Double-layer piezoelectric ceramic electroacoustic component and preparation method thereof

A piezoelectric ceramic and electro-acoustic element technology, applied in the field of double-layer piezoelectric ceramic electro-acoustic element and its preparation, can solve the problems of easy breakage, limited application structure design, weakened electromechanical conversion efficiency, etc. The effect of improving the electro-acoustic conversion efficiency and increasing the thickness of the ceramic sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

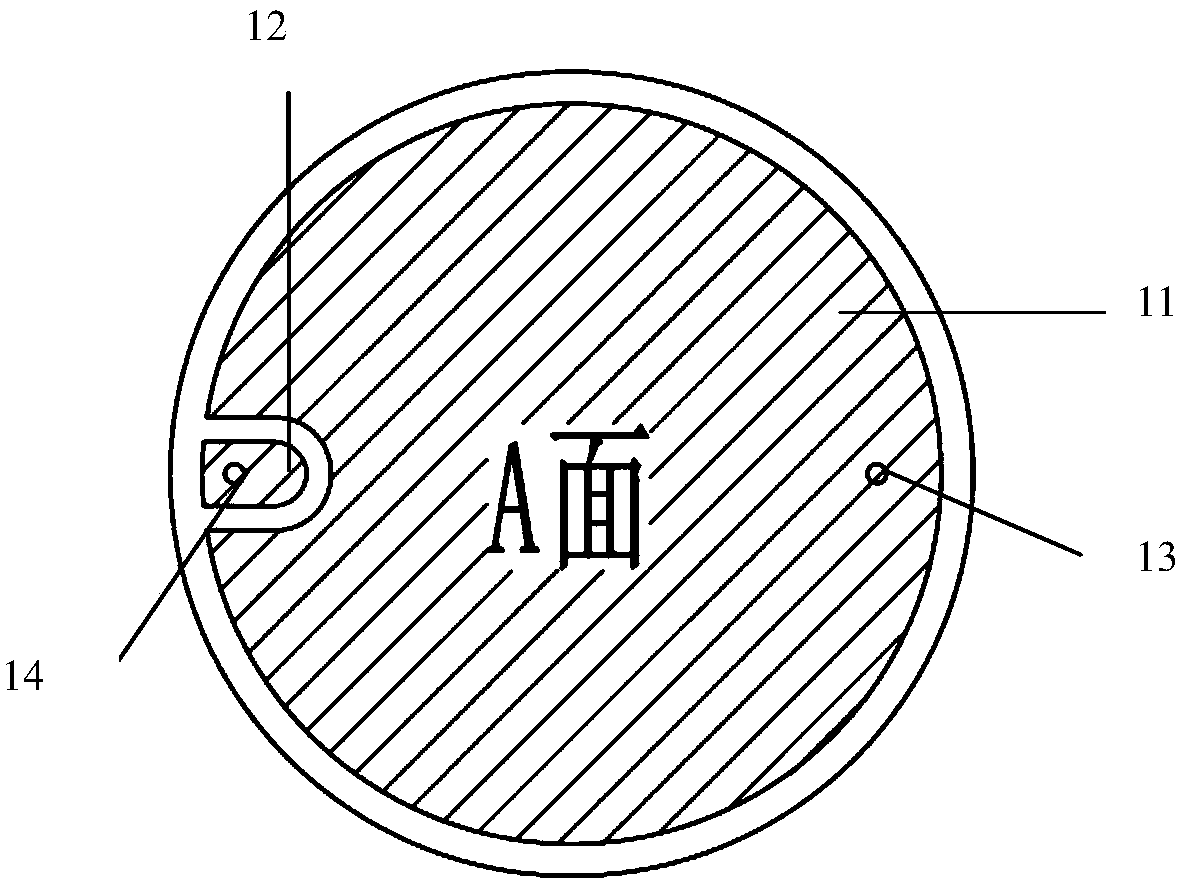

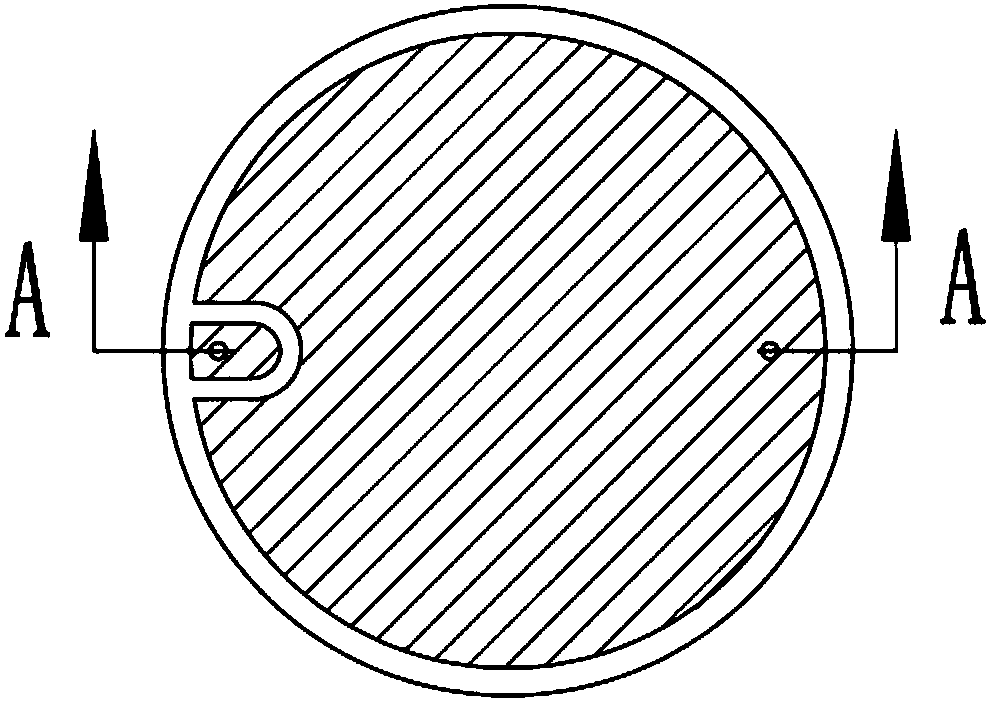

[0040] Such as Figure 1~4 As shown, the double-layer piezoelectric ceramic electro-acoustic element of this embodiment includes two piezoelectric ceramic sheets; the electrodes on the first surface (A surface) of the piezoelectric ceramic sheets include two parts that are not connected to each other, and one part is The large electrode area 11, the other part is the island electrode area 12, the area of the large electrode area is larger than the island electrode area; the large electrode area has a through hole 13, and the island electrode area has a through hole 14, Wherein, the through hole on the island-shaped electrode area deviates from the central position of the island-shaped electrode area. In this embodiment, the island-shaped electrode area is designed to be close to the peripheral position of the piezoelectric ceramic sheet.

