Aripiprazole sustained-release microsphere and preparation method thereof

A technology of aripiprazole and sustained-release microspheres, which is applied in the direction of pharmaceutical formulations, medical preparations with no active ingredients, and medical preparations containing active ingredients. Slowness and other problems, to achieve the effect of reducing patient pain, obvious pain, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Aripiprazole 50g and polylactide-glycolide copolymer 20g are mixed, wherein polylactide-glycolide copolymer 0.2dL / g, distribution coefficient 1.5%, weight average molecular weight is 25000, polylactide and glycolide The molar ratio of lactide is 50:50, add 400g (301.9ml) of dichloromethane and mix, heat at 55°C, and shake to dissolve. At the same time, prepare 62L of 1% PVA solution, add sodium hydroxide to adjust the pH to 10, control the temperature at 12°C, and use a high-speed emulsifier or static mixer to disperse the solvent in the external PVA solution at a speed of 3000rpm. After solidification for 3 hours, the microspheres were harvested by centrifugation and freeze-dried.

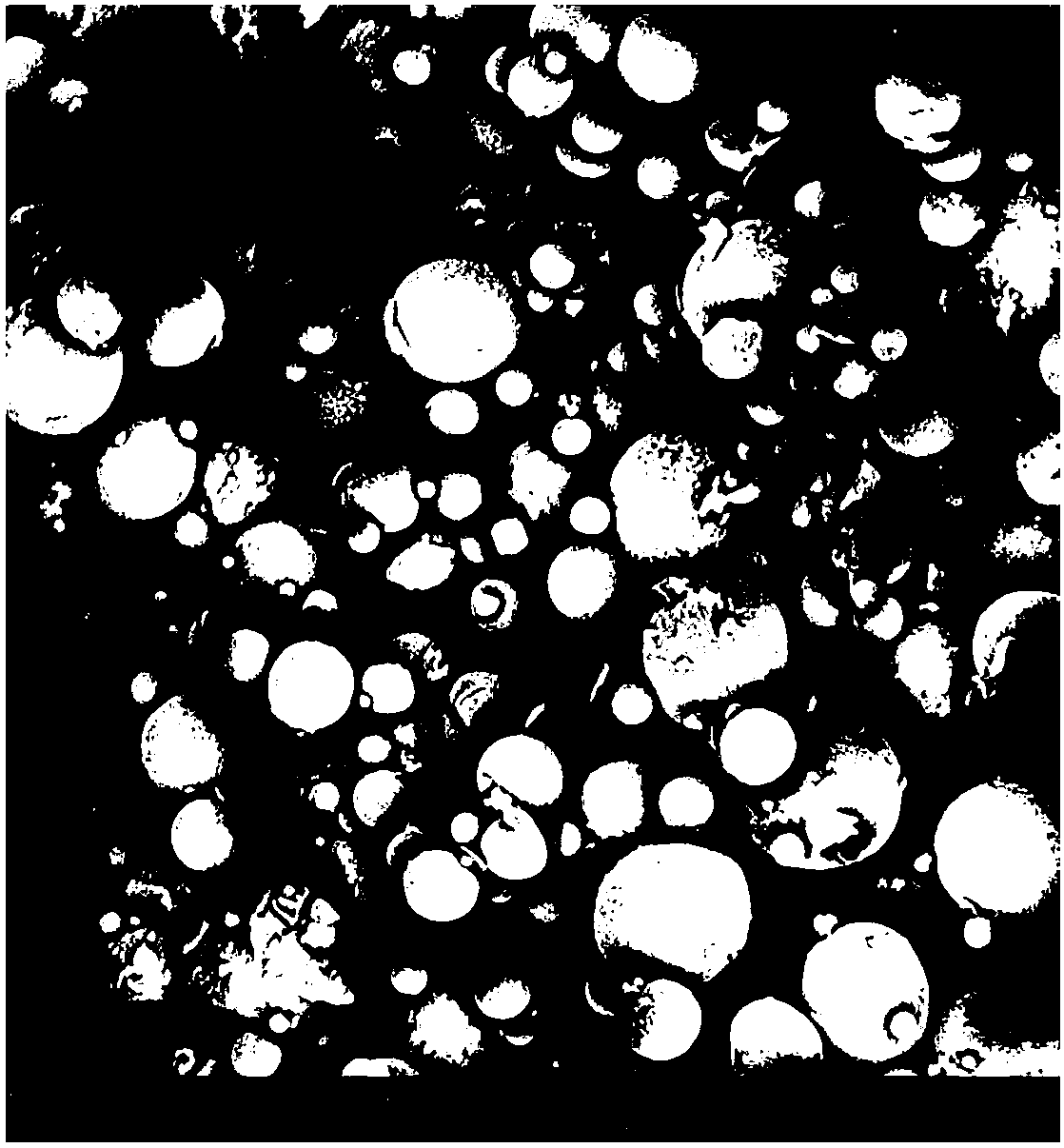

[0082] Conclusion: The drug loading of the microspheres is 71%, the yield is 92%, the spheroidization is good, the surface of the microspheres is smooth and complete, and the scanning electron microscope image of the obtained microsphere samples is as follows figure 1 shown. Dissolved by...

