Burner-based GPF (Gasoline Particulate Filter) rapid ash content accumulation aging test device

A technology of aging test and burner, which is applied in the testing of machine/structural components, measuring devices, internal combustion engine testing, etc. It can solve the problems of reducing fuel economy and particulate matter collection efficiency, shorten the test cycle, reduce time cost, The effect of shortening the test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

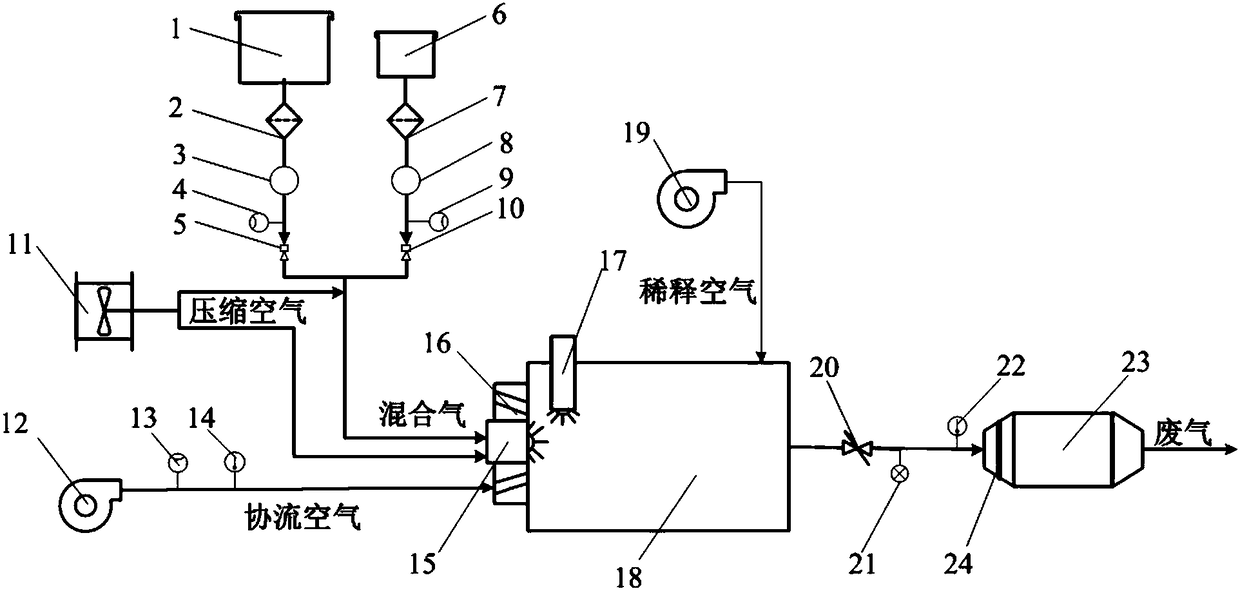

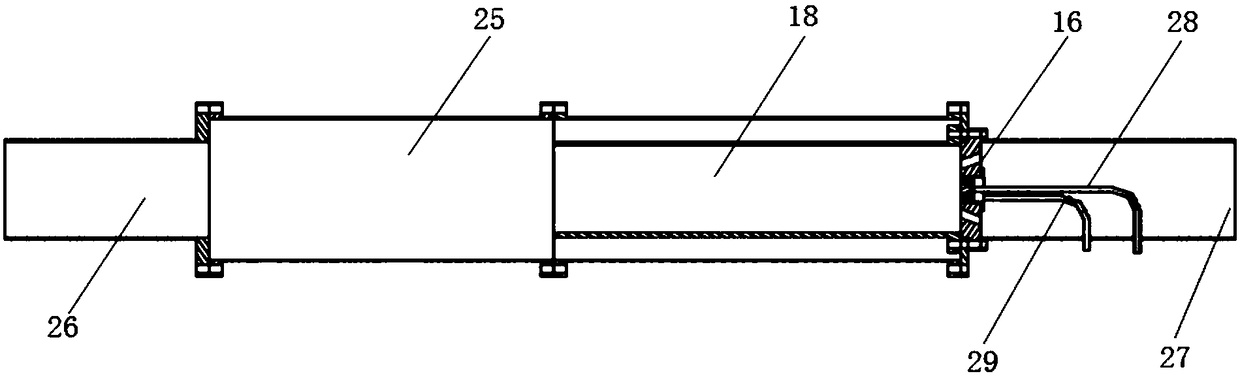

[0022] A burner-based GPF rapid ash accumulation aging test device, such as figure 1 As shown, it includes an oil inlet unit for providing engine oil and gasoline, a compressed air unit, a co-flow air unit, a dilution air unit, a burner unit, and a GPF unit, wherein the burner unit includes a burner cavity 18, which is located in the burner cavity The spark plug 17 on the body 18, the combustion disc 16 and the air-assisted atomizing nozzle 15 located at the inlet end of the burner cavity 18, such as figure 2 As shown, the oil inlet unit, the compressed air unit and the co-flow air unit are all connected to the inlet end of the burner cavity 18 through pipelines, the rear end of the burner cavity 18 is provided with a mixing chamber 25, and the dilution air unit includes a dilution fan 19, It is connected to the mixing chamber 25, and the rear end of the mixing chamber 25 is connected to the GPF unit through the exhaust pipeline 26. The oil inlet unit includes a gasoline int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com