Coal ash layered smashing device for chemical experiment

A crushing device and chemical experiment technology, applied in the field of grinding and processing machinery, to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

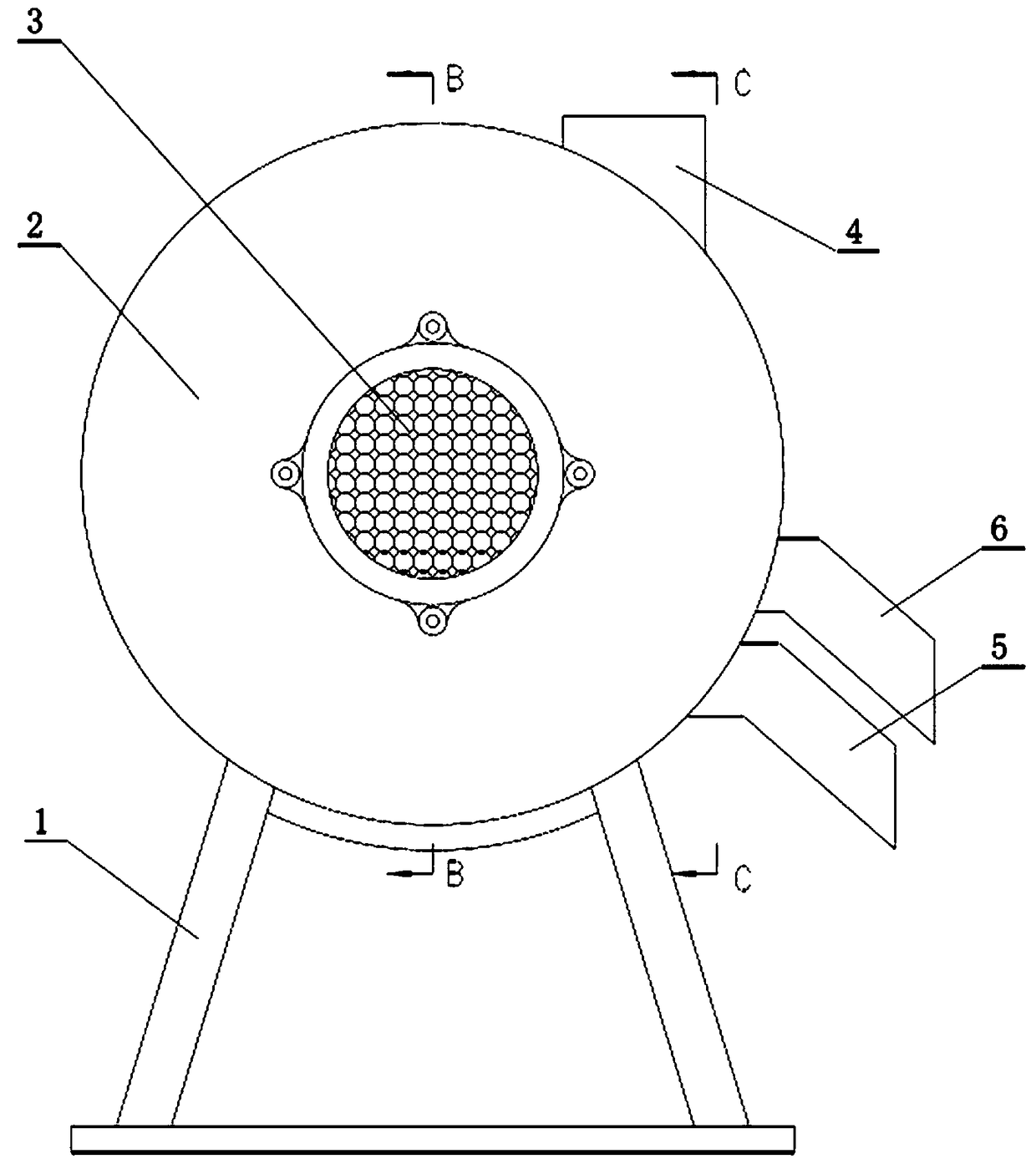

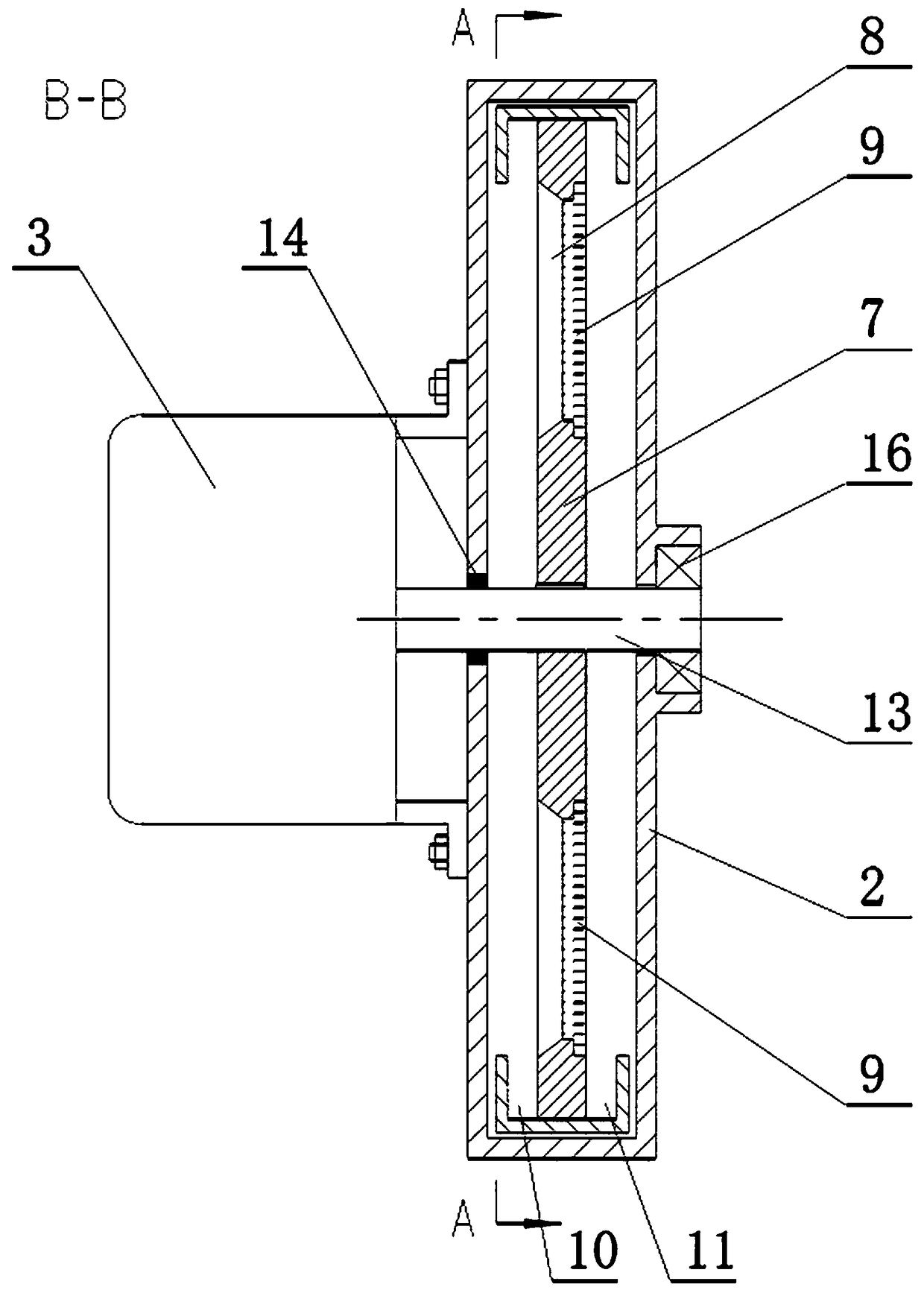

[0021] Embodiment 1: A kind of fly ash layered crushing device for chemical experiments, see figure 1 and Figure 4 As shown, it includes a sealing body 2 fixed on the bracket 1, and the sealing body 2 includes a sealing door fixed on the main body part and the side of the bracket 1. The motor 3 is installed on one side of the sealing body 2 , and the rotating shaft of the motor extends into the inside of the sealing body 2 and the turntable main body 7 is installed. At the same time, a feed hopper 4 is arranged on one side of the sealing body 2 .

