Vertical rib corrugated web steel-concrete combined coupling beam

A corrugated web and concrete technology, which is applied to structural elements, building components, and elongated structural components for load-bearing, etc., can solve the problem of low bearing capacity and deformation capacity of reinforced concrete coupling beams, difficult connection of wall pier, steel To solve the problems of high cost of connecting beams, achieve superior seismic energy consumption capacity, enhance collaborative work ability, and ensure the effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

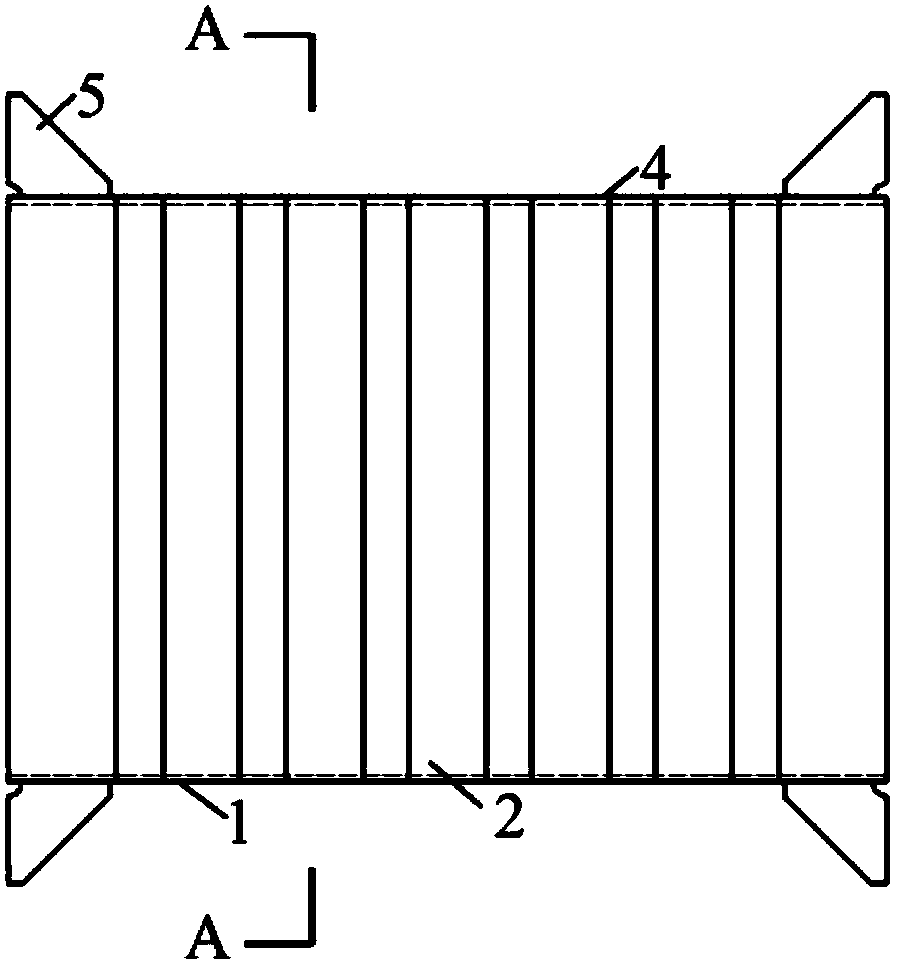

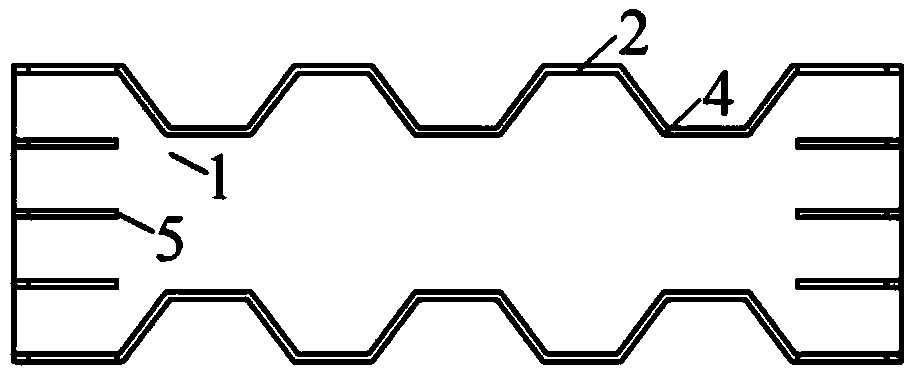

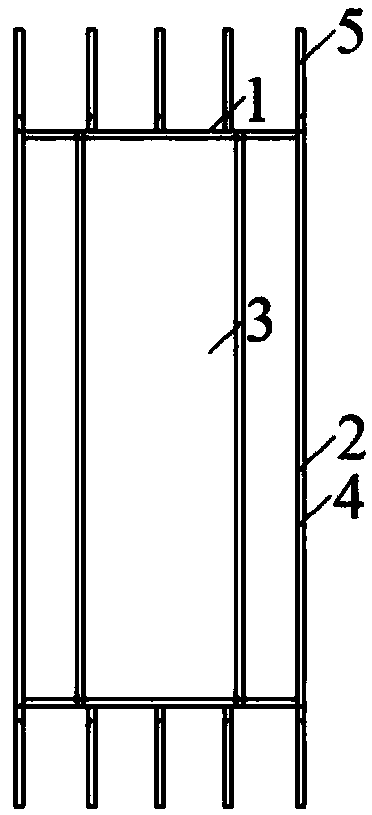

[0023] refer to Figure 1 to Figure 4 , we can know the structure and construction requirements of the present invention.

[0024] Such as Figure 1 to Figure 4 As shown, the present invention proposes a novel coupling beam suitable for double-steel plate-concrete composite wall structure: vertical rib corrugated web steel-concrete composite coupling beam, at least including some steel flanges 1, steel corrugated webs 2 , High damping concrete, butt weld 4, stiffener 5.

[0025] Among them, the steel corrugated web 2 is arranged according to the vertical rib, that is, the plate rib is perpendicular to the beam span direction; the steel flange 1 and the steel corrugated web 2 are connected by a butt weld 4 to form a steel box; the end of the steel box girder and the Shear wall welding; if the shear wall has a connection port, the steel box of the coupling beam and the shear wall shall be poured with high damping concrete 3; The studs are welded inside, and then high-damping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com