A Track Line Coordinate Measuring System

A coordinate measurement system and line marking technology, applied to roads, tracks, measuring instruments, etc., can solve the problems of wasting manpower, time, and low measurement accuracy, and achieve the effects of reducing labor intensity, reducing operators, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

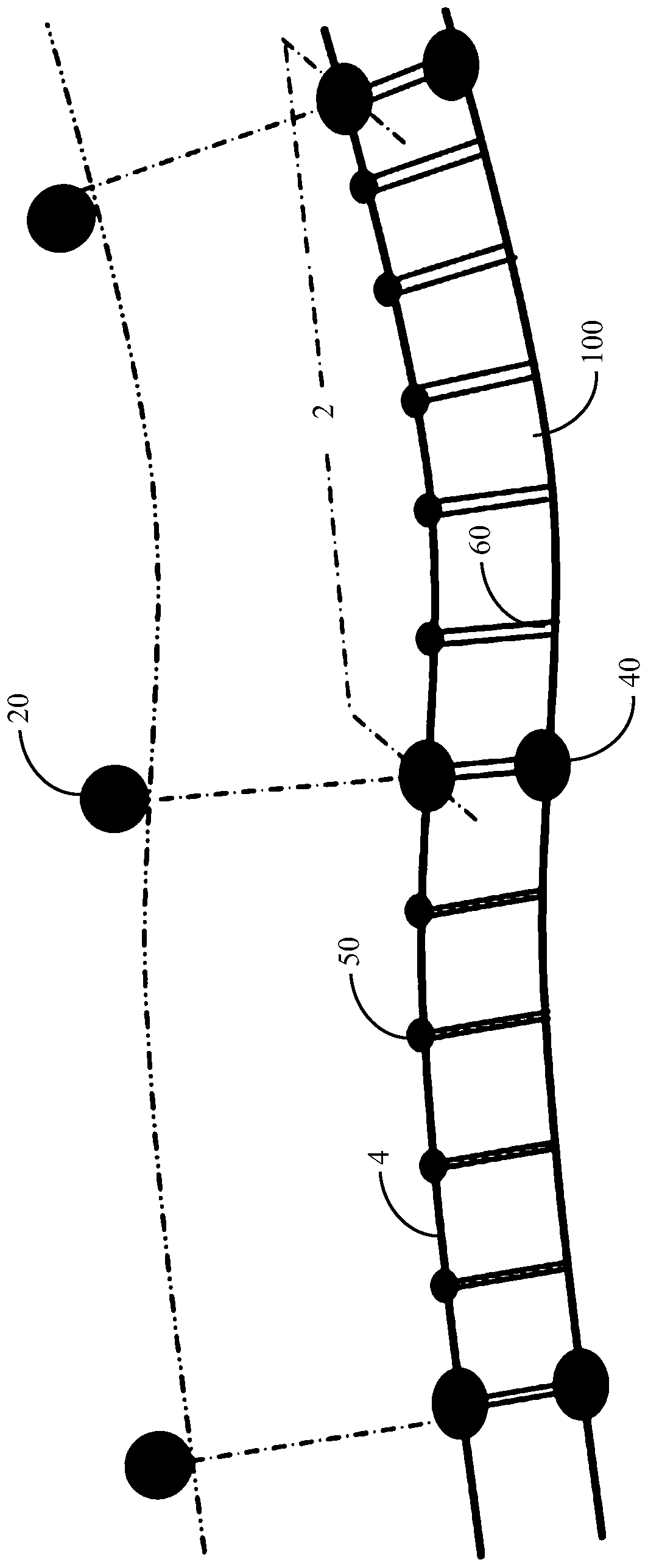

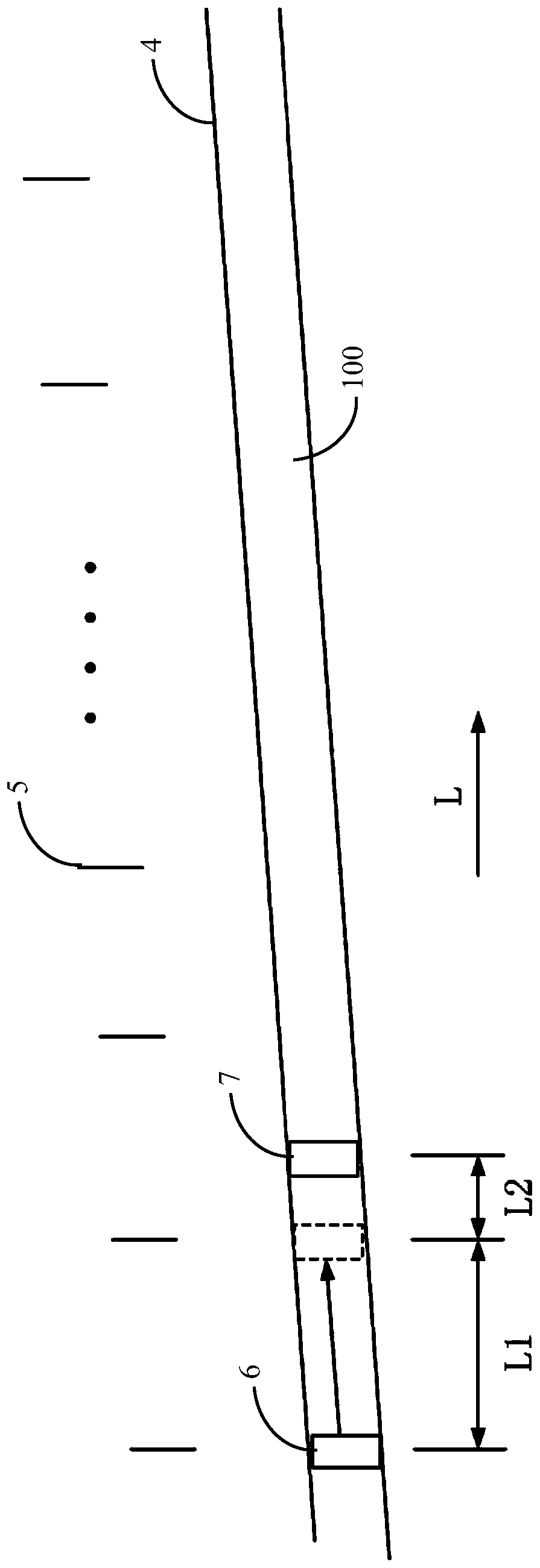

[0041] as attached Figure 5 And attached Figure 7 Shown, a kind of embodiment of track line coordinate measuring system of the present invention, specifically comprises:

[0042] The total station 1 is erected on the track line 100 for measuring the three-dimensional coordinates of CPⅢ point 20; as a preferred embodiment of the present invention, the total station 1 is set up between two rails 4 of the track line 100 The centerline position of the total station 1 can also be erected at a position other than the centerline of the two rails 4;

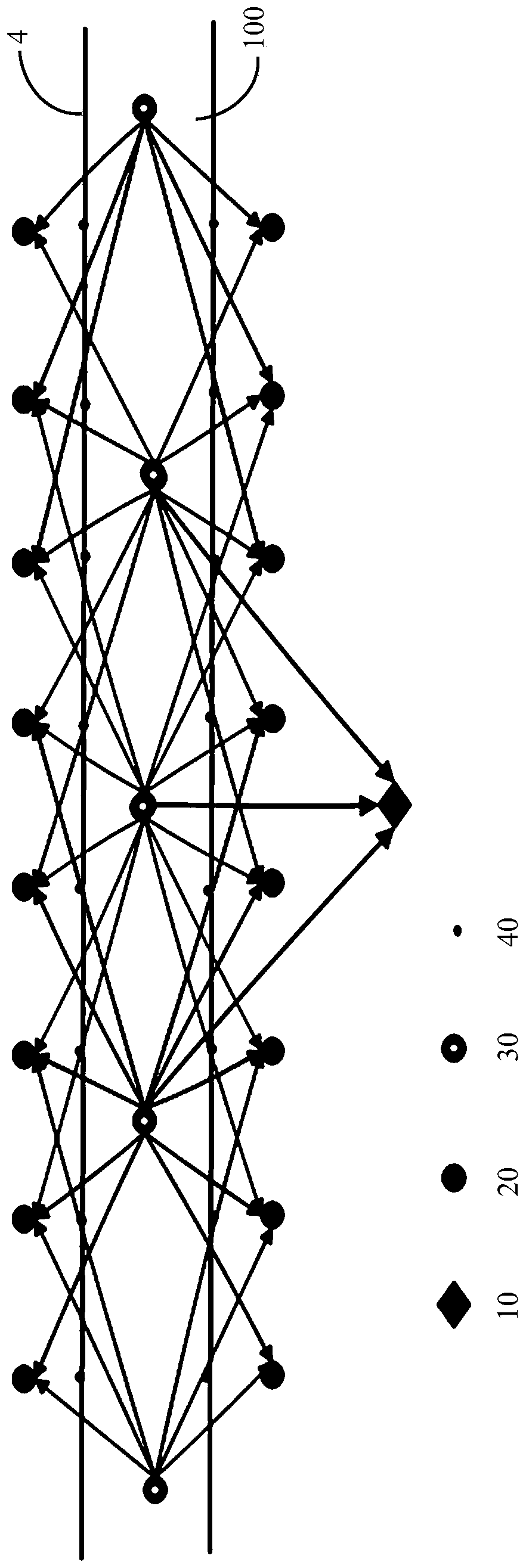

[0043] Rail inspection car 2, walks on track line 100, is used for measuring two line marking points 40 corresponding to two CPⅢ points 20 on track line 100 (in this embodiment, two lines corresponding to two CPⅢ points 20 on rail 4 The line shape between the marked points 40), and the horizontal distance and height difference between the two line marked points 40 and the corresponding two CPIII points 20;

[0044] And the processin...

Embodiment 2

[0054] as attached Figure 5 As shown, an embodiment of a method for measuring track line coordinates based on the device described in Embodiment 1, specifically comprises the following steps:

[0055] A) Network construction measurement process: measure the three-dimensional coordinates of CPⅢ point 20 by erecting a total station 1 on the track line 100, and measure the correspondence of two CPⅢ points 20 on the track line 100 by the rail inspection vehicle 2 running on the track line 100 The linear shape between the two line marking points 40, and the horizontal distance, height difference and vector distance between the two line marking points 40 and the corresponding two CPⅢ points 20; as a preferred embodiment of the present invention, the The total station 1 is erected at the center line position between the two rails 4 of the track line 100, and the total station 1 can also be erected at a position other than the center line of the two rails 4;

[0056] B) Coordinate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com