Portable in-situ multi-field coupling loading device for neutron scattering

A loading device, neutron scattering technology, applied in material analysis using radiation diffraction, material analysis using wave/particle radiation, measuring device, etc. problem, to achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

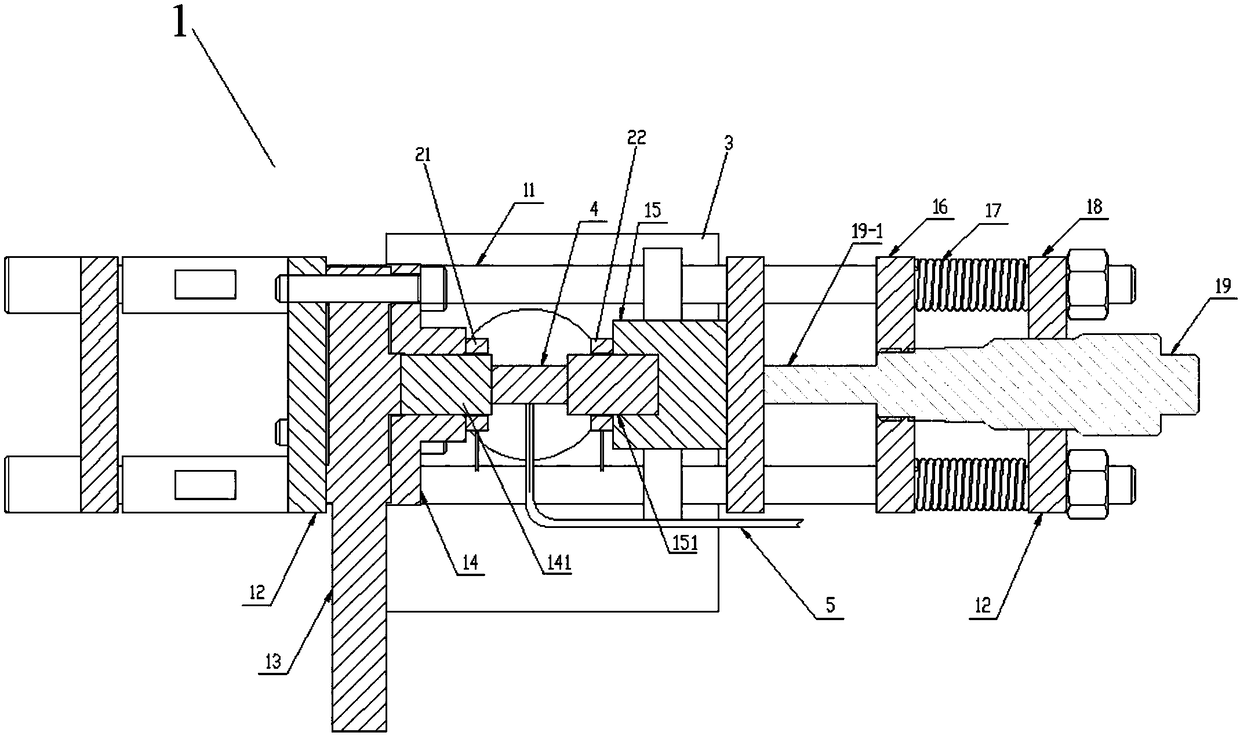

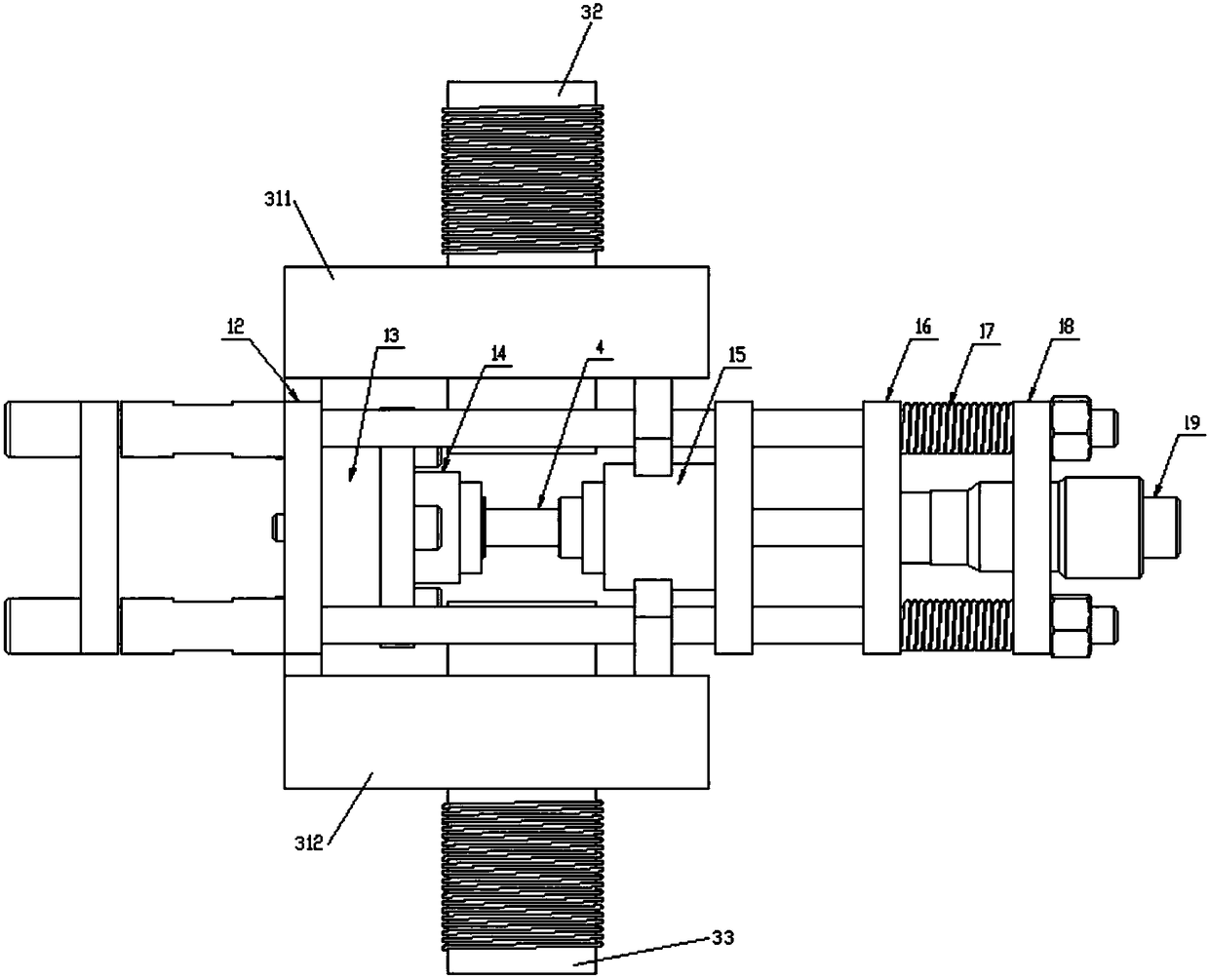

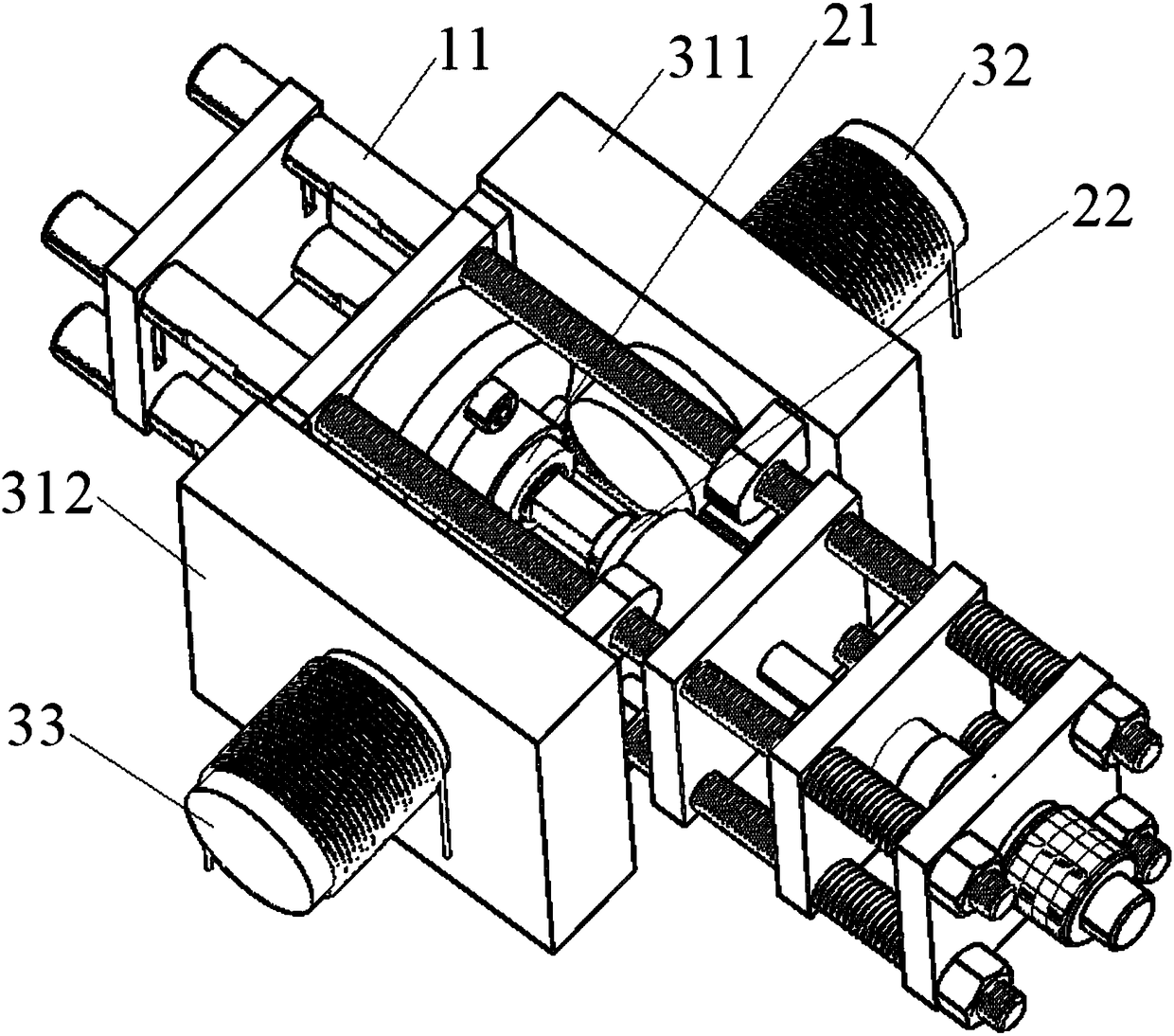

[0039] This example is a portable in-situ multi-field coupling loading device for neutron scattering, including a stress loading and testing component 1, a temperature loading component 2 and a magnetic field loading component 3.

[0040] Such as Figure 1 to Figure 3 As shown, the stress loading and testing assembly 1 includes two parallel guide rod groups 11, each guide rod group includes two guide rods, a total of four guide rods, and the four guide rods are used to support the stress loading and testing assembly 1 respectively. The four corners of the components play a supporting role; on the two parallel guide rod groups 11, the first fixed plate 12, the force sensor 13, the left clamp 14, and the right clamp corresponding to the left clamp 14 are sequentially installed Fixture 15, spring movable plate 16, spring group 17, second fixed plate 18 and stress loader 19; Wherein, first fixed plate 12, force sensor 13 and second fixed plate 18 are fixedly installed on the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com