Embodiment 2

[0084]Aripiprazole 50g and polylactide-glycolide copolymer 20g are mixed, wherein polylactide-glycolide copolymer 0.55dL / g, distribution coefficient 3.0%, weight average molecular weight is 35000, polylactide and glycolide The molar ratio of lactide is 50:50, add 400g of dichloromethane and mix, heat at 55°C, and shake to dissolve. At the same time, prepare 62L of 1% PVA solution, add sodium hydroxide to adjust the pH to 10, control the temperature at 12°C, and use a high-speed emulsifier or static mixer to disperse the solvent in the external PVA solution at a speed of 3000rpm. After solidification for 3 hours, the microspheres were harvested by centrifugation and freeze-dried.

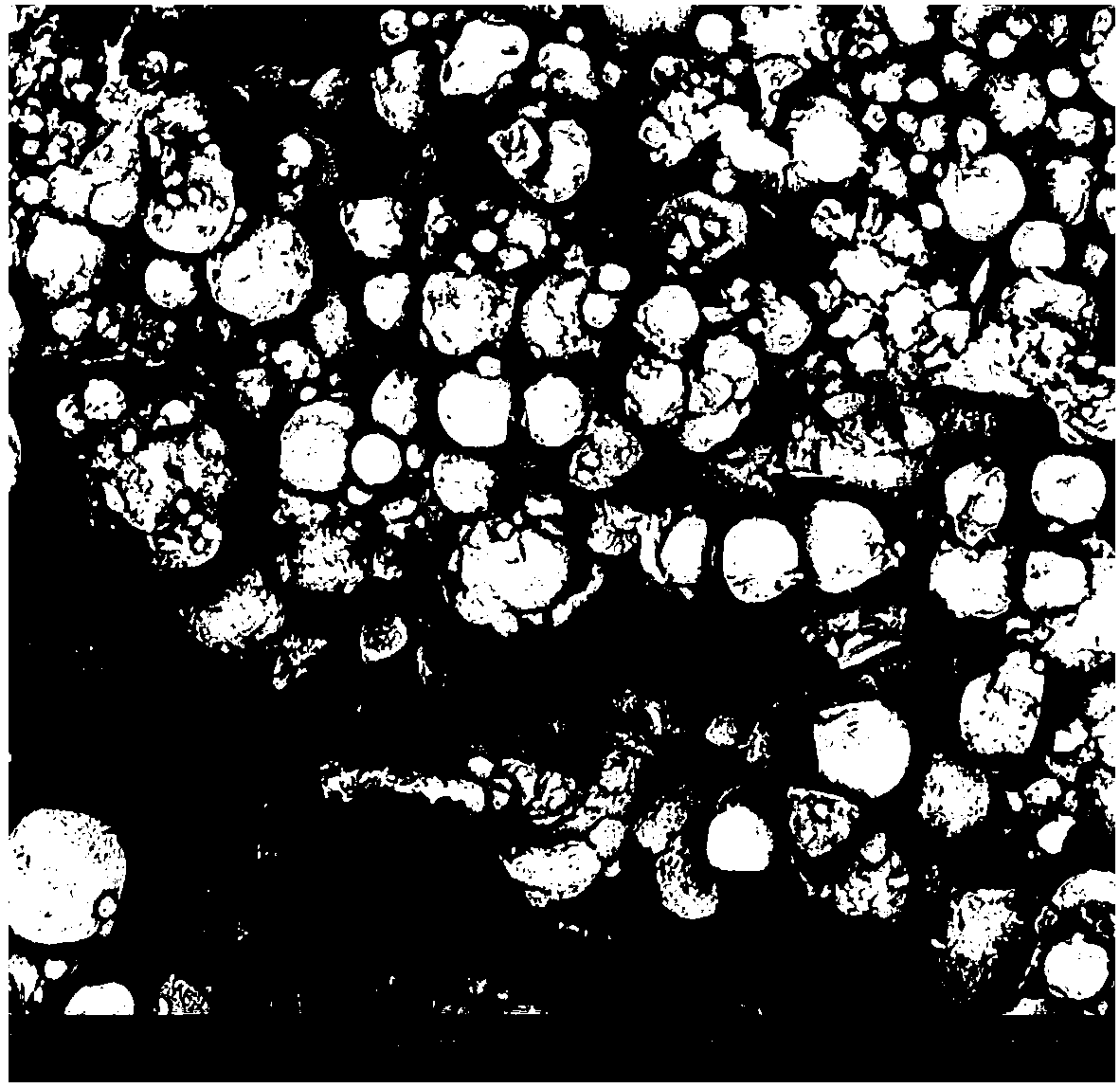

[0085] Conclusion: The drug loading of the microspheres is 70%, the yield is 87%, the spheroidization is good, the surface of the microspheres is smooth and complete, and the scanning electron microscope image of the obtained microsphere samples is as follows figure 2 shown. Dissolved by 10% aceti...

