Fast screening method for battery internal resistance and capacity

A screening method and technology in the battery, applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as time-consuming, inability to successfully complete assembly line operations, and screening difficulties, and achieve improved The effect of screening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] The basic parameters of the selected power-type ternary lithium batteries are shown in Table 1, and the appearance inspection of multiple battery cells is performed at a visual inspection speed of 100Wh / s, and the battery cells with unqualified appearance are removed;

[0106] Table 1: Basic parameters of power ternary lithium battery

[0107]

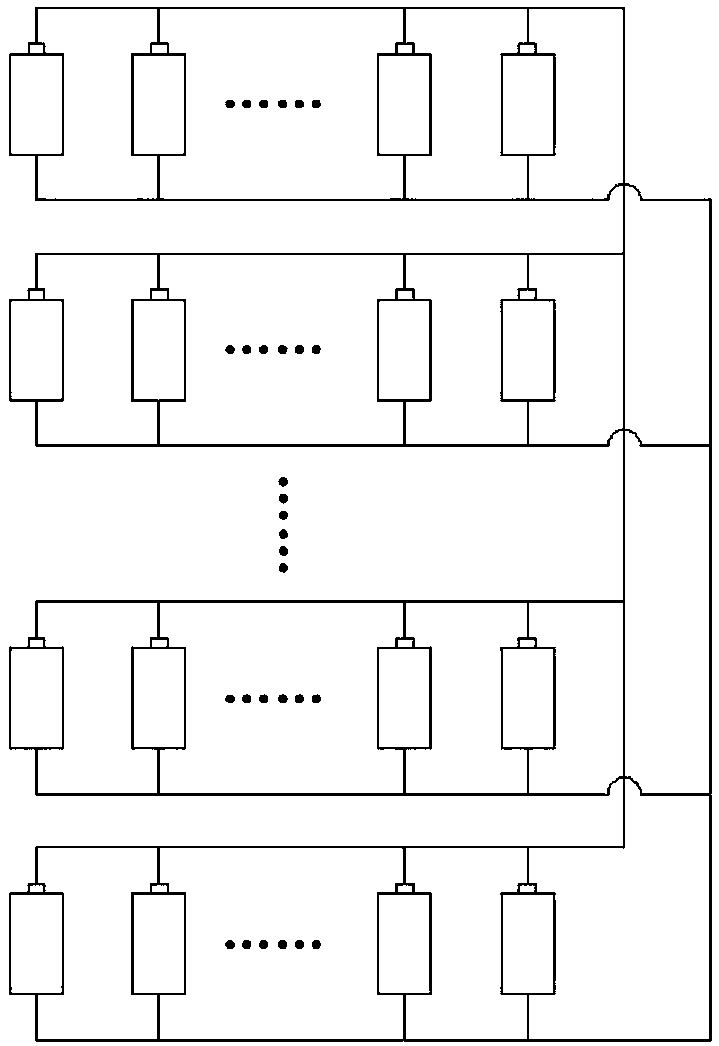

[0108] Then carry out parallel equalization on the battery cells with qualified appearance, and connect the positive pole of each battery cell to the positive pole and the negative pole to the negative pole through the parallel connection equipment, such as figure 1 As shown, in the process of parallel equalization, the battery cells with high voltage charge the battery cells with low voltage. It takes 2 hours to equalize the parallel connection of monomers, then the parallel equipment should meet the equalization capacity of 720KWh / batch, and the voltage of each monomer after equalization is the same as 3.52V;

[0109] Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com