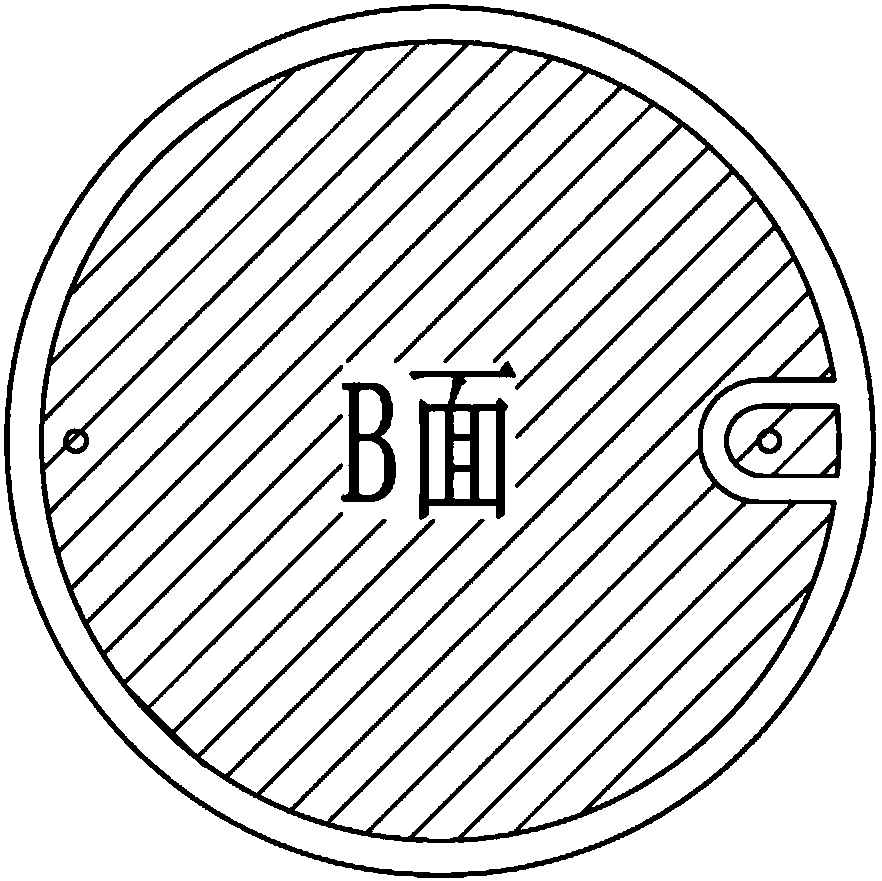

[0041] The electrode pattern on the second surface (B surface) of the piezoelectric ceramic sheet is obtained by rotating the electrode p...

Embodiment 2

[0051] In this embodiment, the island-shaped electrode area is designed near the center of the piezoelectric ceramic sheet.

[0052] The method for preparing the piezoelectric ceramic sheet in this example is similar to that of Example 1, except that the small hole and the island electrode are designed near the center of the piezoelectric ceramic sheet. Prepared piezoelectric ceramics such as Figure 5-9 shown. The double-layer piezoelectric ceramic electroacoustic element of this embodiment includes two piezoelectric ceramic sheets; the electrodes on the first surface (A surface) of the piezoelectric ceramic sheets include two parts that are not connected to each other, and one part is a large electrode area 11. The other part is the island electrode area 12, the area of the large electrode area is larger than the island electrode area; the large electrode area has a through hole 13, and the island electrode area has a through hole 14, wherein the island The through hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com