Process of forming semiconductor apparatus mounting on substrate

一种安装基板、半导体的技术,应用在半导体器件、半导体/固态器件制造、半导体/固态器件零部件等方向,能够解决半导体芯片与组装基板结合强度降低、小浸润性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Next, embodiments of the present invention will be described with reference to the drawings. In the description of the embodiments, reference numerals or symbols identical to or similar to each other will refer to elements identical to or similar to each other, and explanations will not be repeated.

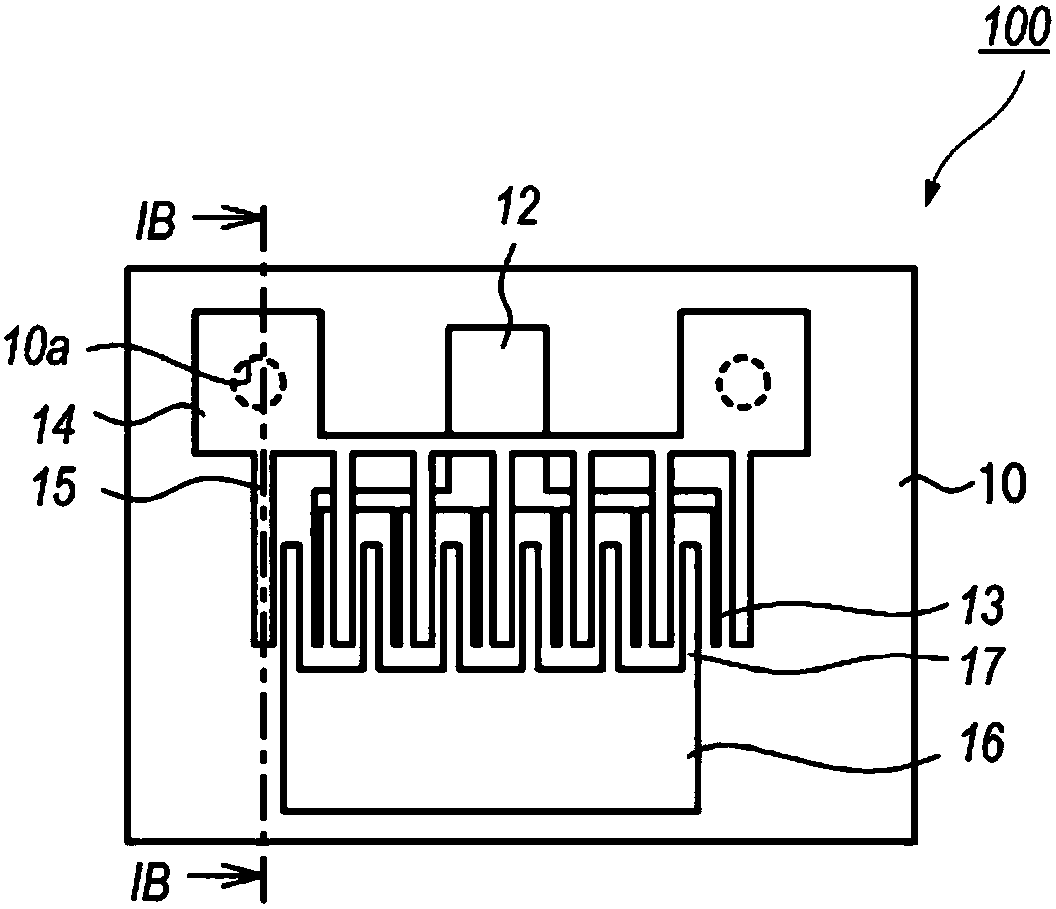

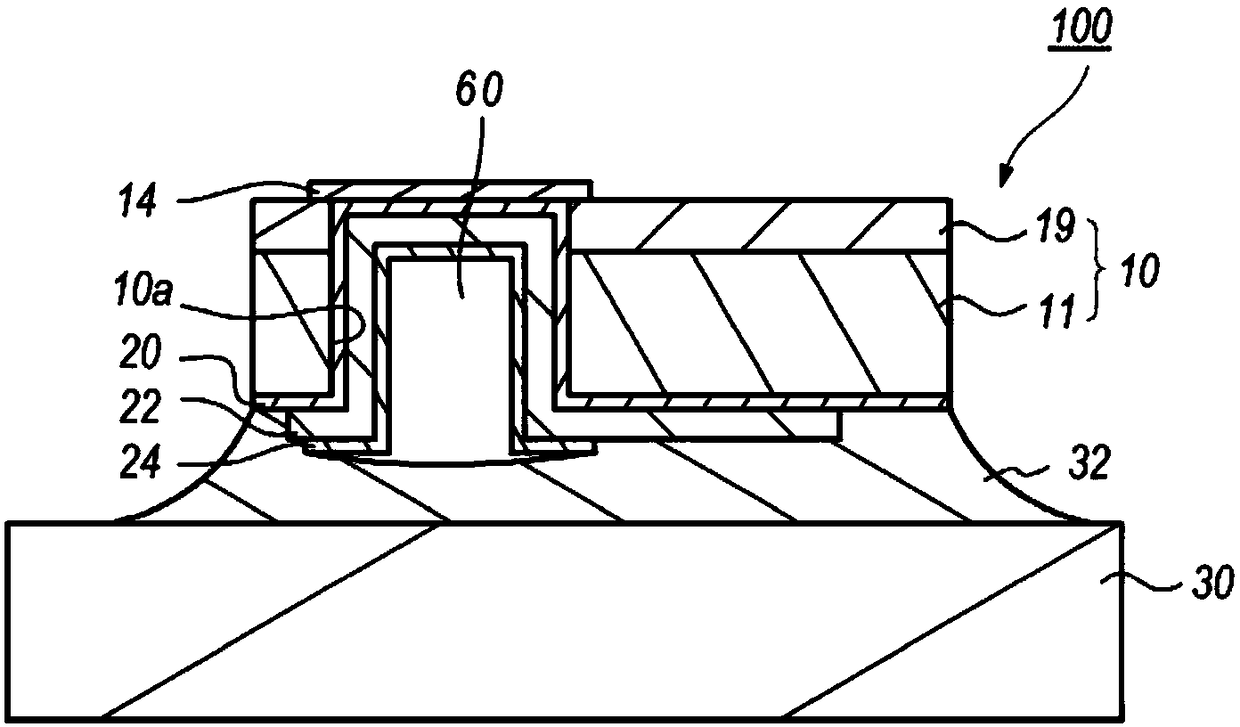

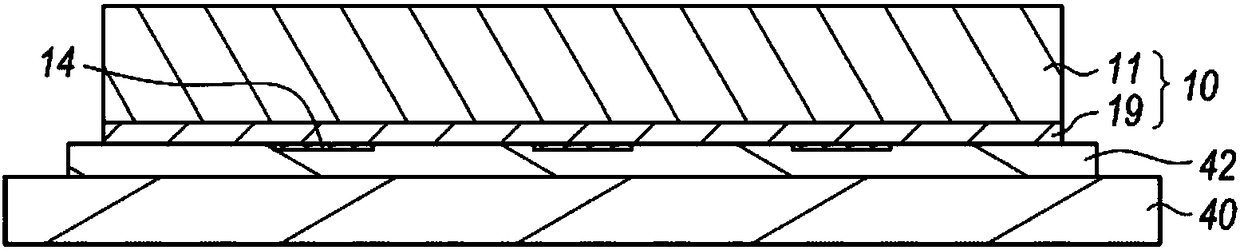

[0015] Figure 1A A plan view of a semiconductor device 100 according to a first embodiment of the present invention is shown. The semiconductor device 100 is a field effect transistor (FET) type, and the semiconductor device 100 includes a substrate 10, a gate pad 12, a gate finger (gatefinger) 13, a source pad 14, a source finger 15, a drain pad 16 and the drain finger 17. The epitaxial substrate 10 may include an insulating substrate 11 made of silicon carbide (SiC) and an epitaxial layer 19 grown on the insulating substrate 11 . The epitaxial layer 19 includes a channel layer made of gallium nitride (GaN) (the channel layer is sometimes called a carrier transport lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com