Finite element analysis method of curved stiffened plate in high-temperature environment

A high-temperature environment and analysis method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of low modeling efficiency and inability to realize common use of thick and thin plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

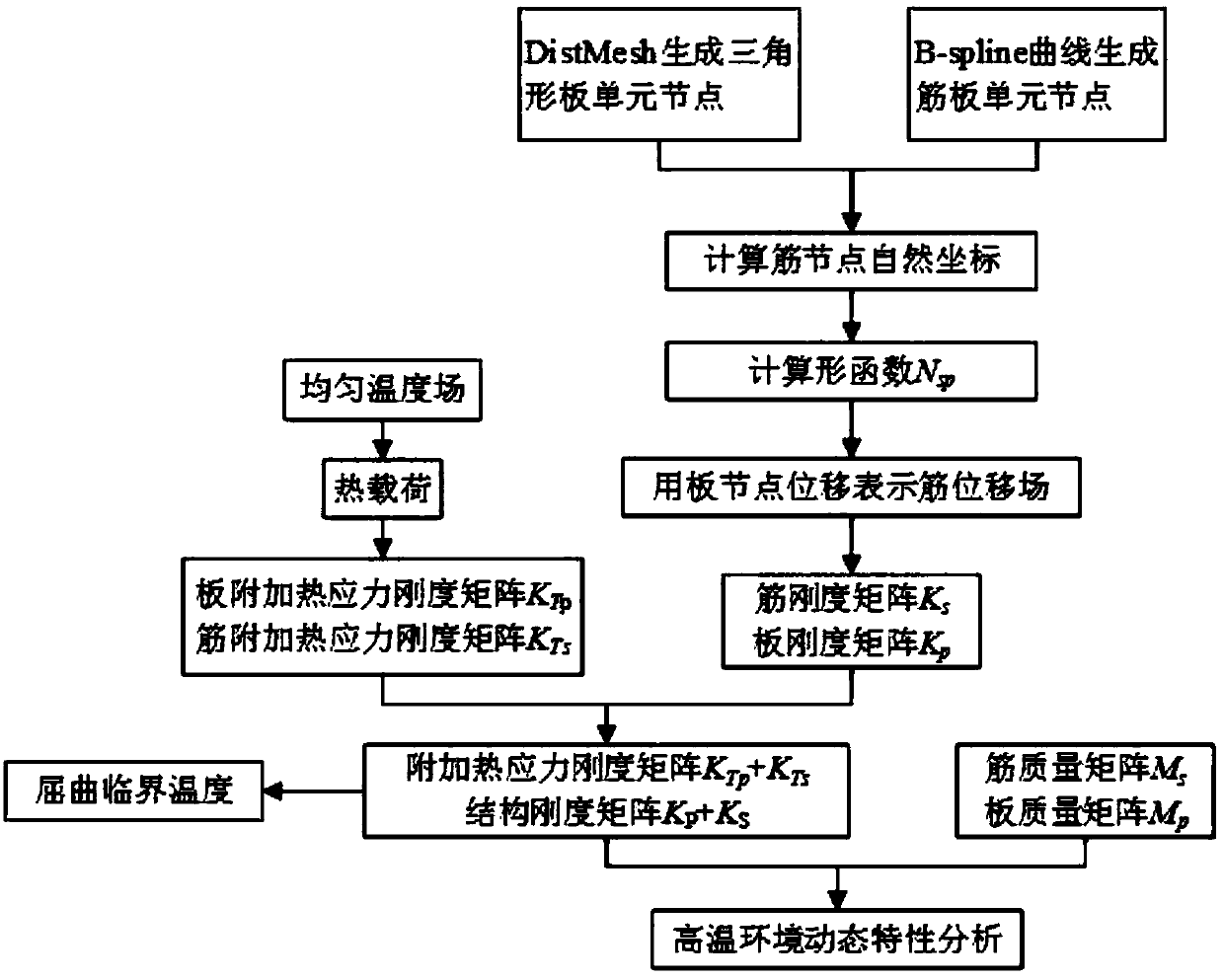

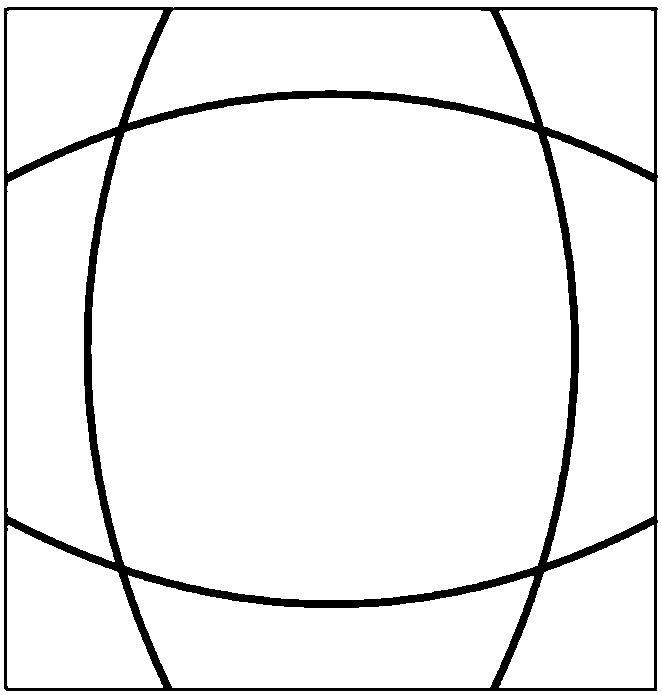

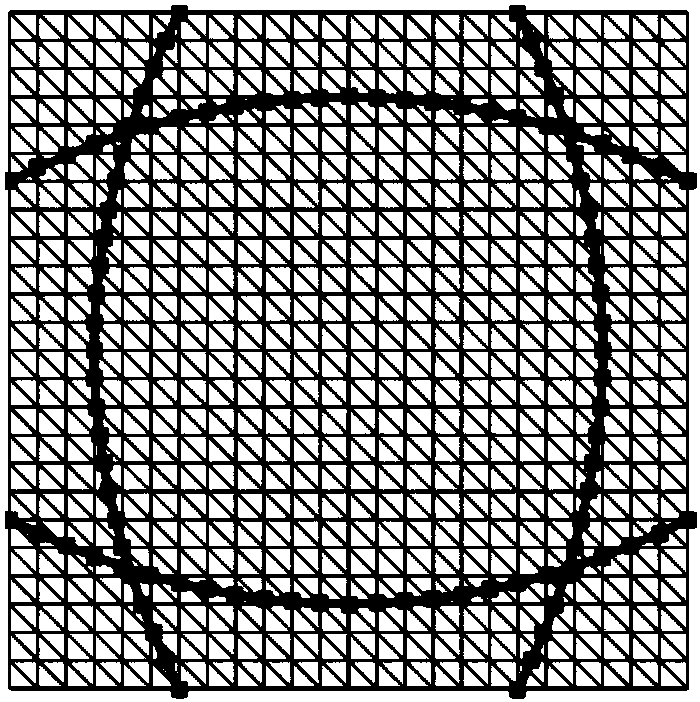

[0055] Such as figure 1 , a finite element analysis method for a curved stiffened plate under a high-temperature environment of the present invention mainly includes the following steps:

[0056] Step 1, using the deflection field expressed by linear interpolation combined with the DST-BK unit to obtain the stiffness matrix K of the plate element that only considers the influence of temperature changes on the material p and plate element mass matrix M p ;

[0057] Step 2: At the rib-slab interface, according to the rib-slab displacement coupling condition, the rib node displacement is expressed by the plate node displacement, and the stiffness matrix K of the rib element after the rib-slab displacement coordination is obtained s and rib element mass matrix M s ;

[0058] Step 3, the uniform temperature field is equivalent to a thermal loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com