Efficient glass cleaning machine for glass making

A glass cleaning and glass manufacturing technology, which is applied to the cleaning method using tools, the cleaning method using liquid, drying machines, etc., can solve the problems of unsatisfactory cleaning effect and residual debris on the glass surface, and is conducive to popularization and use , The cleaning effect is remarkable, and the cleaning effect is thorough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

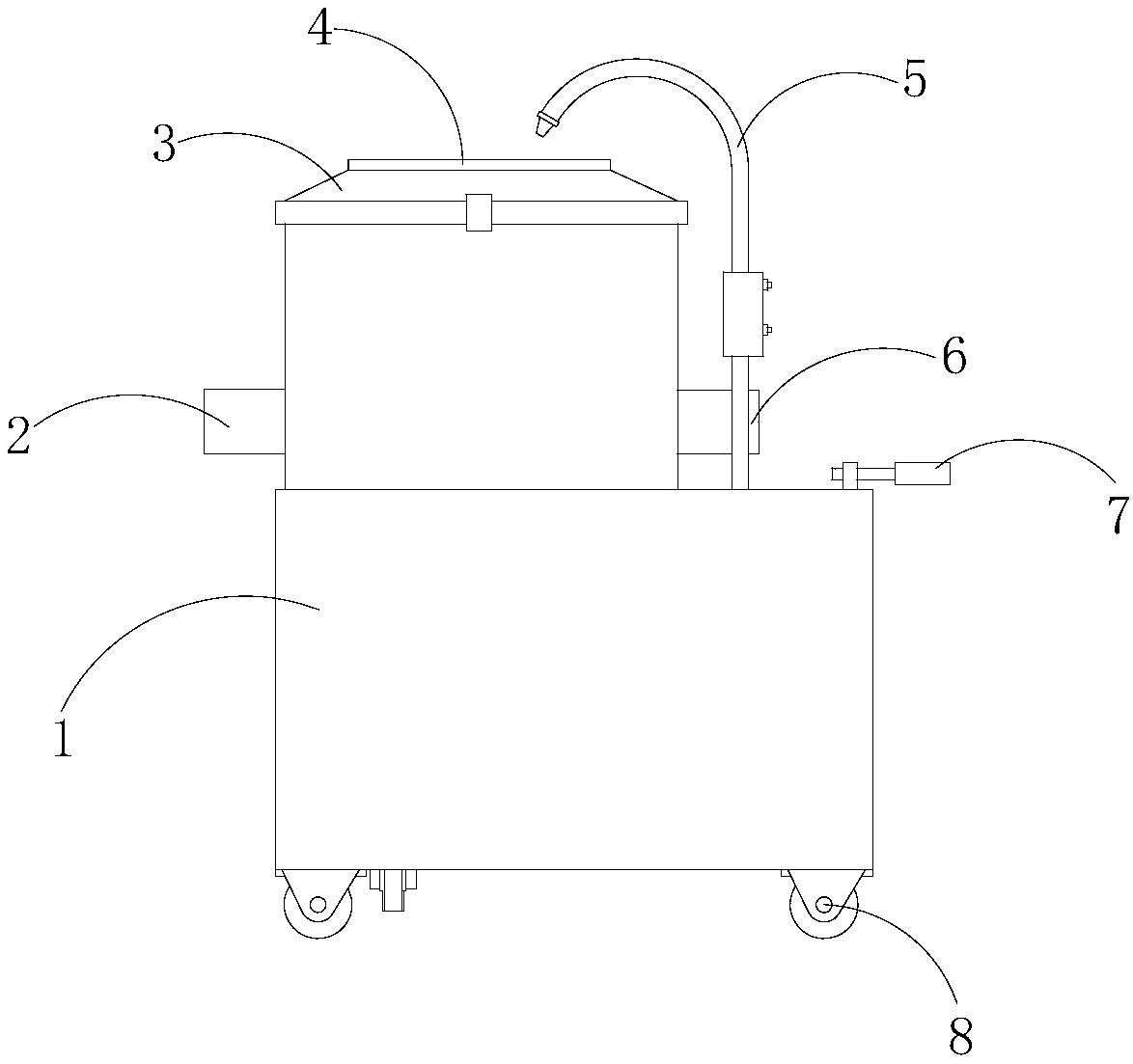

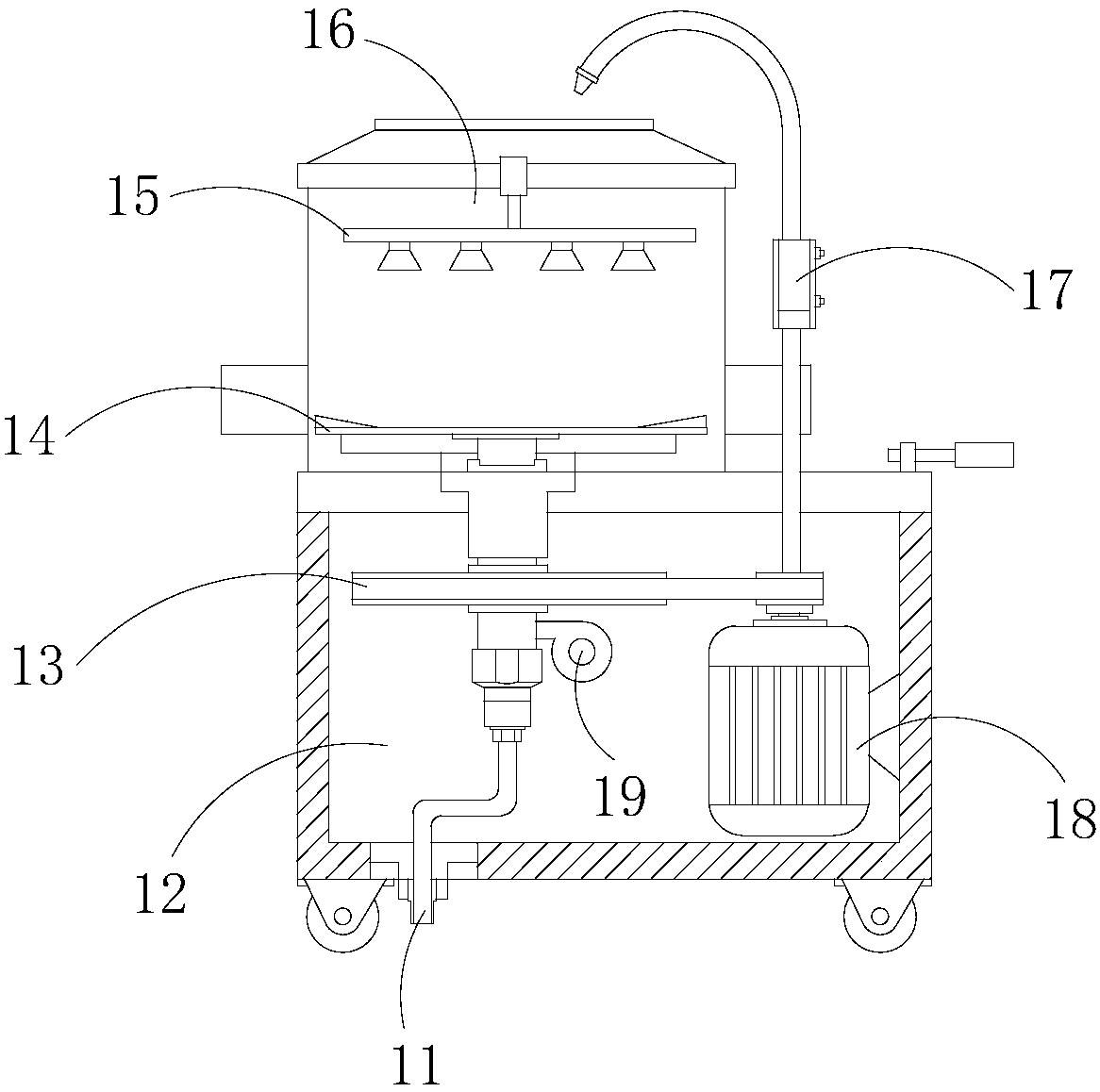

