Piston for use in engine cylinder and piston engine

A piston engine and engine cylinder technology, applied to engine components, machines/engines, pistons, etc., can solve the problems of reducing engine power and thermal efficiency, excessive exhaust pollutant emissions, and insufficient fuel combustion, etc., to improve power and thermal efficiency , reasonable spatial distribution and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

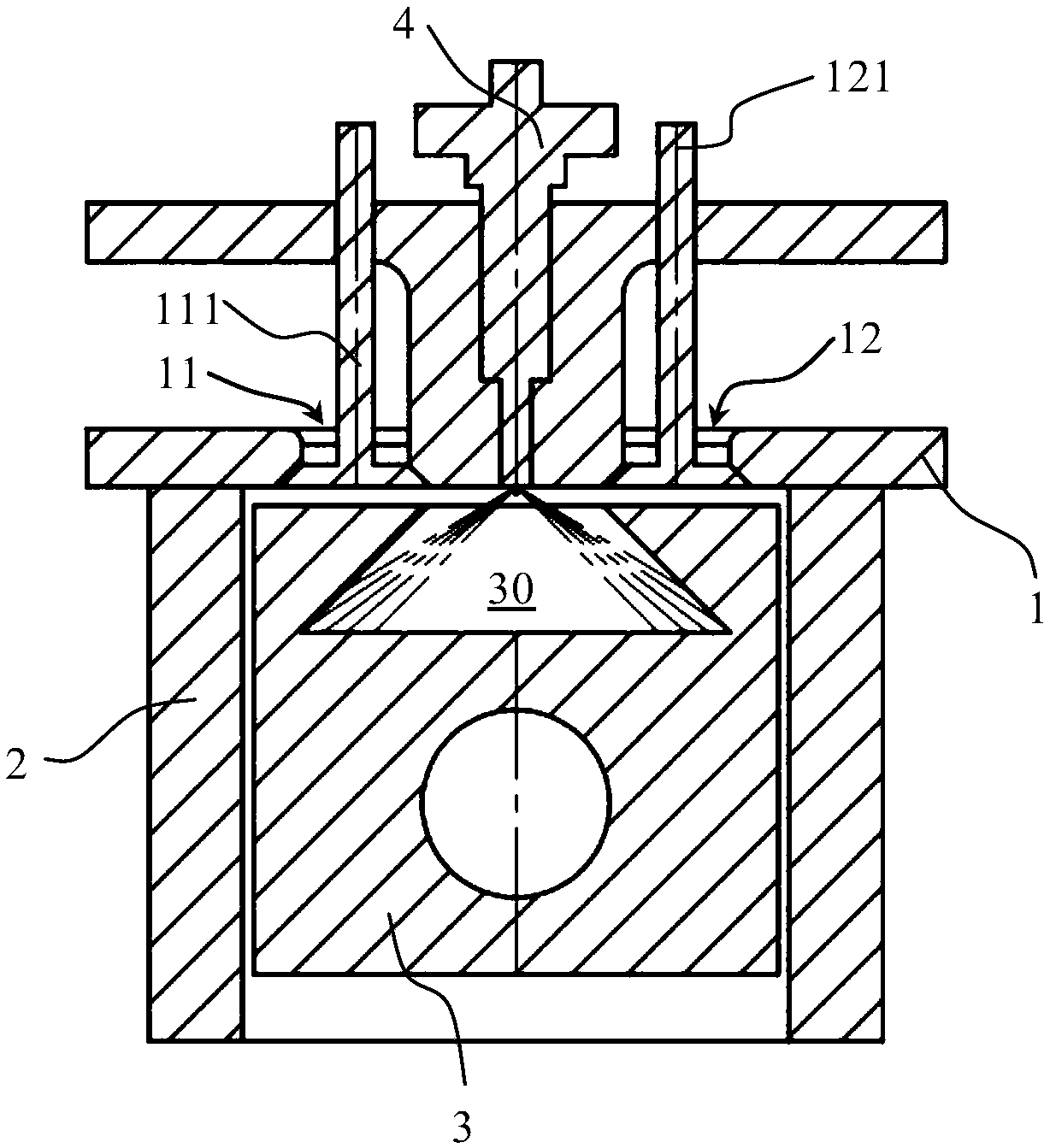

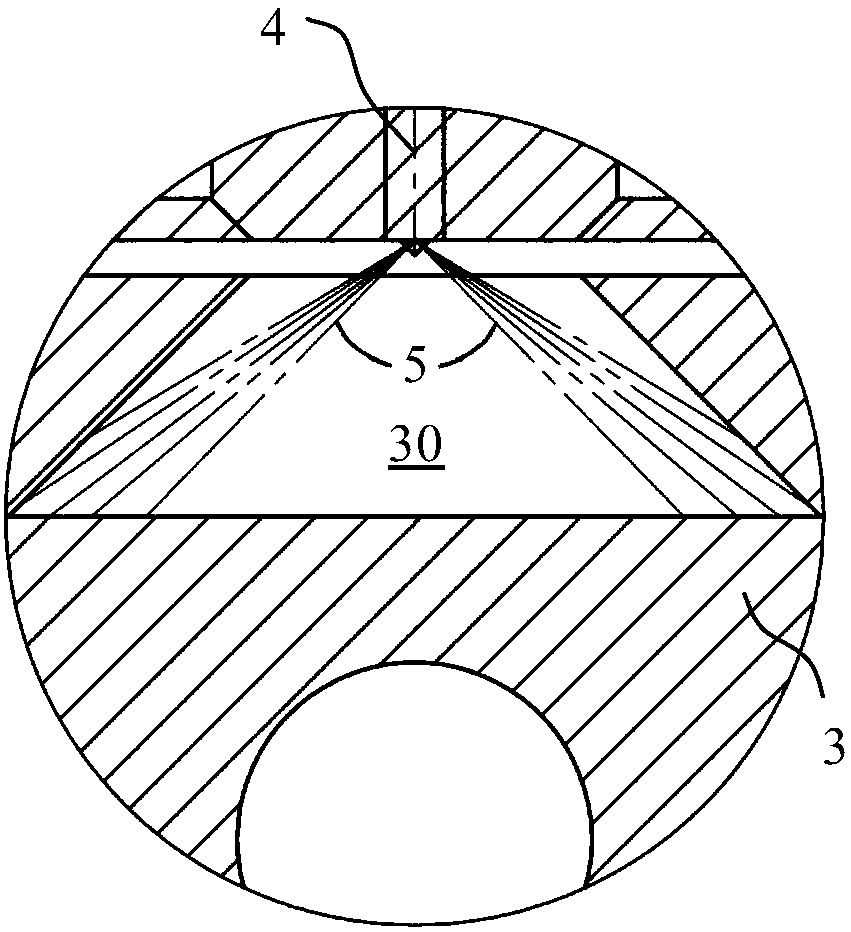

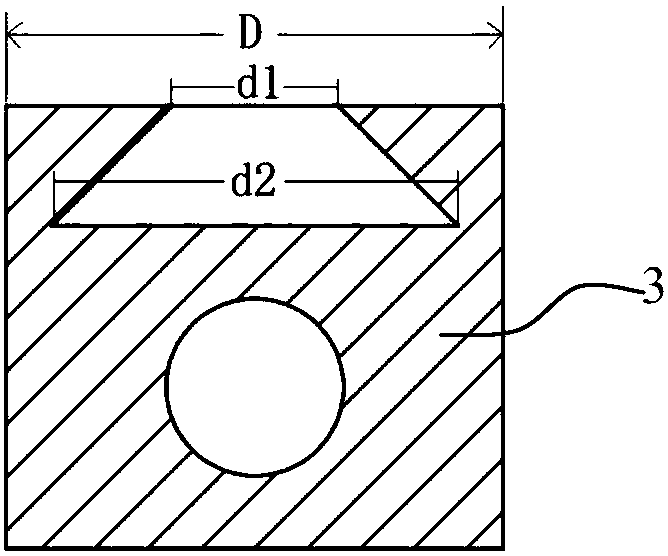

[0018] see Figure 1 ~ Figure 3 , which is a piston engine of the present invention, comprising a cylinder and a fuel injector 4, the combustion chamber of the cylinder is surrounded by a cylinder wall 2, a cylinder head 1 and a piston 3 that is sleeved on the cylinder wall, and the fuel injector 4 is located in the cylinder The middle part of the cover 1 is facing the outlet of the notch on the top of the piston 3. The cylinder head is provided with an air inlet 11, an inlet valve 111, an exhaust port 12, and an exhaust valve 121. The oil beam ejected from the injector is Cone angle 5 is formed. The top surface of the piston 3 is inwardly recessed into a notch 30, which is a truncated cone. On its cross-sectional view, it can be seen that the notch is a symmetrical trapezoid, and the bottom edge of this trapezoid and the included angle 6( Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com