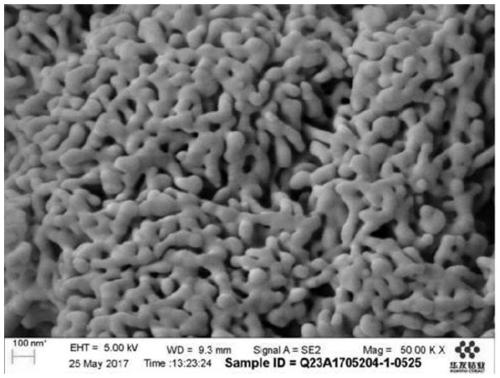

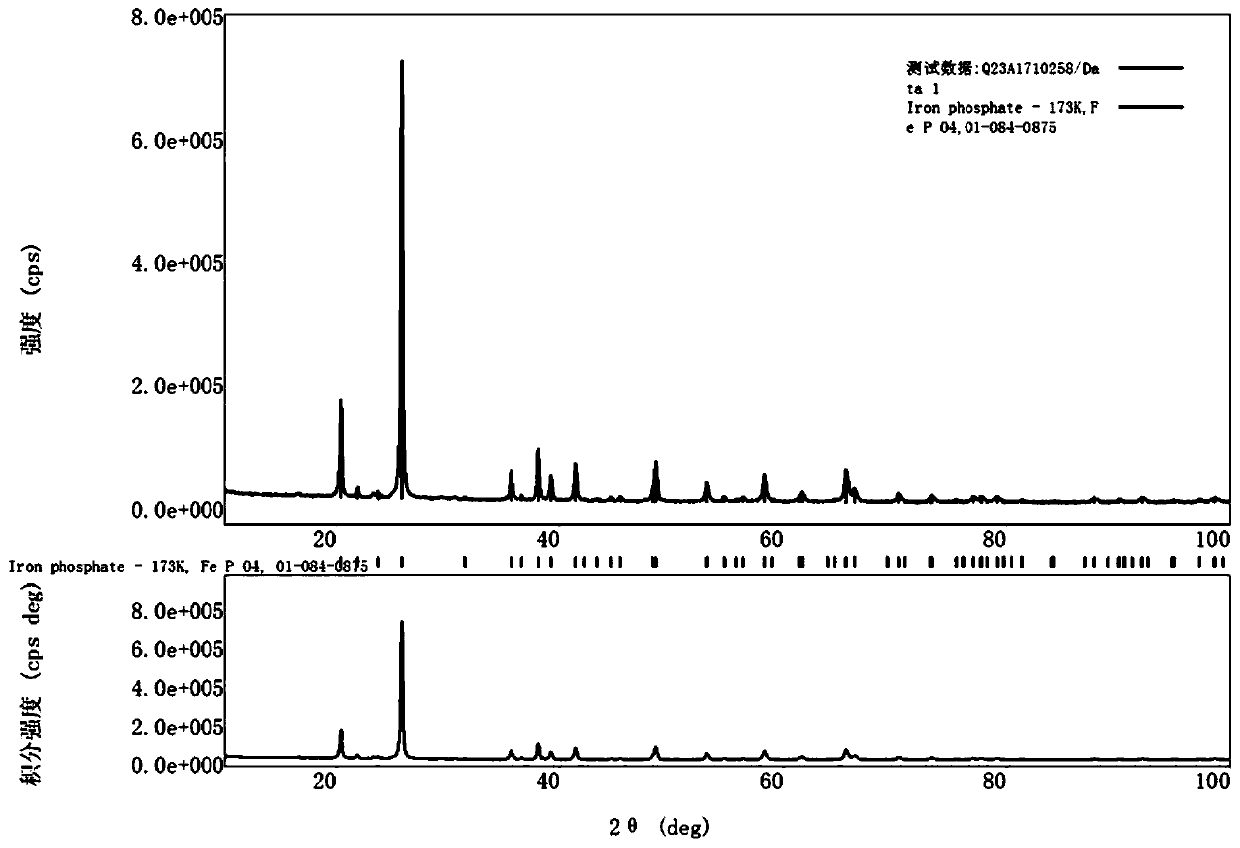

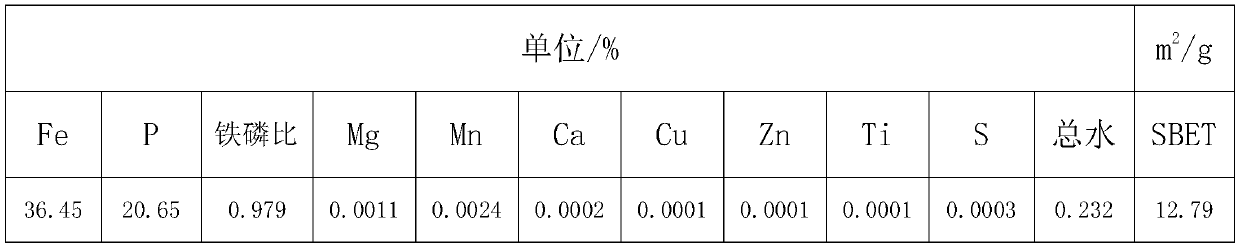

A method for preparing battery-grade iron phosphate with low impurity, high iron-phosphorus ratio and large specific surface area

A large specific surface area, iron phosphate technology, applied in nanotechnology, chemical instruments and methods, phosphorus compounds, etc. for materials and surface science, can solve problems such as unfavorable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Dissolve ferrous sulfate in pure water to prepare a ferrous sulfate solution with an iron ion concentration of 60g / L, add iron powder with 0.5% ferrous mass, raise the temperature to 60°C, keep it warm for 3 hours, and purify and remove Ti, Cu, and Al , Zn and other impurity ions, take the supernatant after standing, and filter to obtain the purified ferrous sulfate solution.

[0046] Inject 1000L pure water into 10m 3 The reaction kettle is used as the bottom liquid, and the temperature is raised to 30°C. Under stirring, the iron ion concentration is 60g / L ferrous sulfate solution, 120g / L diammonium hydrogen phosphate solution and 20% hydrogen peroxide are added into the reaction kettle at the same time for precipitation reaction. The flow rate of ferrous sulfate solution is 2000L / h, the flow rate of diammonium hydrogen phosphate solution is 3200L / h, the flow rate of hydrogen peroxide is 400L / h, the synthetic pH value is 2, and the feeding is stopped after 1 hour of re...

Embodiment 2

[0052] Dissolve ferrous sulfate in pure water to prepare a ferrous sulfate solution with an iron ion concentration of 100g / L, add iron powder with 1.2% ferrous mass, heat up to 80°C, keep it warm for 2 hours, and purify and remove Ti, Cu, and Al , Zn and other impurity ions, take the supernatant after standing, and filter to obtain the purified ferrous sulfate solution.

