Electrical engineering automation distribution cabinet

A technology of electrical engineering and distribution box, applied in substation/distribution device casing, electrical components, substation/switch layout details, etc. problem, to achieve the effect of improving the shock absorption effect, improving the heat dissipation effect, and improving the antistatic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] The present invention will be further explained below in conjunction with the drawings:

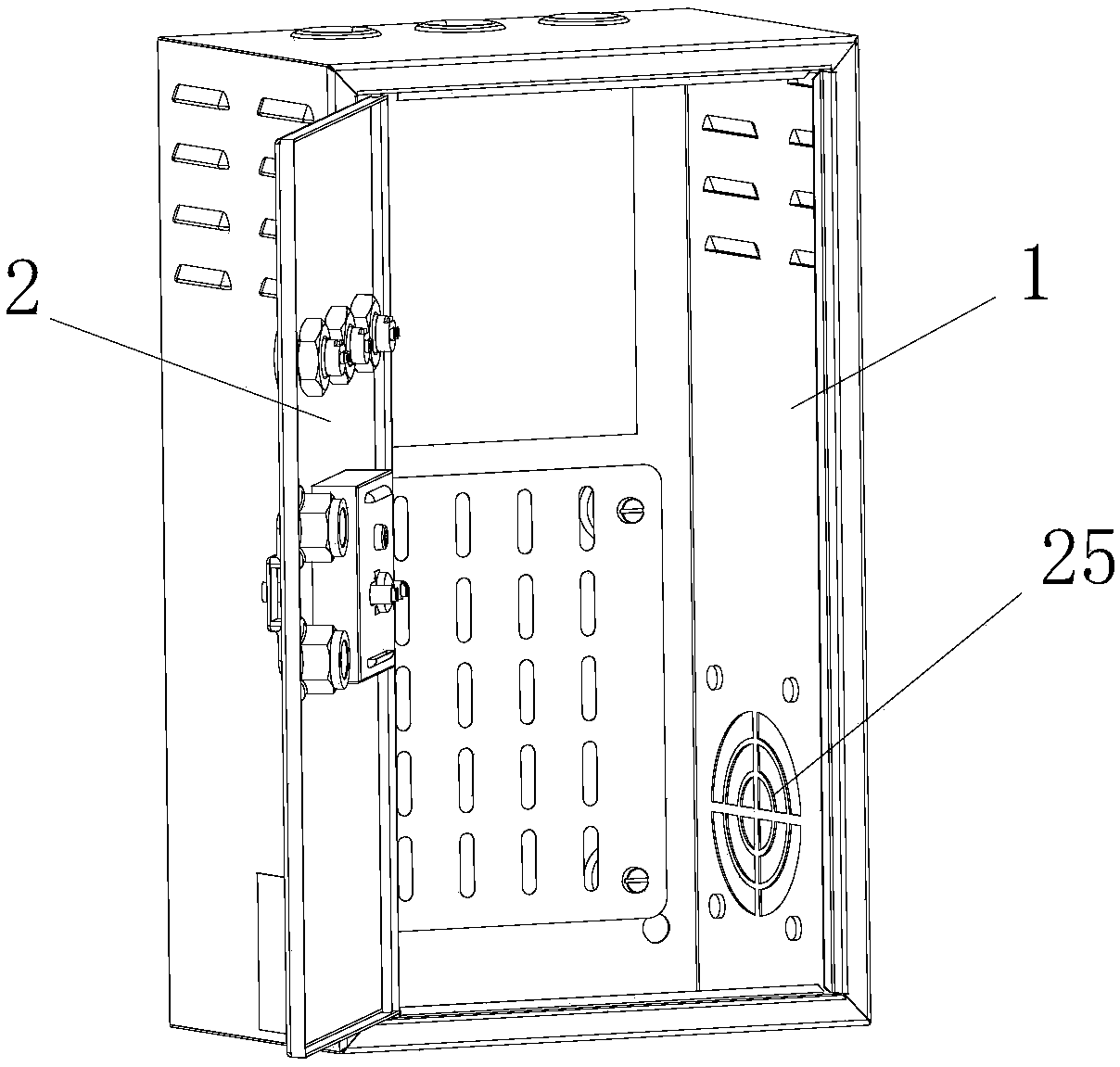

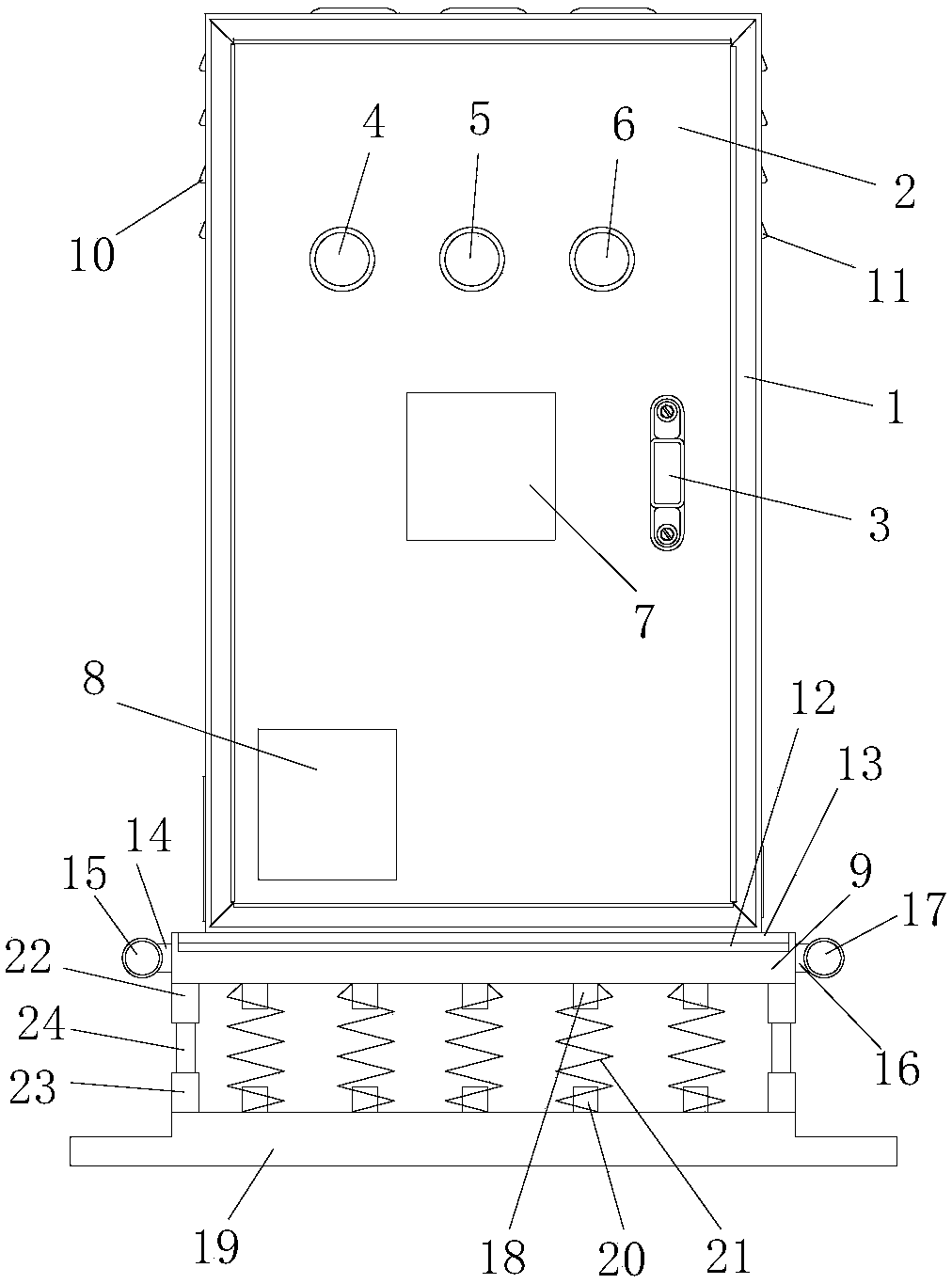

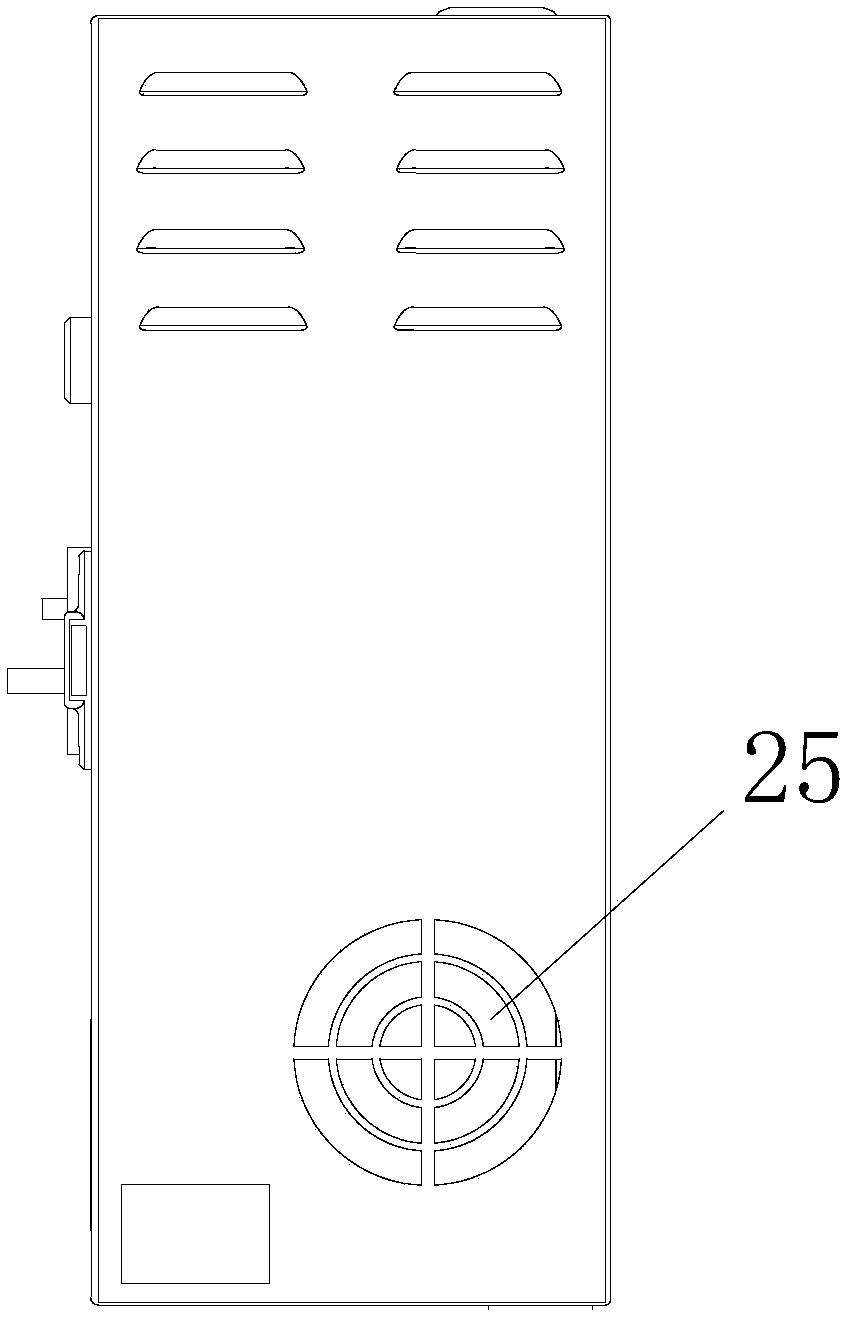

[0018] Such as Figure 1-Figure 3 As shown, the electrical engineering automation power distribution box includes a power distribution box body 1, a box door 2 is movably installed on one side of the power distribution box body 1 through a hinge, and the box door 2 is processed There is a lock hole, a lock core is installed in the lock hole, a handle 3 is locked and installed on the lock core, a key hole is provided on the handle 3, the distribution box body 1 and the box door 2 Forming a closed structure, the power distribution box body 1 has a cavity, and power distribution devices are installed in the cavity; it is characterized in that a first button 4, a second button 5, and a The third button 6, and the first button 4, the second button 5, and the third button 6 are on the same straight line. An observation window 7 is provided on the box door 2, and the cross section of the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com