An erp system for a concrete mixing plant

An ERP system, concrete technology, applied in the field of ERP system, can solve the problems of data loss, inconvenience of concrete mixing plant, data error and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention are further described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following.

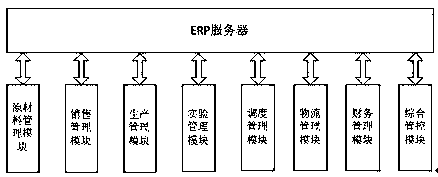

[0023] like figure 1 As shown, an ERP system for a concrete batching plant includes:

[0024] The ERP server is used to summarize the work progress information or work reports uploaded by each module in the ERP system, and provide a data exchange platform for each module of the ERP system;

[0025] The raw material management module is used to summarize the raw material information uploaded by the monitoring equipment of each raw material warehouse, determine whether the raw materials are sufficient, and when the raw material inventory is insufficient, generate a purchase order and submit it to the ERP server, and send it to the supplier server through the ERP server for raw material procurement;

[0026] The sales management module is used for the sales s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com