[0053] Inject 1000L pure water into 10m 3 The reaction kettle is used as the bottom liquid, and the temperature is raised to 40°C. Under stirring, the iron ion concentration of 100g / L ferrous sulfate solution, 160g / L ammonium dihydrogen phosphate solution and 20% hydrogen peroxide are added to the reaction kettle at the same time to cause precipitation reaction. The flow rate of ferrous sulfate solution is 1000L / h, the flow rate of ammonium dihydrogen phosphate solution is 1400L / h, the flow rate of hydrogen peroxide is 430L / h, the synthetic pH value is 2.5, and the feeding is stopped after 2 hours of reaction...

Embodiment 3

[0059] Dissolve ferrous sulfate in pure water to prepare a ferrous sulfate solution with an iron ion concentration of 120g / L, add iron powder with 2% ferrous mass, heat up to 99°C, keep it warm for 1 hour, and purify and remove Ti, Cu, and Al , Zn and other impurity ions, take the supernatant after standing, and filter to obtain the purified ferrous sulfate solution.

[0060] Inject 1000L pure water into 10m 3 The reaction kettle is used as the bottom liquid, and the temperature is raised to 50°C. Under stirring, the concentration of 120g / L ferrous sulfate solution, 200g / L diammonium hydrogen phosphate solution and 20% hydrogen peroxide are added to the reaction kettle at the same time for precipitation reaction. The flow rate of iron solution is 1600L / h, the flow rate of diammonium hydrogen phosphate solution is 2800L / h, the flow rate of hydrogen peroxide is 510L / h, the synthetic pH value is 3, and the feeding is stopped after 1.5h of reaction. Stirring was continued for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com