Thermoelectric module

A technology of thermoelectric modules and thermocouples, which is applied in the manufacture/processing of circuits, thermoelectric devices, electrical components, etc., can solve problems such as low output power, lower output voltage, lower output or performance characteristics, etc., and achieve high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

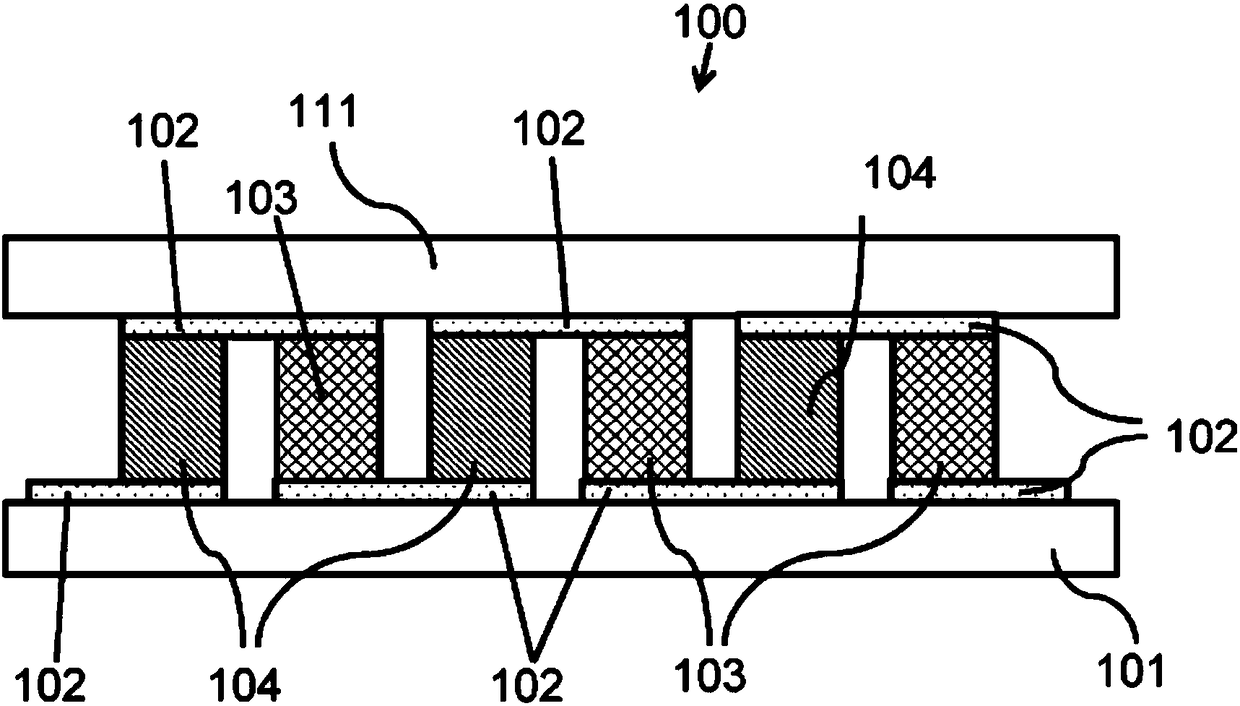

[0048] figure 1 is a side view of a standard thermoelectric module 100 known in the art. The thermoelectric module 100 includes a bottom substrate 101 , electrical interconnects 102 disposed on the bottom substrate 101 , n-type thermoelectric elements 104 , p-type thermoelectric elements 103 , and electrical interconnects 102 disposed on a top substrate 111 . Electrical interconnect 102 connects n-type 104 and p-type 103 thermoelectric elements in series, forming a series of electrically connected thermocouples.

[0049] The thermoelectric module 100 may be electrically connected to an external power source to provide electrical cooling or heating, or thermally connected between temperature differences to generate electricity.

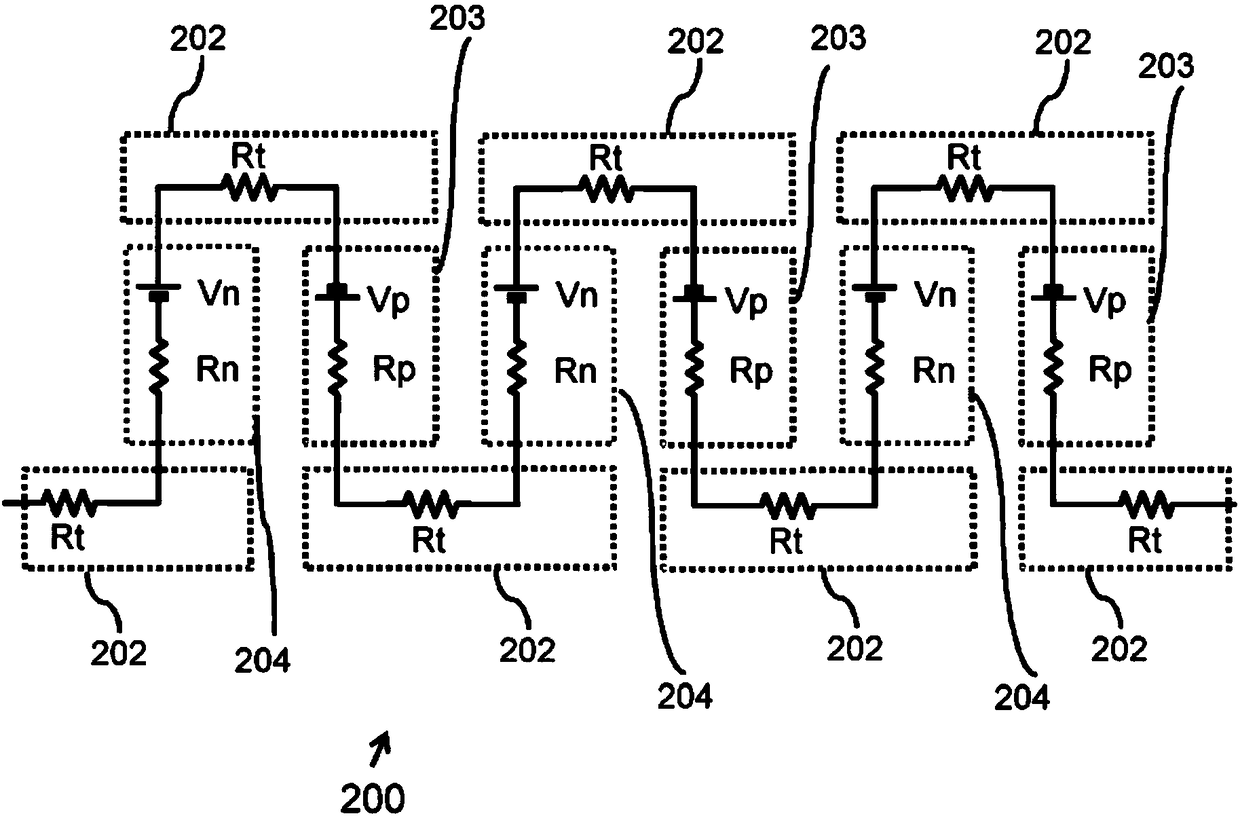

[0050] figure 2 shown in figure 1 Electrical schematic diagram of the thermoelectric module in . Thermoelectric elements 103 and 104, and the electrical interconnects 102 interfacing therewith, can be represented by equivalent circuits 203 and 204...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com