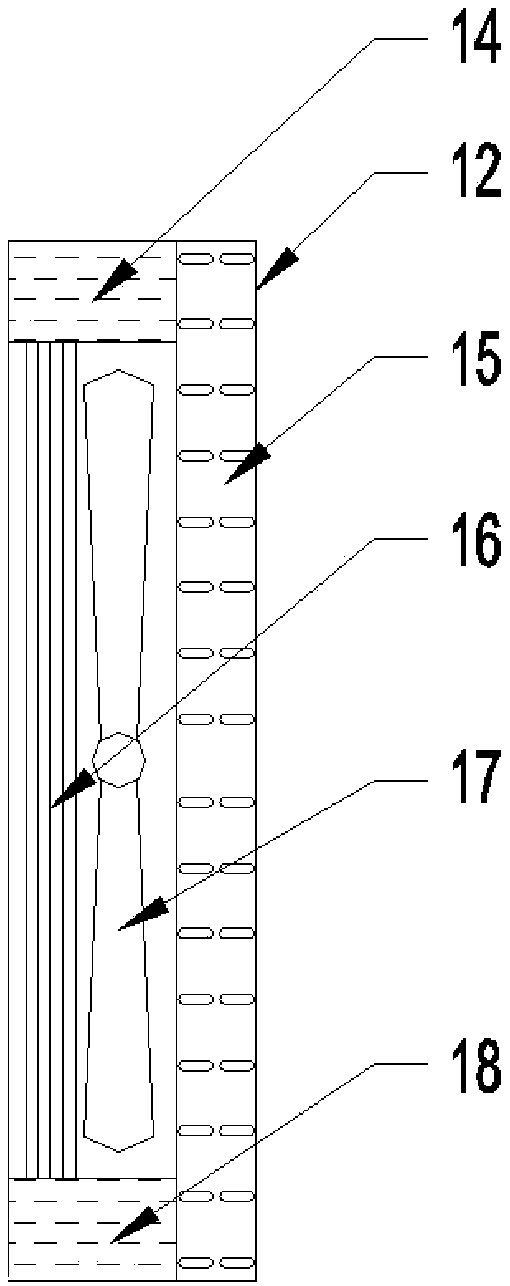

[0043]This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the interior of the brake cooling device 10 includes an upper liquid chamber 14 above and a lower liquid chamber below. chamber 18, and a fan blade 17 is installed between the upper liquid chamber 14 and the lower liquid chamber 18, and both the upper liquid chamber 14 and the lower liquid chamber 18 are connected with the liquid cooling pipe.

[0044] Further, a heat dissipation pipe 16 is connected between the upper liquid chamber 14 and the lower liquid chamber 18, and the heat dissipation pipe 16 is vertically arranged and attached to the housing 5, and the brake cooling device 10 is on the side away from the housing 5. A heat dissipation cover 15 is installed, and the exhaust blade 17 is installed between the heat dissipation pipe 16 and the heat dissipation cover 15, and the heat dissipation cover 15 is provided wi...

Embodiment 3

[0047] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the corner-end heat-conducting head 9 includes an arc-shaped heat-absorbing sheet 24 at the bottom, and the arc-shaped The heat absorbing sheet 24 is arranged around the fan brake wheel 11 in the housing 5, and the arc-shaped heat absorbing sheet 24 is connected with a thermal transition layer 22 on the inner wall of the housing 5, and a heat conducting sheet is connected above the thermal transition layer 22 23 , the heat conduction sheet 23 divides the inside of the corner-end heat conduction head 9 into a plurality of cavities, and the heat conduction cavity 21 is formed above the heat conduction sheet 23 .

[0048] The separated cavity can make the heat evenly distributed in it, so as to ensure that the heat conducting sheet 23 can quickly conduct heat with the largest effective area, and the arc-shaped heat absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com