Color sealing material for edge of card base and manufacturing method thereof

A sealing material and color technology, applied in the field of materials, can solve the problems that affect the use of card products, affect the overall appearance of card base products, and delaminate between layers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

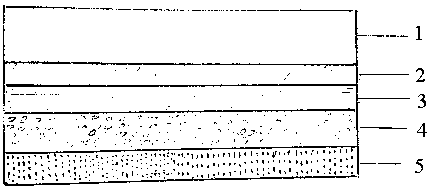

[0019] The structure of the card base edge color seal material is as figure 1 As shown, in order from bottom to top are base film layer 1, separation adhesive layer 2, sealing protection layer 3, color ribbon layer 4, adhesive adhesive layer 5, and the color sealing material at the edge of the card base can be as follows Make:

[0020] Polyethylene terephthalate is casted, stretched to form a base film; 36% n-butyl acrylate, 14wt% hydroxyethyl methacrylate, 28wt% propylene oxide butyl ether, 7wt% triethanolamine After 15wt% ammonium bicarbonate is dissolved in propanol, stir evenly, then heat in a water bath to evaporate the solvent to form a jelly, and coat the above-mentioned jel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com