Method for monitoring a machine tool, and controller

A technology of control department and machine tool, which is applied in computer control, general control system, program control, etc., can solve the problems of false alarms and weaken the sensitivity of monitoring methods, and achieve the effect of reducing the number of false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific implementation plan

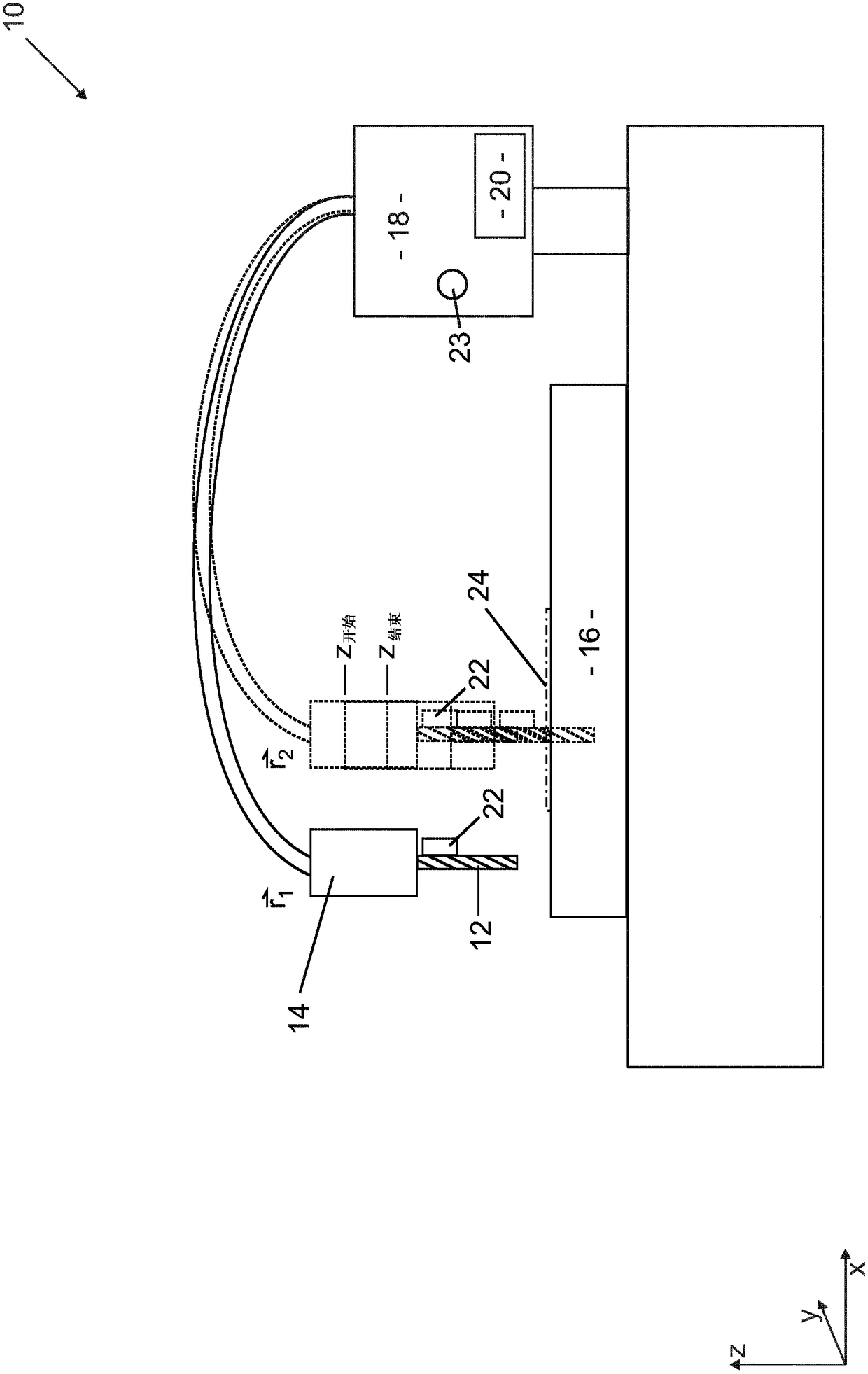

[0041] figure 1 A machine tool 10 with a tool 12 in the form of a drill is shown schematically. The tool 12 is driven by a spindle 14 schematically depicted. The workpiece 16 is clamped on the machine tool 10, and the workpiece is cut by the tool 12 within the scope of the machining process.

[0042] The spindle 14 and thus the tool 12 can be positioned in three spatial coordinates, namely along the x-direction, y-direction and z-direction. The corresponding drive is controlled by an electric control unit 18, which includes a digital memory 20. The computer numerical control program is stored in the digital memory 20. A program for executing the method according to the present invention is also stored in the digital memory 20 or a digital memory separated from it in space.

[0043] In addition, the machine tool may also have a sensor 22 schematically drawn, such as a force sensor or an acceleration sensor, which measures the acceleration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com