Super-hydrophobic super-oleophylic carbon material and preparation method thereof

A super-lipophilic, carbon material technology, applied in the field of material modification and adsorption of new materials, can solve the problems of reduced practical value, lengthy preparation process, difficult to collect raw materials on a large scale, etc. The effect of economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The used JD Express packaging corrugated boxes were crushed in a Philips HR2104 / 90 hand-held pulverizer juicer for 5 minutes into a fluffy shape, placed in a tube furnace, and carbonized at 400, 600, and 800°C for 2 hours under the protection of nitrogen to obtain Hydrophobic and lipophilic carbon materials for corrugated cardboard precursors.

[0032] The effect of different crushing and carbonization temperatures on the hydrophobic and lipophilic properties of corrugated cardboard precursor carbon materials shows that the carbon materials obtained by carbonization at 600°C after crushing for 5 minutes have the best superhydrophobic and super lipophilic properties.

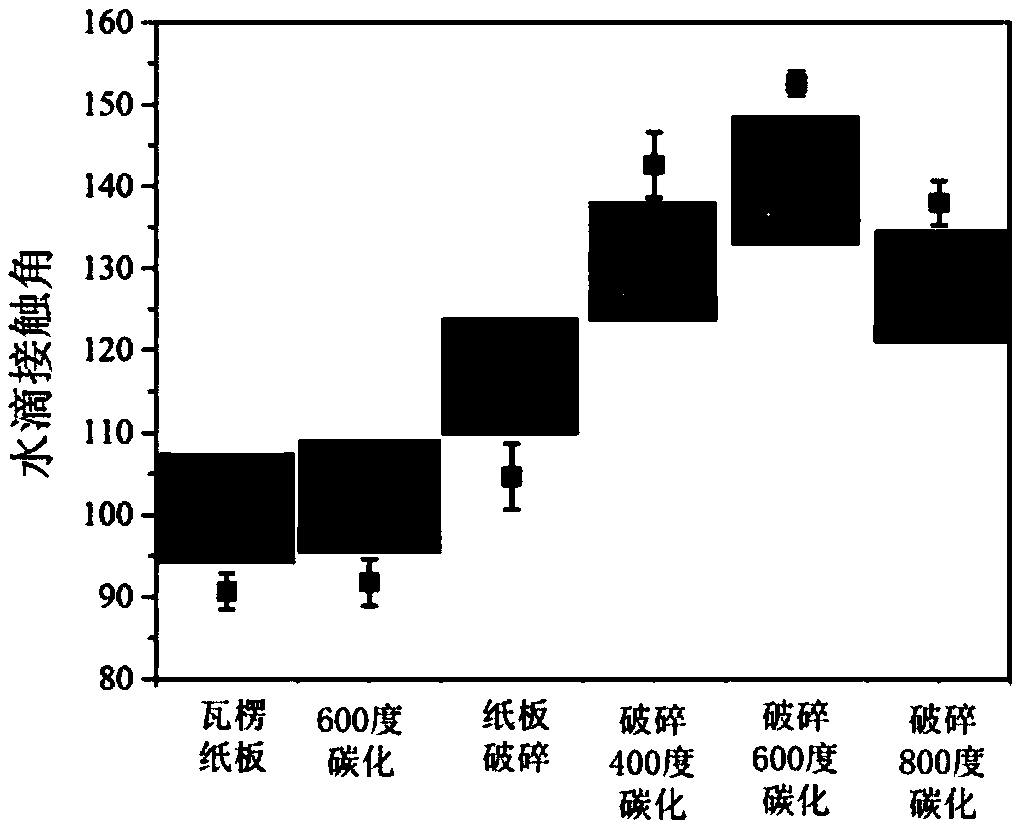

[0033] figure 1 It is the water drop contact angle of the carbon material obtained by pulverizing the corrugated cardboard prepared in Example 1 and carbonizing it at different carbonization temperatures. Depend on figure 1 It can be seen that the carbon material obtained by carbonization at 600°C after ...

Embodiment 2

[0041] Put the used Jingdong Express packaging corrugated box into a Baijie BJ-150 stainless steel pulverizer for 5 minutes and pulverize it into a fluffy shape, put it in a tube furnace, and carbonize it at 600°C for 2 hours under the protection of nitrogen to obtain the corrugated cardboard precursor carbon material .

[0042] After testing, the obtained carbon material has super-hydrophobic and super-oleophilic properties.

Embodiment 3

[0044] Put the used Tmall express packaging corrugated box in the Oakes HX-PB1250 wall-breaking food processor and crush it into a fluffy shape for 5 minutes, place it in a tube furnace, and carbonize it at 600°C for 2 hours under the protection of nitrogen to obtain the corrugated cardboard precursor carbon Material.

[0045] After testing, the obtained carbon material has super-hydrophobic and super-oleophilic properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com