Er-contained quasi-crystal reinforced magnesium-lithium alloy and preparation method thereof

A magnesium-lithium alloy and quasi-crystal technology, applied in the field of metal structural materials, achieves the effect of small segregation of Zr element, strong resistance to decay, and high yield of Zr element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

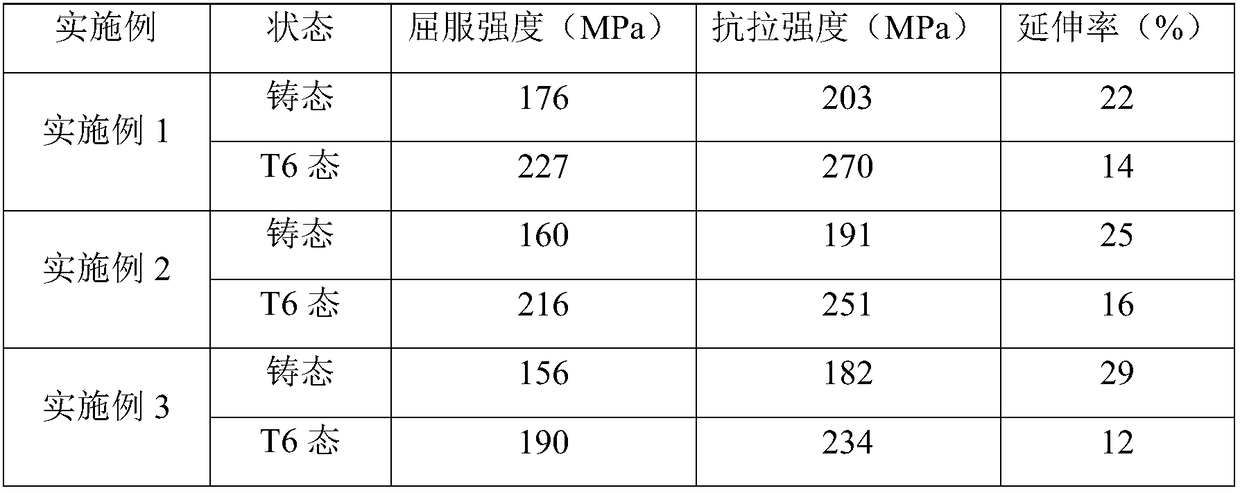

Embodiment 1

[0023] This embodiment relates to a quasicrystal strengthened magnesium-lithium alloy containing Er. The Mg-Li-Zn-Er-Zr magnesium-lithium alloy contains the following components in mass percentage: Li 10%, Zn 0.5%, Er 0.2 %, Zr 0.3%, the total amount is less than 0.02wt.% by mass percentage of Si, Fe, Cu and Ni and other unavoidable impurities, and the balance is Mg. Wherein, the mass ratio of Zn and Er is 2.5:1, and Zr is represented by ZrCl 4 Mixed salt is 72% ZrCl 4 -12%LiCl-4%LiF-12%CaF 2 (mass percentage) added.

[0024] This embodiment also relates to a method for preparing the aforementioned Mg-Li-Zn-Er-Zr magnesium-lithium alloy: the method includes two stages of smelting and heat treatment.

[0025] Wherein, the smelting process includes the following steps: melting each component of the alloy according to the ratio and then raising the temperature to 720° C., mechanically stirring for 2 minutes, standing for 3 minutes for heat preservation, and then casting.

[0...

Embodiment 2

[0029] This embodiment relates to a quasicrystal strengthened magnesium-lithium alloy containing Er. The Mg-Li-Zn-Er-Zr magnesium-lithium alloy contains the following components in mass percentage: Li 13%, Zn 6%, Er 3 %, Zr 0.1%, the total amount is less than 0.02wt.% by mass percentage of inevitable impurities such as Si, Fe, Cu and Ni, and the balance is Mg. Wherein, the mass ratio of Zn and Er is 2:1, Zr is ZrCl 4 Mixed salt is 65% ZrCl 4 -15%LiCl-5%LiF-15%CaF 2 (mass percentage) added.

[0030] This embodiment also relates to a method for preparing the aforementioned Mg-Li-Zn-Er-Zr magnesium-lithium alloy: the method includes two stages of smelting and heat treatment.

[0031] Among them, the smelting process includes the following steps: melting each component of the alloy according to the ratio and then heating up to 690°C, mechanically stirring for 5 minutes, standing for 9 minutes for heat preservation, and then casting.

[0032] Heat treatment process: the as-cast...

Embodiment 3

[0035] This embodiment relates to a quasicrystal strengthened magnesium-lithium alloy containing Er. The Mg-Li-Zn-Er-Zr magnesium-lithium alloy contains the following components in mass percentage: Li 16%, Zn 4%, Er 4 %, Zr 0.6%, the total amount is less than 0.02wt.% by mass percentage of inevitable impurities such as Si, Fe, Cu and Ni, and the balance is Mg. Among them, the mass ratio of Er and Zn is 1:1, Zr is ZrCl 4 Mixed salt is 79% ZrCl 4 -9%LiCl-3%LiF-9%CaF 2 (mass percentage) added.

[0036] This embodiment also relates to a method for preparing the aforementioned Mg-Li-Zn-Er-Zr magnesium-lithium alloy: the method includes two stages of smelting and heat treatment.

[0037] Wherein, the smelting process includes the following steps: melting each component of the alloy according to the ratio and then raising the temperature to 660° C., mechanically stirring for 8 minutes, standing for 15 minutes for heat preservation, and then casting.

[0038] Heat treatment proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com