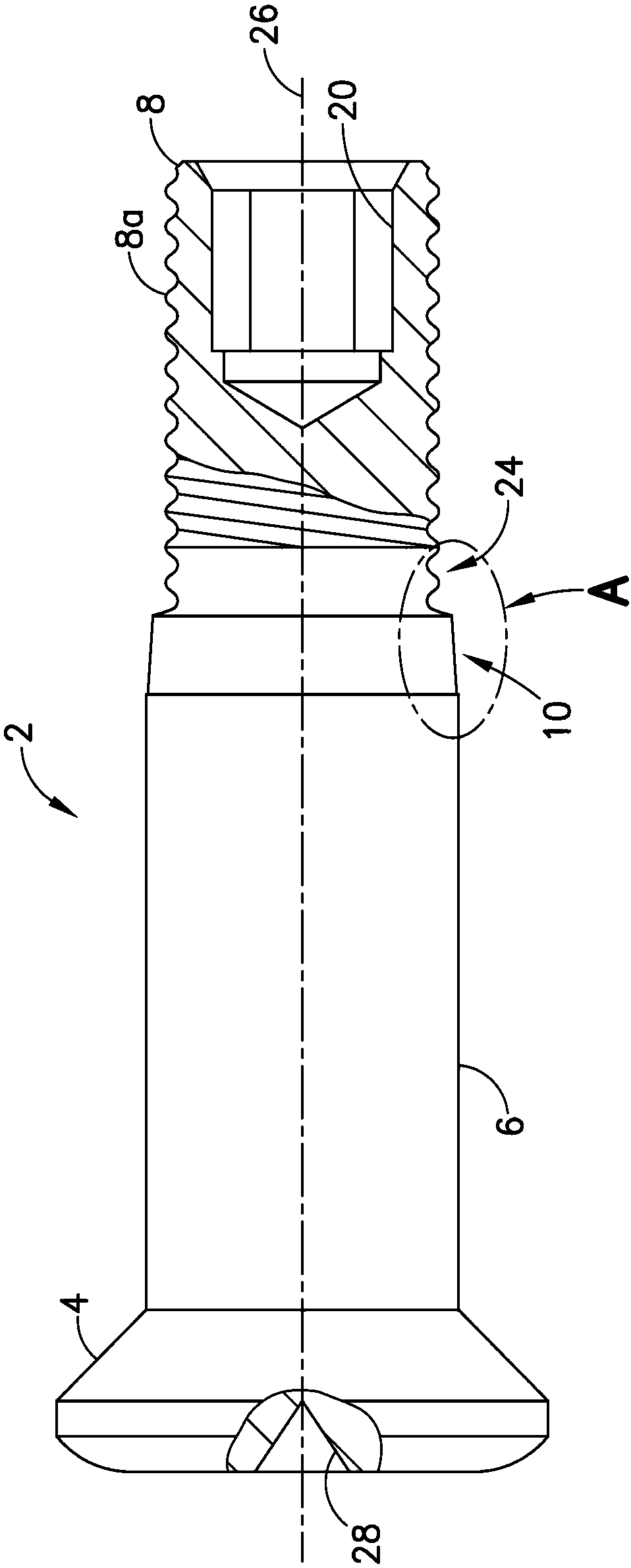

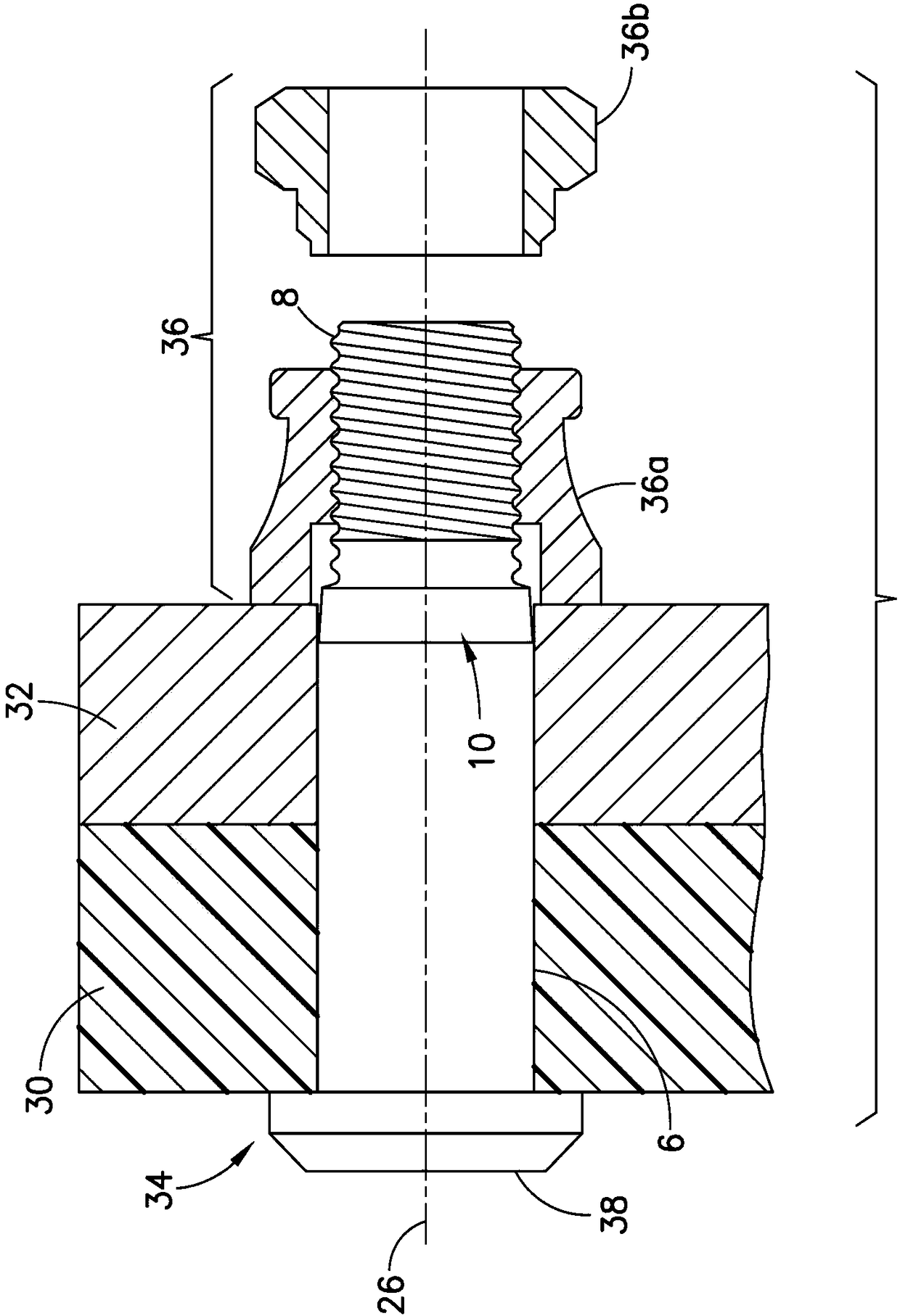

Radiused lead-in for interference fit fasteners

A technology of fasteners and rounded corners, which is applied in the direction of threaded fasteners, connecting components, and specially improved connectors for tensile loads, which can solve problems such as excessive layering, complicated installation methods of parts, and increased assembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] Clause 1. A fastener comprising: a head; a shank extending from the head, the shank comprising a cylindrical outer surface; a mating portion comprising an external protrusion; and a shank disposed on the a transition between the stem portion and the mating portion, wherein the transition portion includes a first radiused lead-in segment meeting the stem portion at a stem / lead-in intersection and a first radiused lead-in segments meet a second radiused lead-in segment that is gradually curved in a first axial direction towards the mating portion and has a first profile that is a circle with a first radius arc, and the second radiused lead-in section is sharply curved in the first axial direction and has a second profile that is an arc of a circle with a second radius smaller than the first radius.

[0041] Clause 2. The fastener of clause 1, wherein the first profile is the profile of an outer surface of the first radiused lead-in in a plane that intersects a central axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com