Processing technology of crock pork rib soup

A processing technology and rib soup technology, which is applied in food science, food preservation, food ingredients as taste improvers, etc., can solve the problems of not being suitable for large-scale industrial production, extensive production technology, and short shelf life, so as to improve soup juice Effects of texture and nutritional value, increase of umami and mellowness, and mellow aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

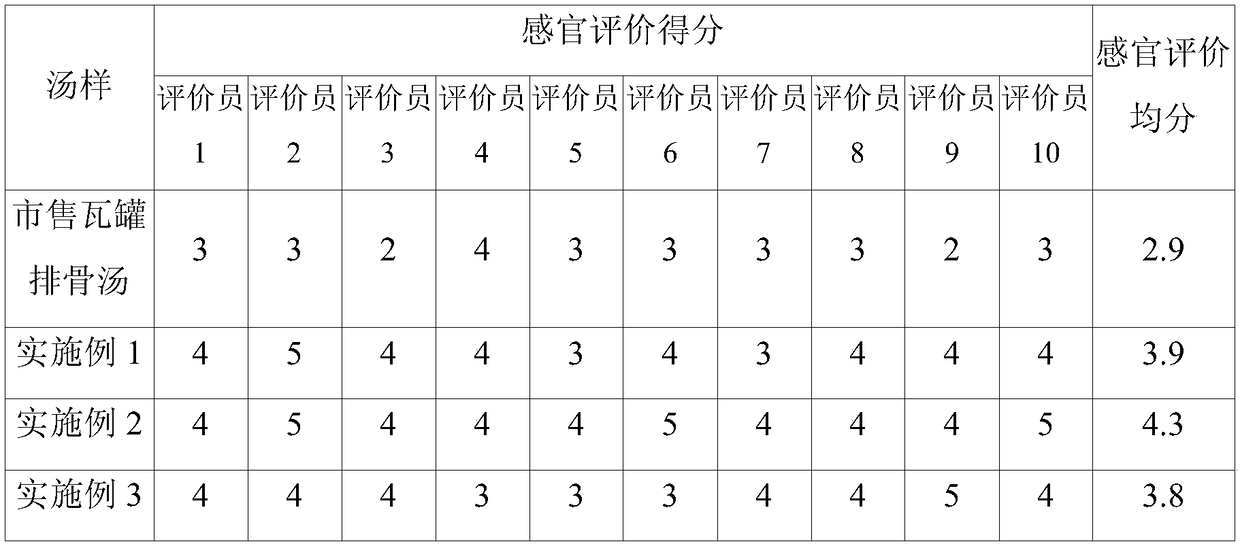

Examples

Embodiment 1

[0019] (1) raw material preparation: by weight, prepare the following raw materials, 300 parts of pork ribs, 500 parts of pork ribs, 300 parts of shrimp shells, 300 parts of chicken skeletons, 10 parts of ginger, 8 parts of salt, and the ginger is cut into shreds;

[0020] (2) Boil soup: Cut the pork ribs into 5-10cm sections, soak them in clean water, wash them with clean water and drain them after soaking the blood; add the drained pork ribs to boil Boil in clear water for 3 minutes, pour off the water, and wash the pork ribs again; add the cleaned pork ribs to clean water and simmer for 1 hour on high heat, then add shrimp shells and chicken skeletons, mix and simmer over low heat Stew for 2 hours, filter out the bone and meat, and keep the soup for later use;

[0021] (3) Treatment of pork ribs: Cut the pork ribs into small pieces and soak them in clean water for half an hour. When the blood is soaked out, wash them with clean water and drain them; , pour in the shredded ...

Embodiment 2

[0026] (1) raw material preparation: by weight, prepare the following raw materials, 500 parts of pork ribs, 500 parts of pork ribs, 200 parts of shrimp shells, 200 parts of chicken skeletons, 8 parts of ginger, 10 parts of salt, and the ginger is cut into shreds;

[0027] (2) Boil soup: Cut the pork ribs into 5-10cm sections, soak them in clean water, wash them with clean water and drain them after soaking the blood; add the drained pork ribs to boil Boil in clean water for 4 minutes, pour off the water, and wash the pork ribs again; add the cleaned pork ribs to clean water and simmer for 0.5 hours on high heat, then add shrimp shells and chicken skeletons, mix and simmer over low heat Stew for 3 hours, filter out the bone and meat, and keep the soup for later use;

[0028] (3) Treatment of pork ribs: Cut the pork ribs into small pieces and soak them in clean water for half an hour. When the blood is soaked out, wash them with clean water and drain them; , pour in the shredd...

Embodiment 3

[0033] (1) raw material preparation: by weight, prepare the following raw materials, 800 parts of pork ribs, 400 parts of pork ribs, 100 parts of shrimp shells, 100 parts of chicken skeletons, 5 parts of ginger, 11 parts of salt, and the ginger is cut into shreds;

[0034] (2) Boil soup: Cut the pork ribs into 5-10cm sections, soak them in clean water, wash them with clean water and drain them after soaking the blood; add the drained pork ribs to boil After boiling in clean water for 5 minutes, pour off the water, and wash the pork ribs again; add the cleaned pork ribs to clean water and simmer for 0.5 hours on high heat, then add shrimp shells and chicken skeletons, mix and simmer over low heat Stew for 3 hours, filter out the bone and meat, and keep the soup for later use;

[0035] (3) Treatment of pork ribs: Cut the pork ribs into small pieces and soak them in clean water for half an hour. When the blood is soaked out, wash them with clean water and drain them; , pour in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com