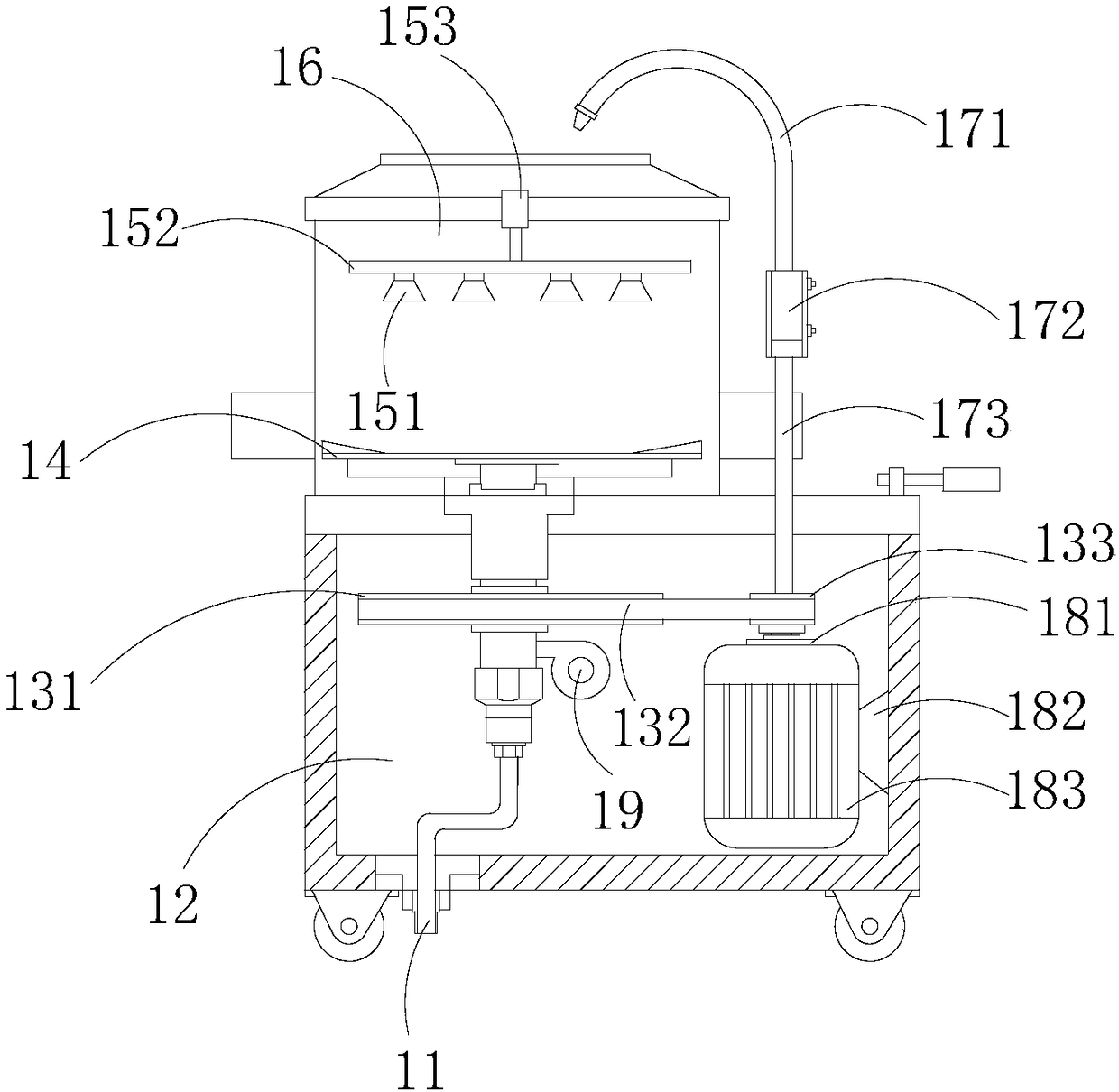

[0021] Such as Figure 1-Figure 5As shown, the present invention provides a high-efficiency glass cleaning machine for glass manufacturing, the structure of which includes: a cleaning device 1, a glass inlet and outlet 2, a washing machine 3, an upper lift cover 4, a faucet 5, a transparent observation port 6, a handle 7, a rubber Universal wheel 8, the cleaning device 1 is installed vertically on the upper end of the rubber universal wheel 8 and matched with the faucet 5, the cross-section of the glass inlet and outlet 2 is a rectangular structure and is horizontally attached to the left end of the cleaning device 1 and welded together , the flushing cabinet 3 is vertically installed on the upper end of the cleaning device 1 and is an integrated structure, the upper flip cover 4 is vertically nested on the top of the flushing cabinet 3 and is interlocked, and the faucet 5 is horizontally fixed on the flushing cabinet 3. The right end is mechanically connected to the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com