Straightening machine integrating cleaning and heating functions and using method of straightening machine

A straightening machine and functional technology, applied in the field of straightening machines, can solve the problems of low work efficiency, unfavorable promotion and use, and heavy workload, and achieve the effect of improving work efficiency, facilitating promotion and use, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

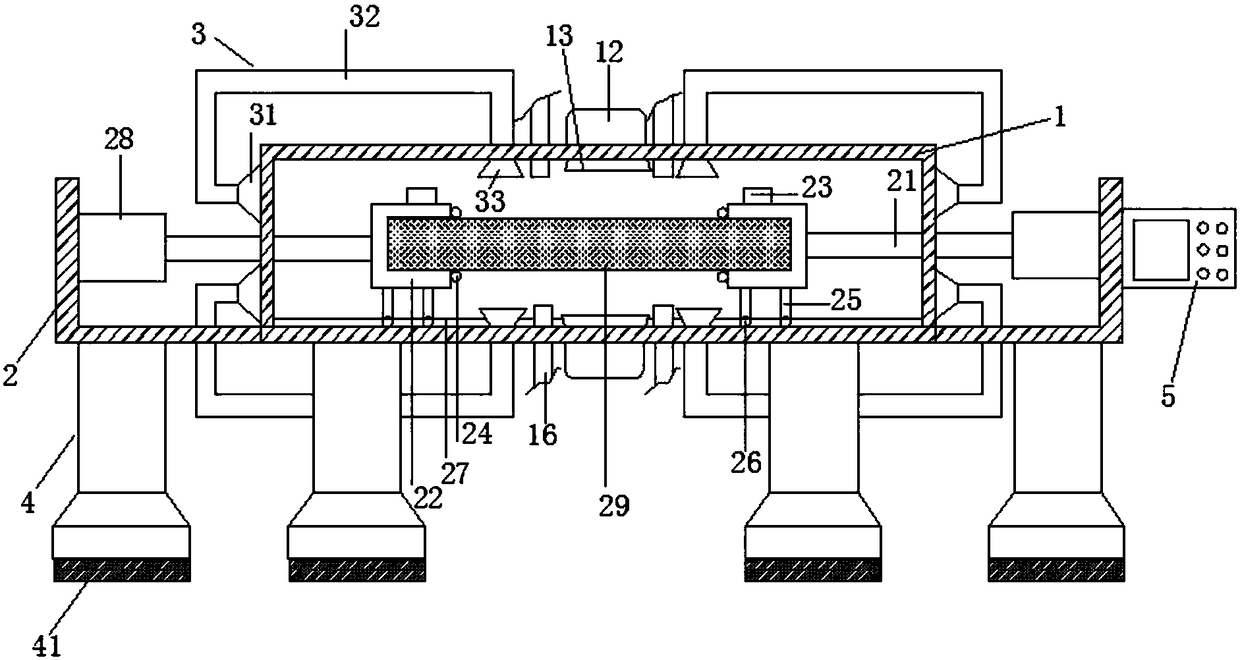

[0026] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0027] like figure 1 As shown, this embodiment provides a straightening machine integrating cleaning and heating functions, including a straightening chamber 1, a support foot 4 and a controller 5, and the straightening chamber 1 is provided with oppositely arranged clampable The clamping device 22 of the profile 29, the clamping device 2 is a U-shaped structure, the clamping device 22 is provided with a cylinder 23, and the upper end surface and the lower end surface of the clamping device 22 are provided with temperature and humidity sensors 24. The temperature and humidity sensor 24 on the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com