Embodiment 3

[0087] Aripiprazole 50g and polylactide-glycolide copolymer 20g are mixed, wherein polylactide-glycolide copolymer 0.6dL / g, distribution coefficient 2.0%, weight average molecular weight is 75000, polylactide and glycolide The molar ratio of lactide is 75:25, add 400g of dichloromethane and mix, heat at 55°C, shake to dissolve. At the same time, prepare 62L of 1% PVA solution, add sodium hydroxide to adjust the pH to 10, control the temperature at 12°C, and use a high-speed emulsifier or static mixer to disperse the solvent in the external PVA solution at a speed of 3000rpm. After solidification for 3 hours, the microspheres were harvested by centrifugation and freeze-dried.

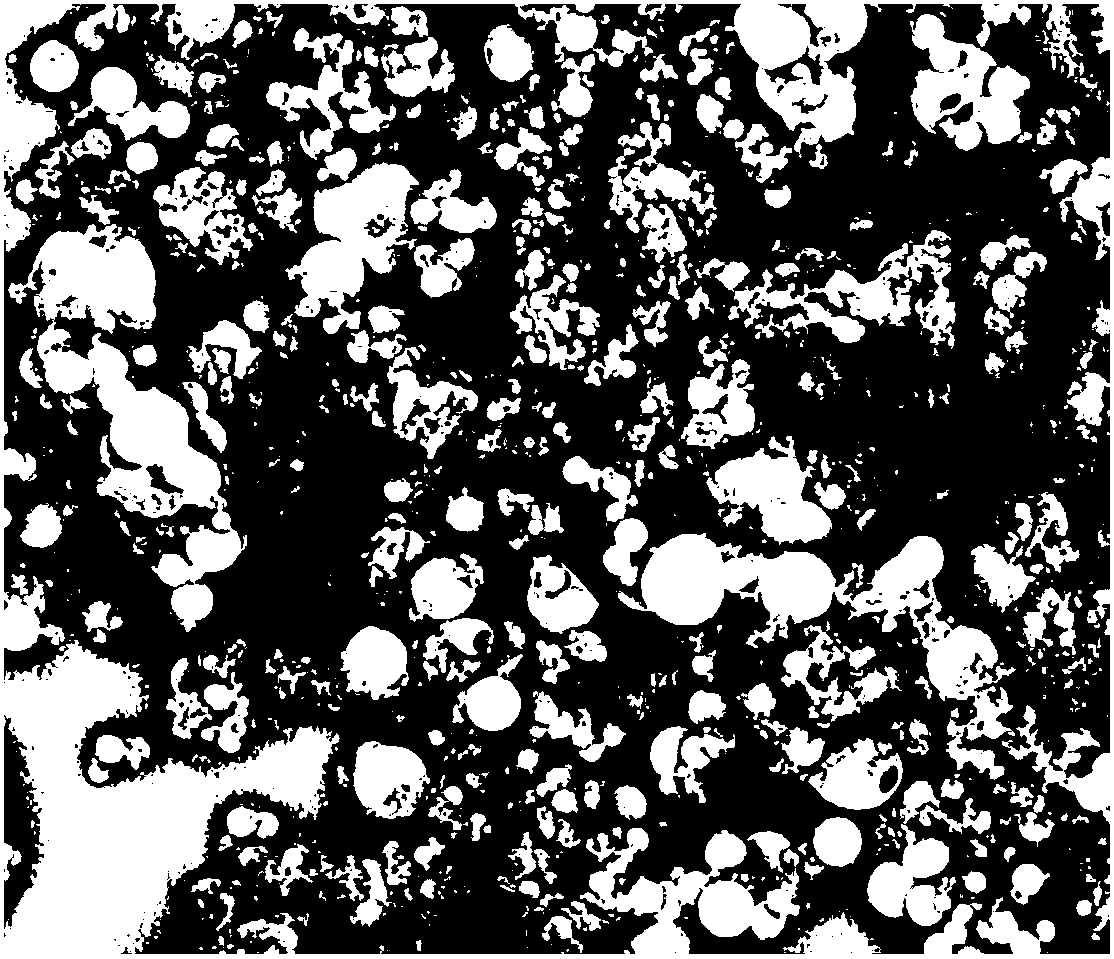

[0088] Conclusion: The drug loading capacity of the microspheres is 68%, and the yield is 80%. Only a few of the harvested samples form spheres, most of the samples form irregular particles, and the fluidity is poor. The scanning electron microscope image of the obtained microsphere samples is as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com