Flexible force sensor and preparation method thereof, array device, and application of flexible force sensor

A sensor and flexible force technology, applied in the field of flexible force-sensitive sensor and its preparation, can solve the problems of restricting the practical application of piezoresistive force-sensitive sensor, complex manufacturing technology, expensive cost, etc., to achieve enhanced wearability and sensitivity, enhanced Sensing ability, effect of improving structural elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

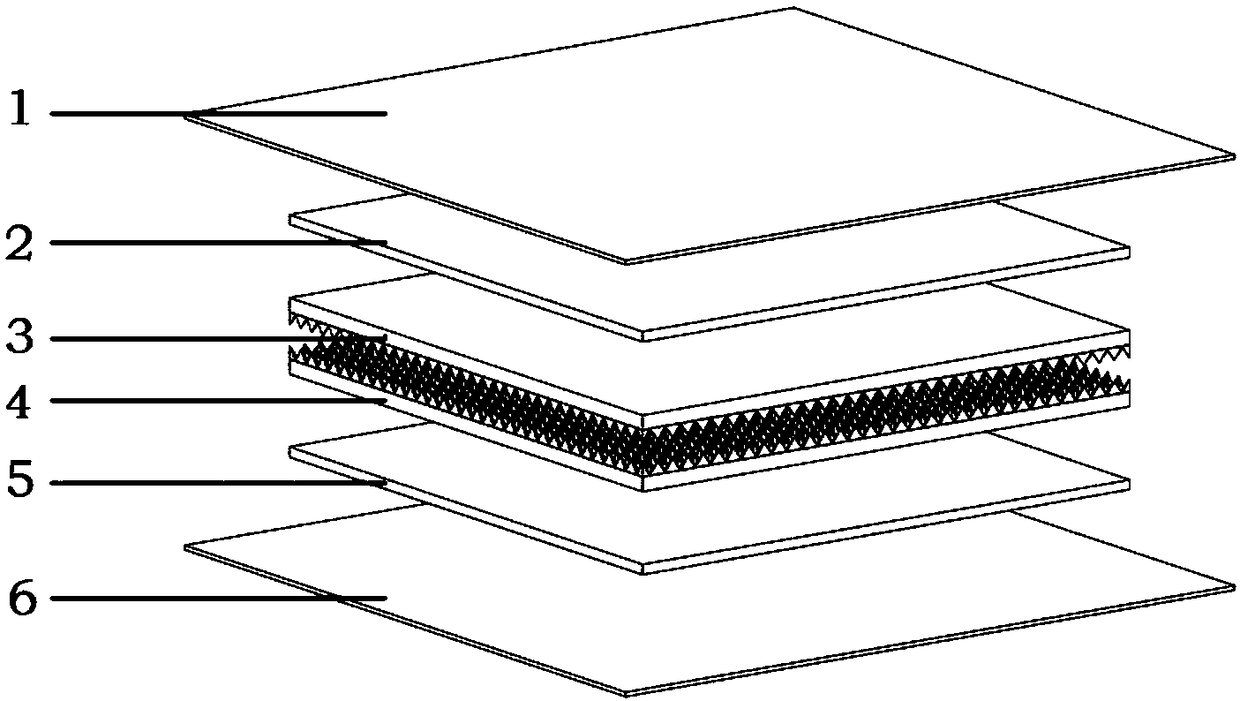

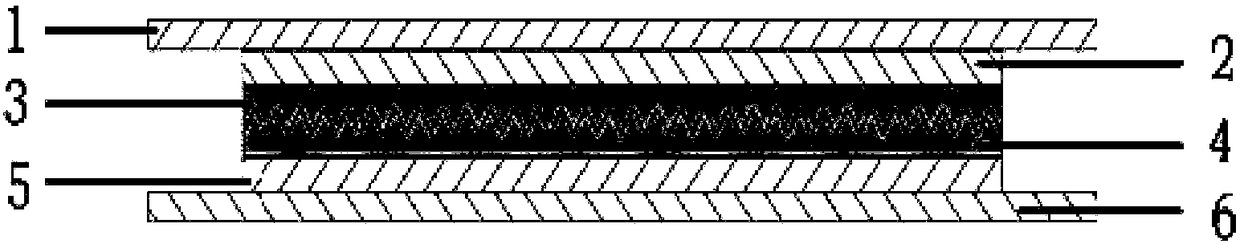

[0024] A method for preparing a flexible force-sensitive sensor provided by an embodiment of the present invention comprises the following steps:

[0025] S1. Mix the PDMS substrate and curing agent in a weight ratio of 5:1 to obtain a PDMS prepolymer; after stirring the PDMS prepolymer once, add carbon black and perform a second stirring to obtain the initial product of carbon black / PDMS ink ; After the second stirring, the bubbles of the initial product of carbon black / PDMS ink were removed under vacuum conditions to obtain carbon black / PDMS ink.

[0026] It should be noted that, in order to ensure more complete mixing and good dispersibility of each component in the mixture, the first stirring and the second stirring in the embodiment of the present invention are both mechanical stirring. Wherein, the time of primary stirring is 5-8min; the time of secondary stirring is 30-40min. Preferably, the time for primary stirring is 5 minutes; the time for secondary stirring is 30 ...

Embodiment 1

[0041] This embodiment proposes a method for preparing a flexible force-sensitive sensor, which includes the following steps:

[0042] First, mix the PDMS substrate and the curing agent at a weight ratio of 5:1 to obtain a PDMS prepolymer; after stirring the PDMS prepolymer once with a mechanical stirrer, add carbon black at normal temperature and pressure and perform a second Stir to obtain the primary product of carbon black / PDMS ink; after the second stirring, remove the bubbles of the primary product of carbon black / PDMS ink under vacuum conditions to obtain carbon black / PDMS ink. Wherein, the primary stirring time is 5 minutes, and the secondary stirring time is 30 minutes.

[0043] Secondly, the carbon black / PDMS ink was spin-coated on the ground glass sheet mold with a microstructure on the surface at a speed of 600 revolutions per minute by a spin-coating machine, and cured at 70°C for 2 hours, and then the cured The carbon black / PDMS ink was peeled from the ground gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com