A kind of universal black masterbatch and preparation method thereof

A black masterbatch, a general-purpose technology, applied in the field of general-purpose black masterbatch and its preparation, can solve the problems of low carrier resin content, heavy odor, high production cost, reduce crushing shear friction, and simple preparation process , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

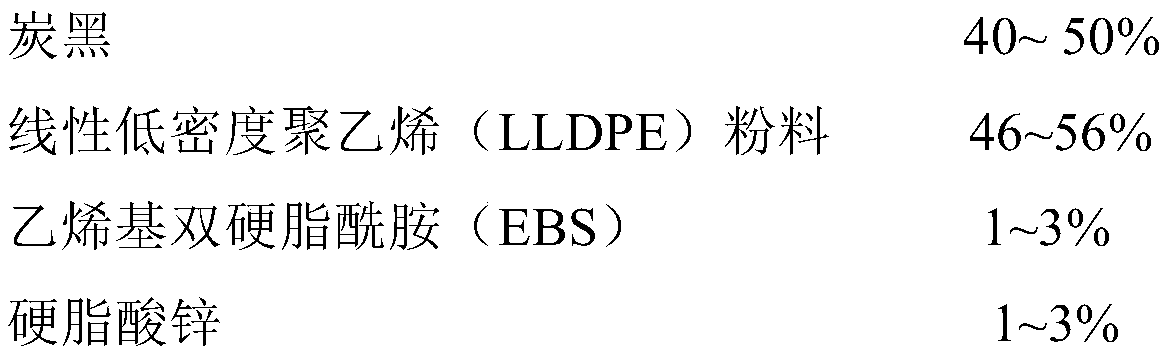

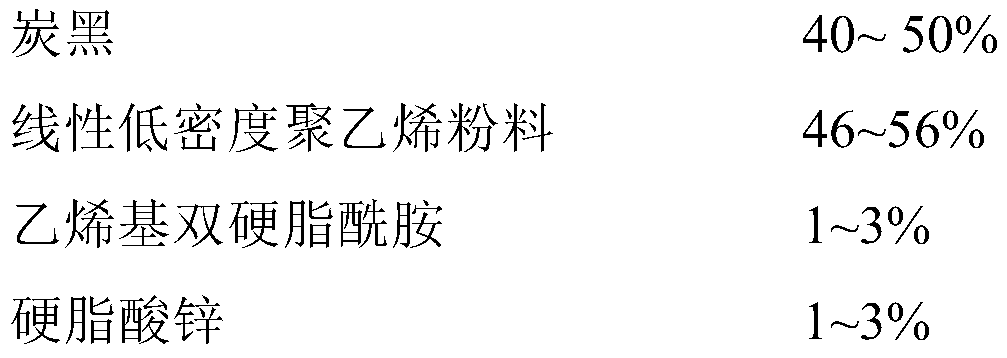

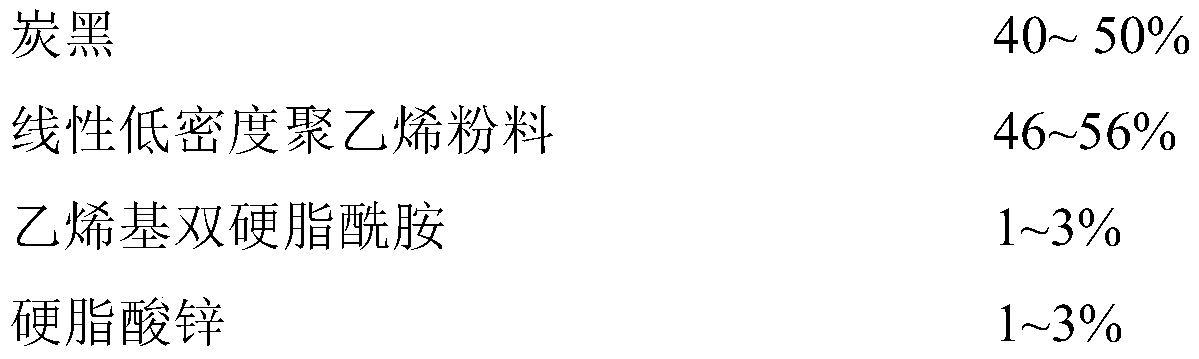

[0039] 46.0g of carbon black (average primary particle size of 21nm, oil absorption value of 55mL / 100g), 50.0g of linear low density polyethylene powder (melt index of 50g / 10min, recorded as MI50), 2.0g of vinyl Bis stearamide (EBS) and 2.0g of zinc stearate were added to a heating kneader, and mixed for 40 minutes at a heating temperature of 130°C and a rotating speed of 30r / min, and then entered into a double kneader with an aspect ratio of 48:1. Screw extruder, extrusion temperature: 150°C, 160°C, 170°C, 180°C, 190°C, head temperature 180°C, host speed 260r / min, cooled, dried, pelletized and packaged after extrusion Odorless black masterbatch.

[0040] The obtained black masterbatch is added into the polyamide, the amount of the black masterbatch is 3% of the weight of the polyamide, mixed and then extruded to obtain the black polyamide.

[0041] According to ISO527, ISO180, ISO178 standards, the test results show that compared with the original polyamide, the tensile stre...

Embodiment 2

[0043] 40.0g of carbon black (average primary particle size is 21nm, oil absorption value is 55mL / 100g), 56.0g of linear low density polyethylene powder (MI50), 1.0g of EBS and 3.0g of zinc stearate are added to heat Type kneader, at a heating temperature of 130°C and a speed of 40r / min, mix for 30 minutes, and then enter a twin-screw extruder with a length-to-diameter ratio of 48:1, extrusion temperature: 150°C, 160°C, 170°C , 180°C, 190°C, head temperature 180°C, host speed 260r / min, after extrusion, cooling, drying, pelletizing, and packaging into odorless black masterbatch.

[0044] Add the obtained black masterbatch into ABS, the consumption of black masterbatch is 3% of ABS weight, mix and extrude to obtain black ABS.

[0045] Tested according to ISO527, ISO180, ISO178, ISO75 standards, the test results show that compared with the original ABS, the tensile strength of the obtained black ABS is reduced by 10%, the elongation at break is increased by 5%, the impact strengt...

Embodiment 3

[0047] 50.0g of carbon black (average primary particle diameter is 21nm, oil absorption value is 55mL / 100g), 46.0g of linear low density polyethylene powder (MI50), 3.0g of EBS and 1.0g of zinc stearate are added to heat Type kneader, at a heating temperature of 130°C and a rotating speed of 20r / min, mix for 50 minutes, and then enter a twin-screw extruder with a length-to-diameter ratio of 48:1, extrusion temperature: 150°C, 160°C, 170°C , 180 ℃, 190 ℃, head temperature 180 ℃, host speed 260r / min, after cooling, drying, dicing, packaging into odorless black masterbatch.

[0048] Add the obtained black masterbatch into polycarbonate (PC), the consumption of the black masterbatch is 3% of PC weight, mix and extrude to obtain black PC.

[0049] Tested according to ISO527, ISO180, ISO178 standards, the test results show that compared with the original PC, the tensile strength of the obtained black PC is reduced by 2%, the elongation at break is reduced by 36%, the impact strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com