Spraying-angle-gradual-changing-type tool washing device with disinfection function

A spray angle and water washing device technology, which is applied in the field of kitchen utensils, can solve the problems of bacteria, tool oxidation, and unsightly appearance, and achieve the effects of easy rotation, improved cleaning efficiency, and enhanced jet impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

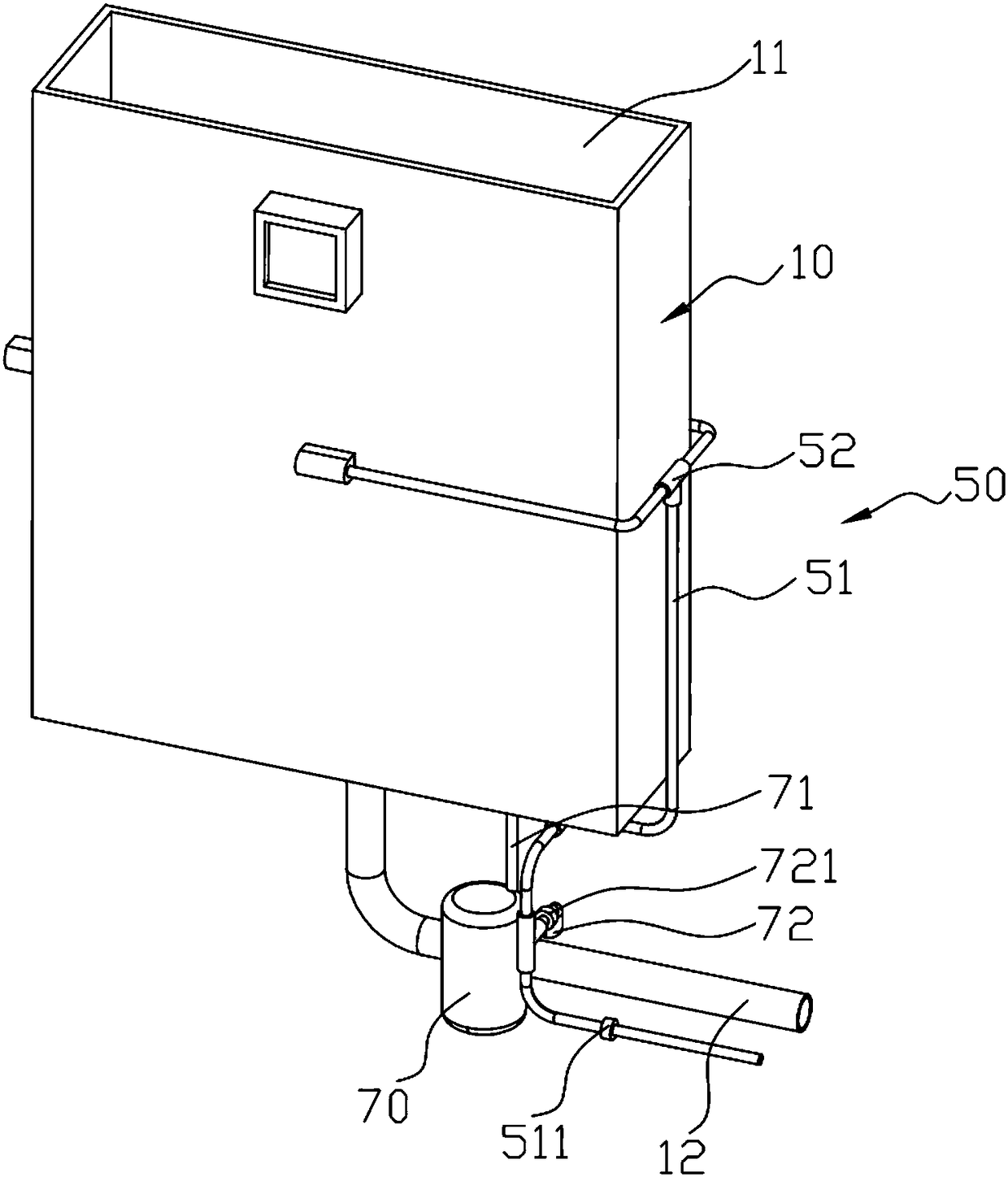

