A soft-hard composite nano-multilayer coating tool and its preparation method

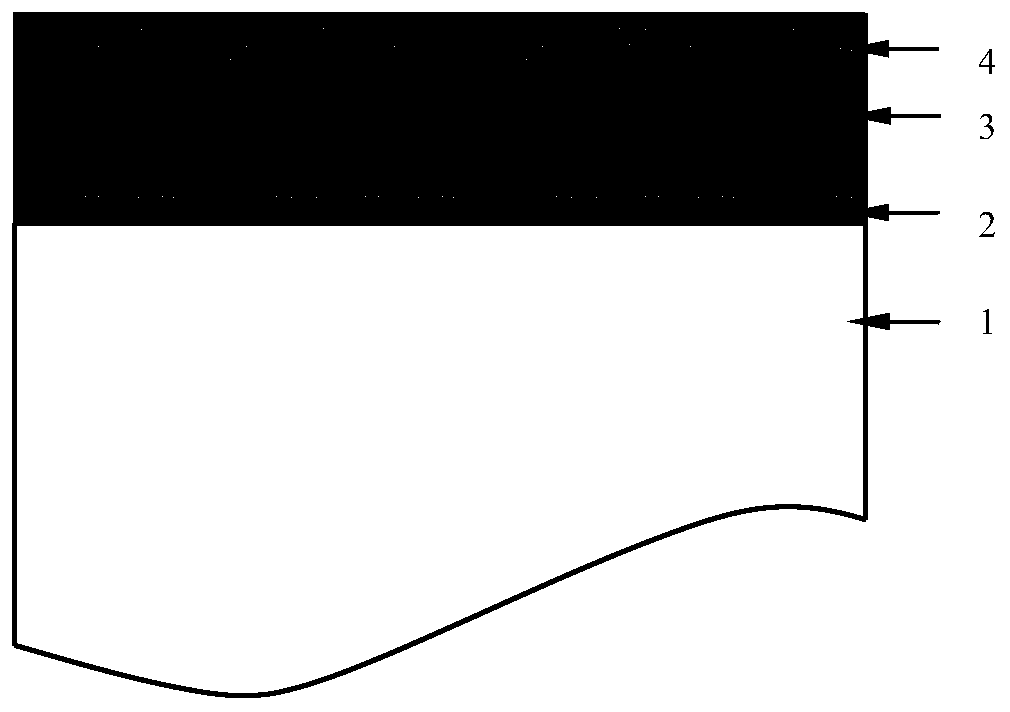

A soft-hard composite and nano-multilayer technology, which is applied in coating, metal material coating process, superimposed layer plating, etc., can solve the problems affecting the surface quality of the processed workpiece, coating peeling, friction coefficient increase, etc. Achieve the effects of reducing residual thermal stress, improving coating hardness, and enhancing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The steps of the preparation method of Example 1 are as follows:

[0032] (1) Pre-treatment: The cemented carbide substrate is mirror-polished, put in acetone solution for ultrasonic cleaning for 15 minutes, and then put into alcohol solution for ultrasonic cleaning for 15 minutes, dried by nitrogen, and placed in the vacuum chamber of the coating machine. This process is forbidden to touch Touch the surface of the substrate, and the vacuum chamber is evacuated to 3.0×10 -4 Pa, heat to 350°C, hold for 30 minutes.

[0033] (2) Glow cleaning: Enter Ar gas, working pressure 1.5Pa, and perform glow discharge cleaning for 20 minutes to remove tiny attached impurities on the surface of the substrate.

[0034] (3) Deposition of Zr: Using DC magnetron sputtering technology, a pure Zr target is selected and placed on the DC target source, high-purity Ar gas is introduced, the Ar flow is 70 sccm, the deposition pressure is 0.5 Pa, the deposition power is 200 W, and the deposition thickn...

Embodiment 2

[0038] The steps of the preparation method of Example 2 are as follows:

[0039] (1) Pre-treatment: The cemented carbide substrate is mirror-polished, put in acetone solution for ultrasonic cleaning for 15 minutes, and then put into alcohol solution for ultrasonic cleaning for 15 minutes, dried by nitrogen, and placed in the vacuum chamber of the coating machine. This process is forbidden to touch Touch the surface of the substrate, and the vacuum chamber is evacuated to 3.0×10 -4 Pa, heat to 350°C, hold for 30 minutes.

[0040] (2) Glow cleaning: Enter Ar gas, working pressure 1.5Pa, and perform glow discharge cleaning for 20 minutes to remove tiny attached impurities on the surface of the substrate.

[0041] (3) Deposition of Zr: Using DC magnetron sputtering technology, a pure Zr target is selected and placed on the DC target source, high-purity Ar gas is introduced, the Ar flow is 70 sccm, the deposition pressure is 0.5 Pa, the deposition power is 200 W, and the deposition thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com