Ginger detergent processed at ultrahigh pressure and preparation method thereof

A detergent and ultra-high pressure technology, applied in the direction of chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of insignificant sterilization effect, human health damage, skin irritation, etc., to achieve rich foam, The effect of improving utilization efficiency and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

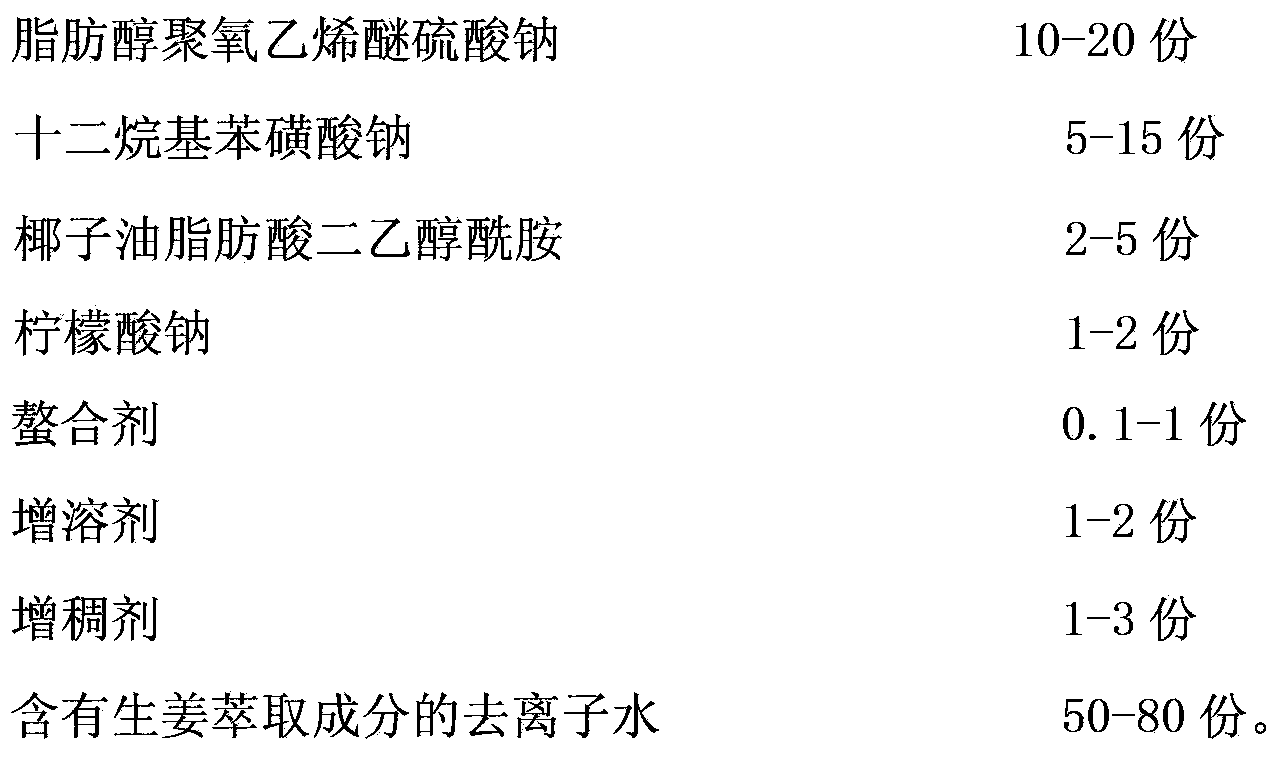

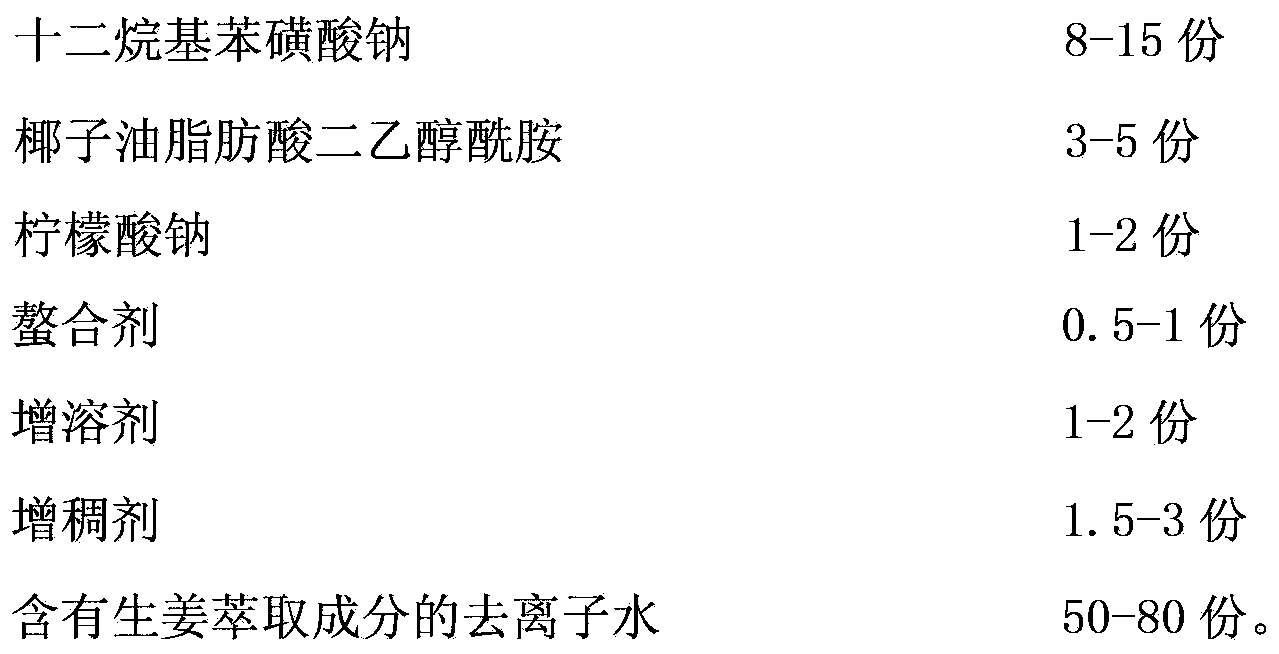

Method used

Image

Examples

Embodiment 1

[0061] Fatty alcohol polyoxyethylene ether sodium sulfate 20g, sodium dodecylbenzenesulfonate 15g, coconut oil fatty acid diethanolamide 2g, ethylenediaminetetraacetic acid 0.1g, urea 1g, sodium citrate 1g, sodium chloride 3g, The amount is deionized water containing ginger extract.

Embodiment 2

[0063] Fatty alcohol polyoxyethylene ether sodium sulfate 10g, sodium dodecylbenzenesulfonate 8g, coconut oil fatty acid diethanolamide 5g, ethylenediaminetetraacetic acid 0.5g, urea 2g, sodium citrate 2g, sodium chloride 3g, The amount is deionized water containing ginger extract.

Embodiment 3

[0065] Fatty alcohol polyoxyethylene ether sodium sulfate 20g, sodium dodecylbenzenesulfonate 8g, coconut oil fatty acid diethanolamide 2g, ethylenediaminetetraacetic acid 0.1g, urea 1g, sodium citrate 1g, sodium chloride 3g, The amount is deionized water containing ginger extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com