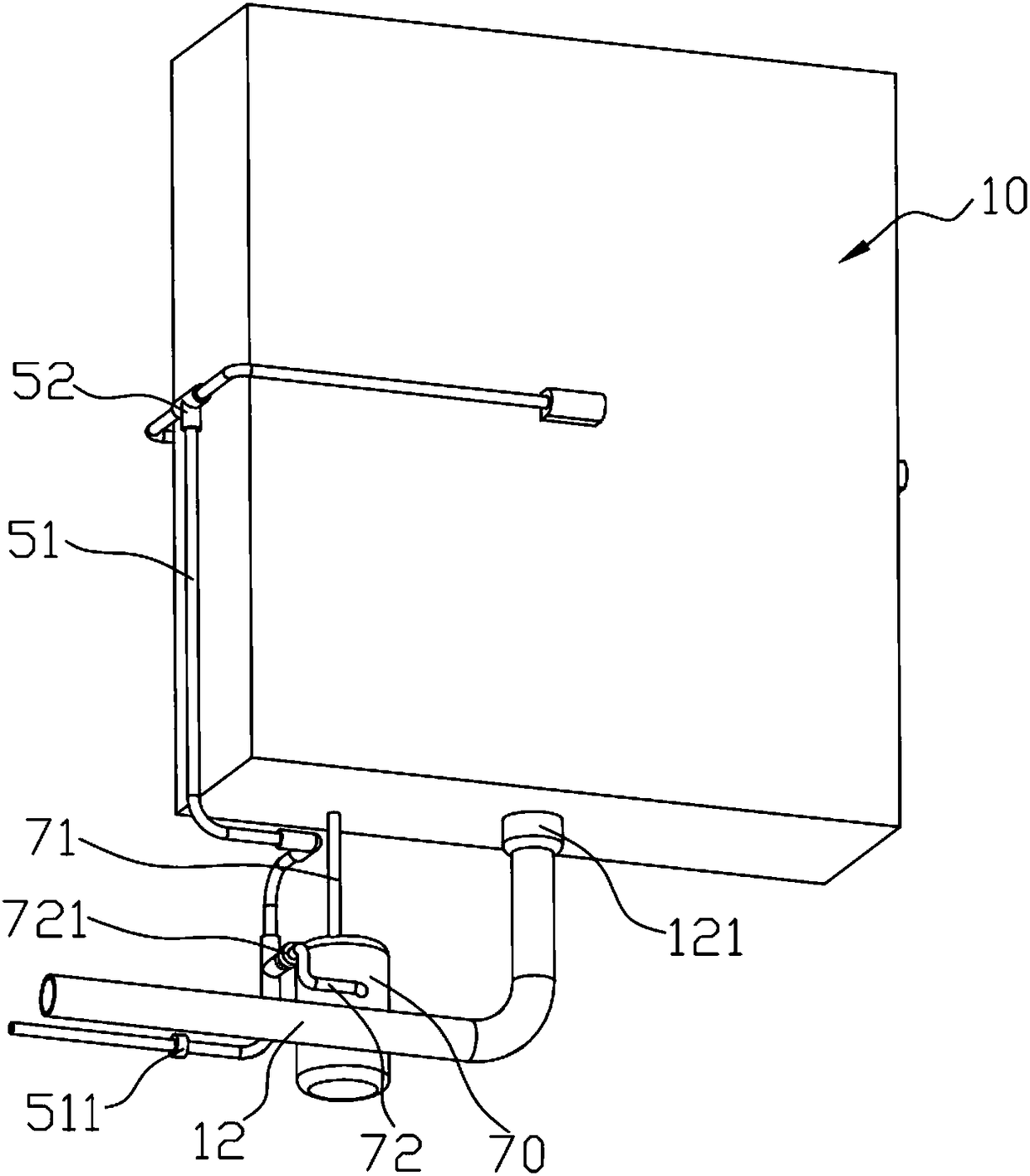

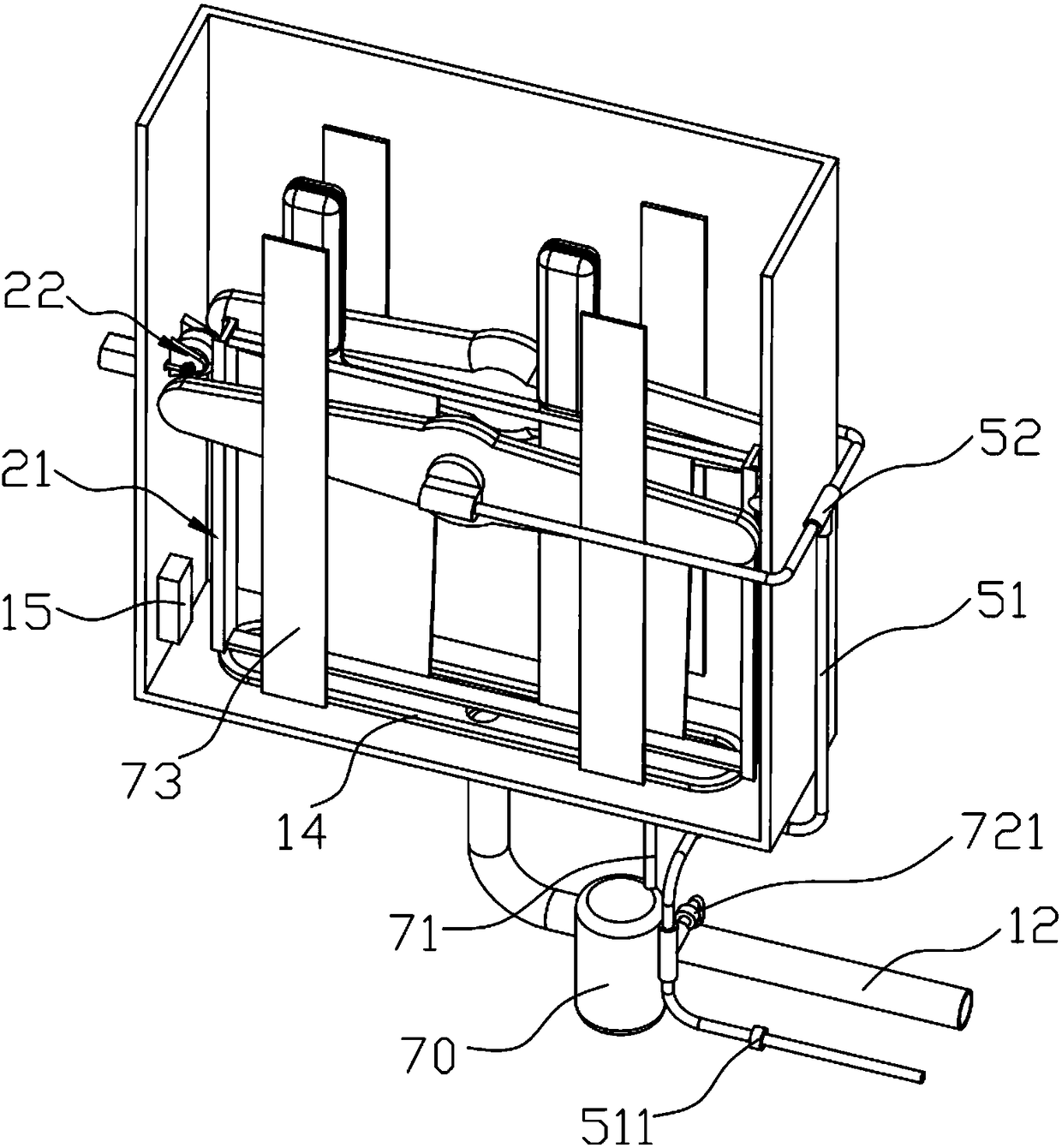

[0031] Such as Figure 1 to Figure 14 As shown, the present invention provides a knife washing device with a disinfection function and a gradual change in spray angle, including: a box body 10, which is a hollow cavity; a knife holder 21, which is used to carry the knife 20 and is arranged in the box In the hollow cavity of the body 10; at least one spray arm 30, which is located at the side of the tool holder 21 and has a guide channel 33 in the spray arm 30, and one side of the spray arm 30 is connected with the The water-washing pipeline unit 50 connected with the guide channel 33, the other side of the spray arm 30 is provided with several spray holes 31 communicated with the guide channel 33; several nozzles 40 are communicated one by one Arranged in the spray hole 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com