Intelligent control metal cutting equipment

A metal cutting, intelligent control technology, applied in metal processing equipment, drilling/drilling equipment, manufacturing tools, etc., can solve the problems of single working mode and method, high work risk for operators, and it is difficult to avoid misoperation, etc. Achieve the effect of improving product accuracy, walking and moving flexibly, and fine-tuning flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

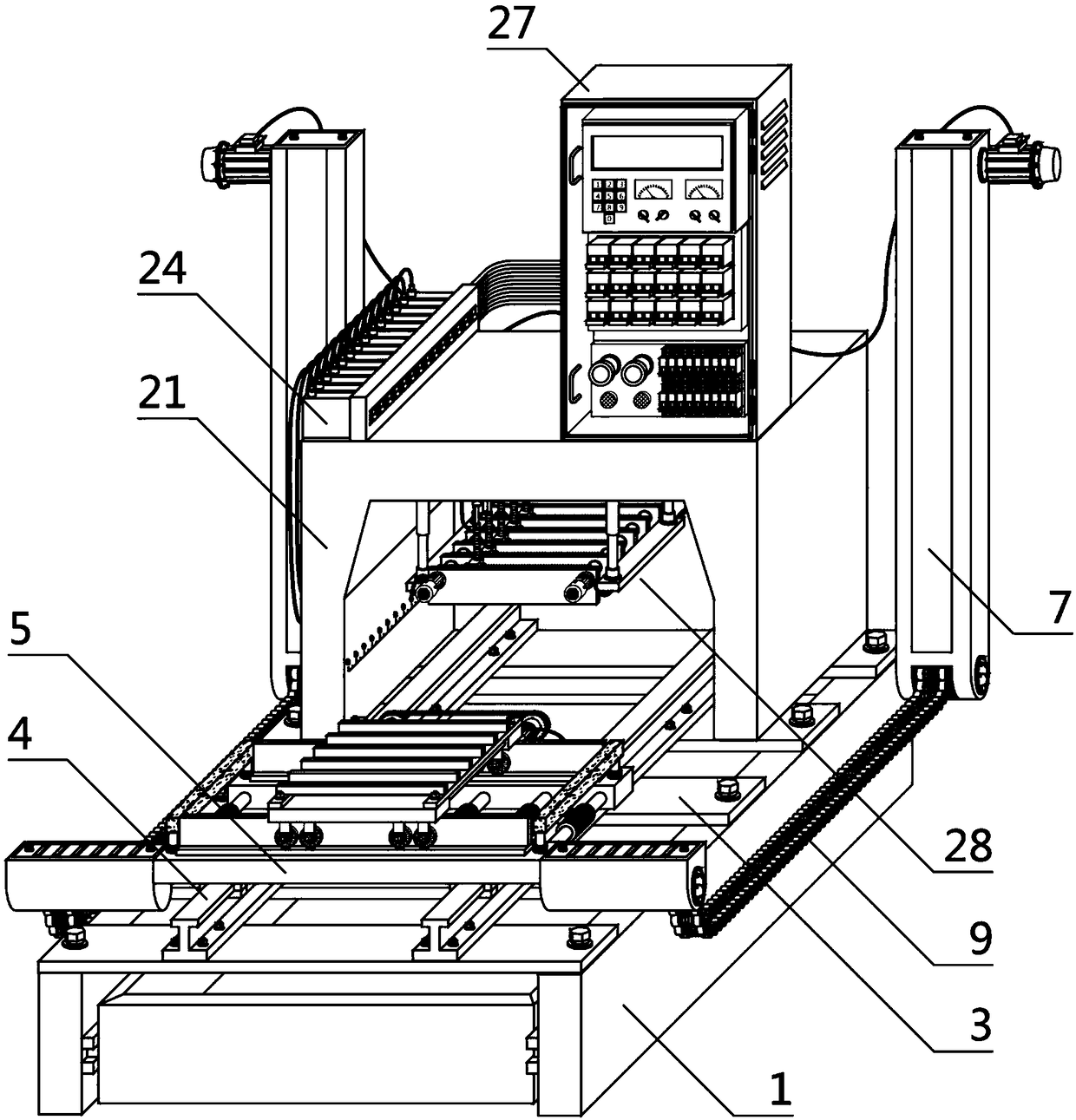

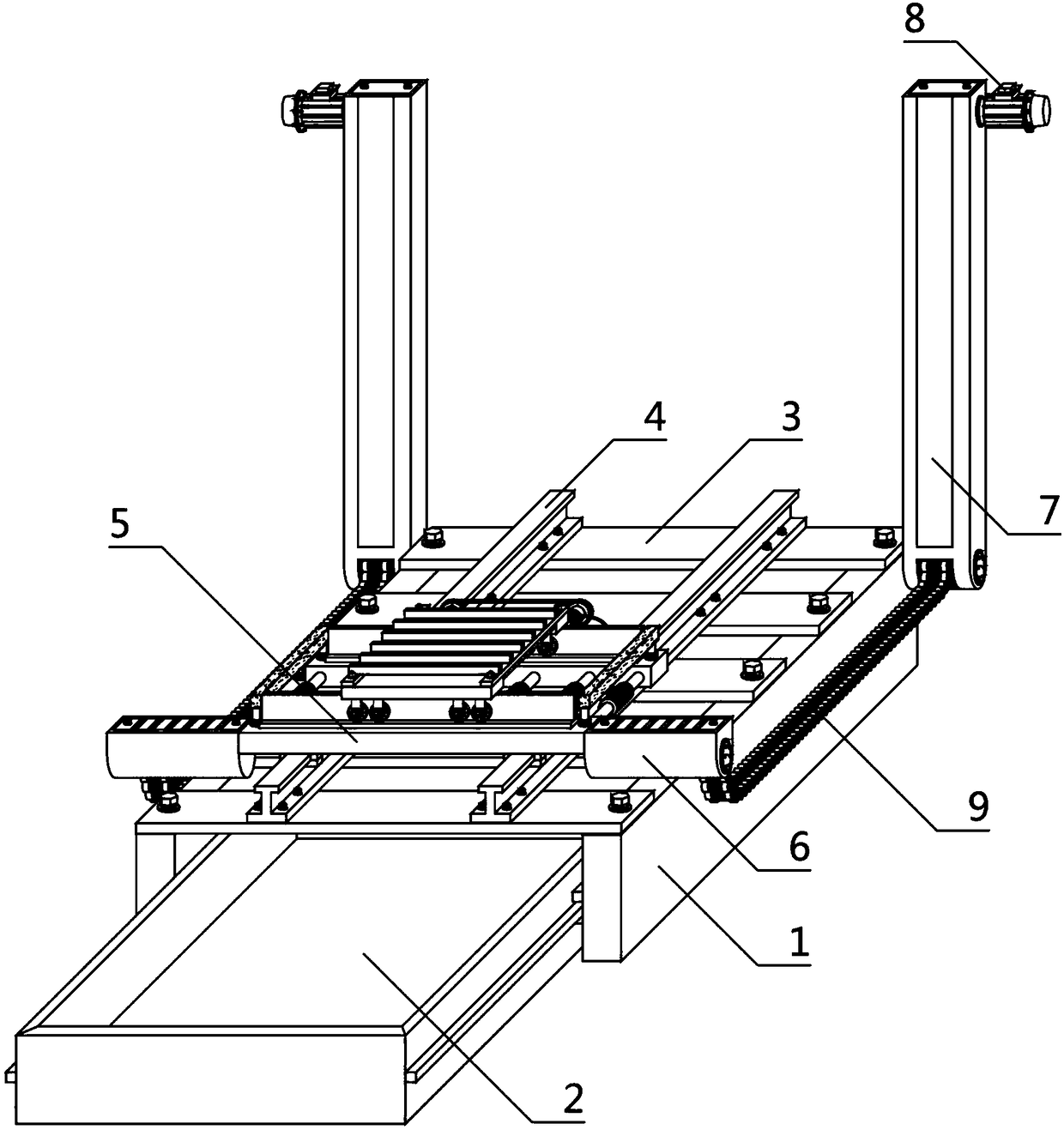

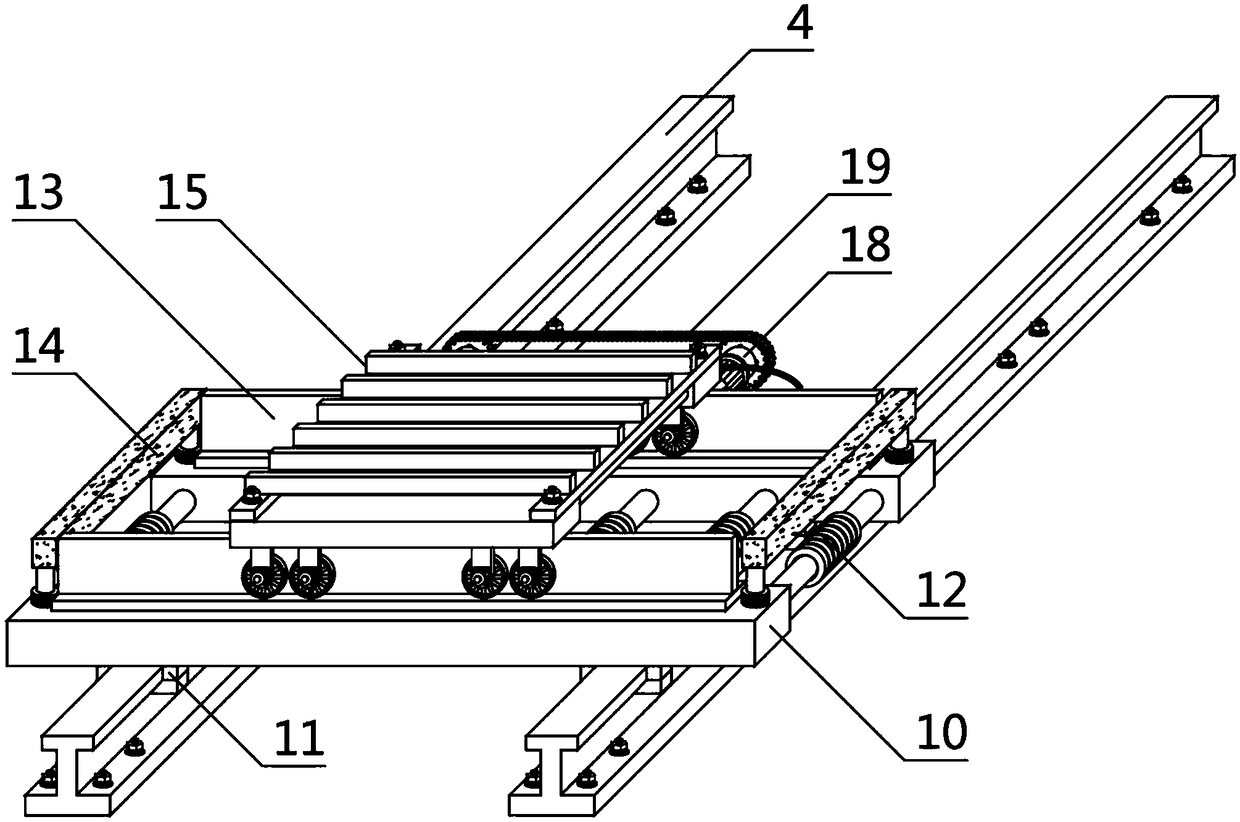

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 An intelligent control metal cutting equipment is shown, which is characterized in that: a base 1, several support plates 3, several cutting displacement rails 4, a cutting displacement device 5, several traction fixing frames 6, several traction boxes 7, cutting Carrying moving device 15, cutting operation cabin 21, signal receiver 24, control box 27 and pressing down cutting device 28, the base 1 is also provided with a waste material recovery box 2, and the waste material recovery box 2 is located inside the base 1 , the waste recycling box 2 is fixedly connected to the base 1, any of the support plates 3 is located on the top of the base 1, the support plate 3 is fixedly connected to the base 1, and any of the cutting displacement rails 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com