Conductive composition for low frequency emi shielding

一种组合物、混合物的技术,应用在分散在不导电无机材料中的导电材料、磁场/电场屏蔽、电路等方向,能够解决不能提供足够屏蔽有效性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] volume resistance

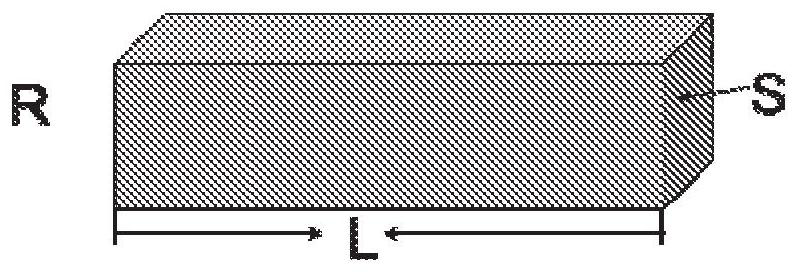

[0124] figure 1 Exemplary shapes used to define the term "volume resistance" are shown.

[0125] R=ρL / S[Ω, ohm]

[0126] ρ: at 25°C, with a length of 1 m and a cross-sectional area of 1 mm 2 The (volume) resistivity of the conductor.

[0127] Volume resistance: ρ=RS / L[μΩ m, μohm.m, 10E-4ohm.em]

[0128] Agilent 34401A digital multimeter, Gen Rad 1689 Precision RLC Digibridge were used in the measurement.

[0129]A special four point probe test fixture is made of acrylic material with four spring loaded contact points. Set the contacts into the acrylic so that the current contacts are two inches (5.08 em) apart, the voltage contacts are between two current contacts, and the voltage contacts are 0.5 inches (1.27 cm) from each current contact .

[0130] Sample Preparation:

[0131] Two rolls of 3M Magic Scotch Tape were loaded into the jig 0.1" (0.254 cm) apart.

[0132] Slide a cleaned glass slide with two parallel Scotch tapes 0.1" (0.254 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| actual density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com