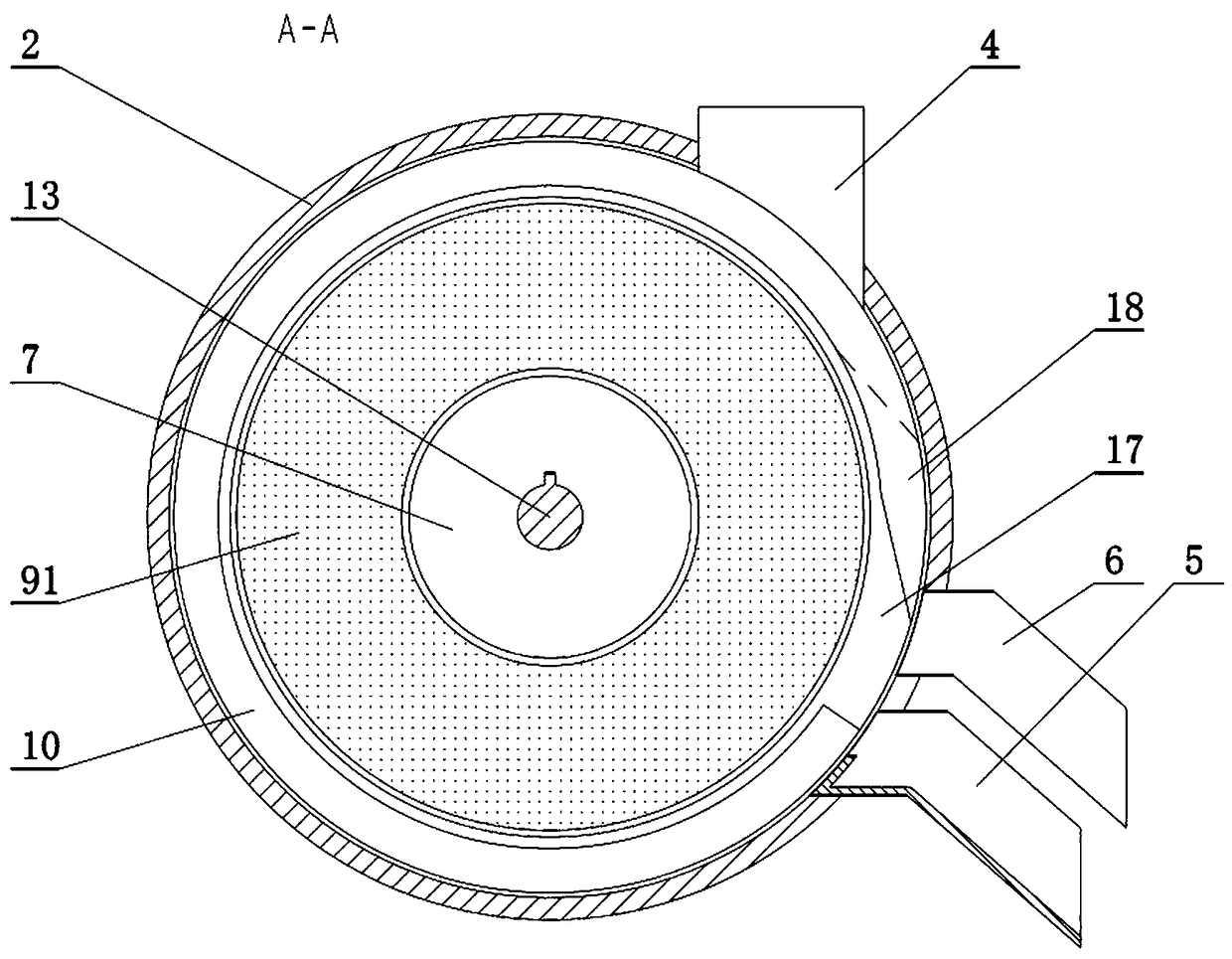

[0022] see image 3 As shown, the turntable main body 7 includes an annular transparent area, which divides the turntable main body 7 into an inner disc body and an outer ring body, and the two are connected as a whole through the radial connecting rod of the annular area.

[0023] An annular rubbing filter screen 9 is matched and fixed in the annular transparent area, see Figure 5 As shown, the front side of the annular rubbi...

Embodiment 2

[0026] Embodiment 2: on the basis of embodiment 1, see Figure 4 As shown, on the inner wall of the sealing body 2 near the back side of the ring-shaped grinding filter screen 9, a rolling roller 19 is installed through the axle seat, and at the same time, on the sealing body near the front side of the ring-shaped grinding filter screen 9 2. Support rollers 20 are installed on the inner wall, and the support rollers 20 and rolling rollers 19 are respectively tangent to the two sides of the annular rubbing filter screen 9 on the same straight line. Utilize rolling roller 19 to carry out rolling on the back side of annular rubbing filter screen 9, make the powder passing through the screen continue to be rolled. The lamination roller 19 is supported by the support roller 20 , thereby increasing the lamination strength of the lamination roller 19 . In the present invention, since the ring-shaped grinding filter screen 9 is rotating, the linear speeds of its inner edge and outer ...

Embodiment 3

[0027] Embodiment 3: On the basis of Embodiment 2, on the inner wall of the sealing body 2 near the back side of the annular grinding filter screen 9, a brush layer parallel to the axial direction is fixed, and the end face of the brush layer is Plane and parallel with the ring-shaped grinding filter screen 9 back sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com