A kind of method for preparing glycolic acid compound

A technology of glycolic acid and compounds, applied in the field of preparation of glycolic acid compounds, can solve the problems of high cost of glycolic acid, high safety requirements, harsh reaction conditions, etc., achieve non-corrosive separation and reuse, and easy separation and reuse , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

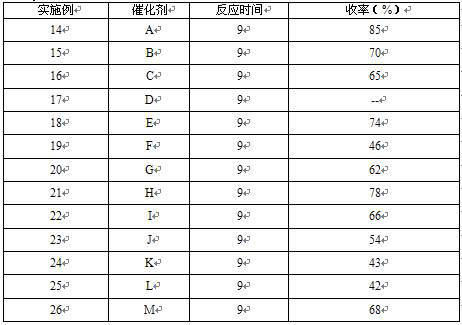

Examples

preparation example Construction

[0017] In the method for preparing glycolic acid compounds provided by the present invention, the method uses 1,3-dihydroxyacetone as a reaction raw material, in the presence of a composite catalyst and an oxidizing agent, in a reaction medium, at a reaction temperature of 0-100°C Under the condition of catalytic reaction in the reactor for 2-48 hours, so as to obtain the glycolic acid compound.

[0018] In the present invention, the term "composite catalyst" refers to a catalyst composed of two or more metal oxides, or at least one metal oxide and at least another metal element, or at least one metal element and activated carbon. into a catalyst. Preferably, the composite catalyst used is composed of oxides of at least two selected from the following metals, or is composed of oxides of at least one of the following metals and at least another metal element, or is selected from At least one of the following metal elements and activated carbon composition: aluminum, bismuth, z...

Embodiment 1

[0029] Weigh 2.2 mg (0.013 mmol) of commercially available copper chloride dihydrate and add it to 4 mL of acetone, and stir magnetically in a 50 mL round bottom flask at room temperature. After the dissolution is complete, add such as 400mg γ-Al under stirring 2 o 3As a carrier, stirring was continued at room temperature for 24 h to obtain a solid powder. Calcined in a muffle furnace at 450 °C for 4 hours, the catalyst was obtained as a gray powder, which was analyzed by XRD, XPS, TEM and EXAFS (pattern not shown), indicating that the catalyst was Cu / Al 2 o 3 Complex, denoted as catalyst A.

Embodiment 2

[0031] Weigh 3.1 mg (0.013 mmol) of commercially available copper nitrate trihydrate and add it to 4 mL of acetone, and stir magnetically in a 50 mL round bottom flask at room temperature. After the dissolution is complete, add such as 400mg Al under stirring 2 o 3 As a carrier, stirring was continued at room temperature for 24 h to obtain a solid powder. Calcined in a muffle furnace at 450 °C for 4 hours, the catalyst was obtained as a gray powder, which was analyzed by XRD, XPS, TEM and EXAFS (pattern not shown), indicating that the catalyst was Cu / Al 2 o 3 The complex is denoted as Catalyst B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com