Spinning tool for barrel with inner circumferential rib and forming method

A technology of circumferential rib and inner spinning, which is used in the field of spinning tooling and forming of cylinders with inner circumferential ribs, which can solve the problems of poor dimensional accuracy and consistency, difficult to control the amount of expansion, and achieve good forming accuracy of parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the prior art, when the members with inner circumferential ribs are formed by external rotation, there are disadvantages that it is difficult to control the amount of diameter expansion, and the technical indicators such as shape and size are difficult to meet. In addition, in order to be able to remove the parts from the mold, the external rotation forming mold It is necessary to adopt a resolution mold, which brings problems such as high mold cost and low use efficiency. In order to solve the above-mentioned defects, an embodiment of the present invention provides a spinning tool and forming method for a cylindrical body with inner circumferential ribs.

[0041] In order to solve the above defects, the main ideas of the embodiments of the present invention are:

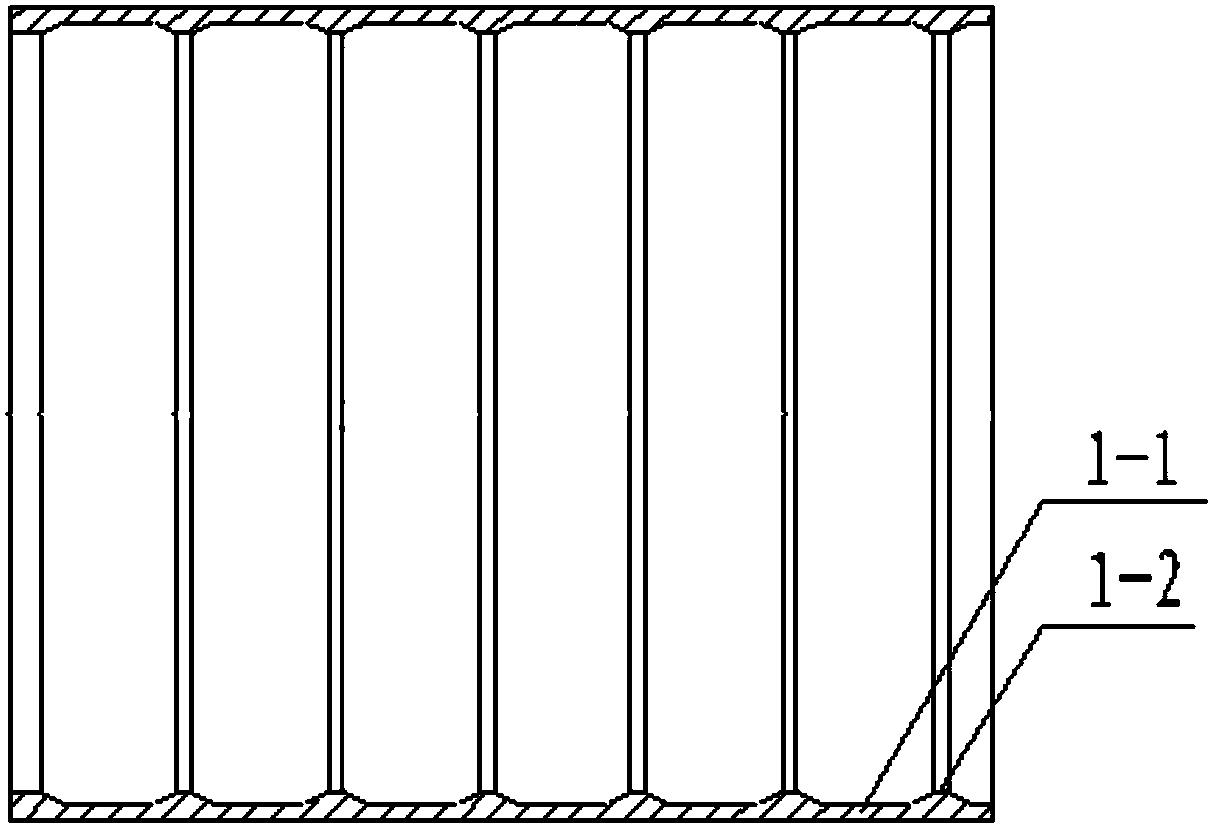

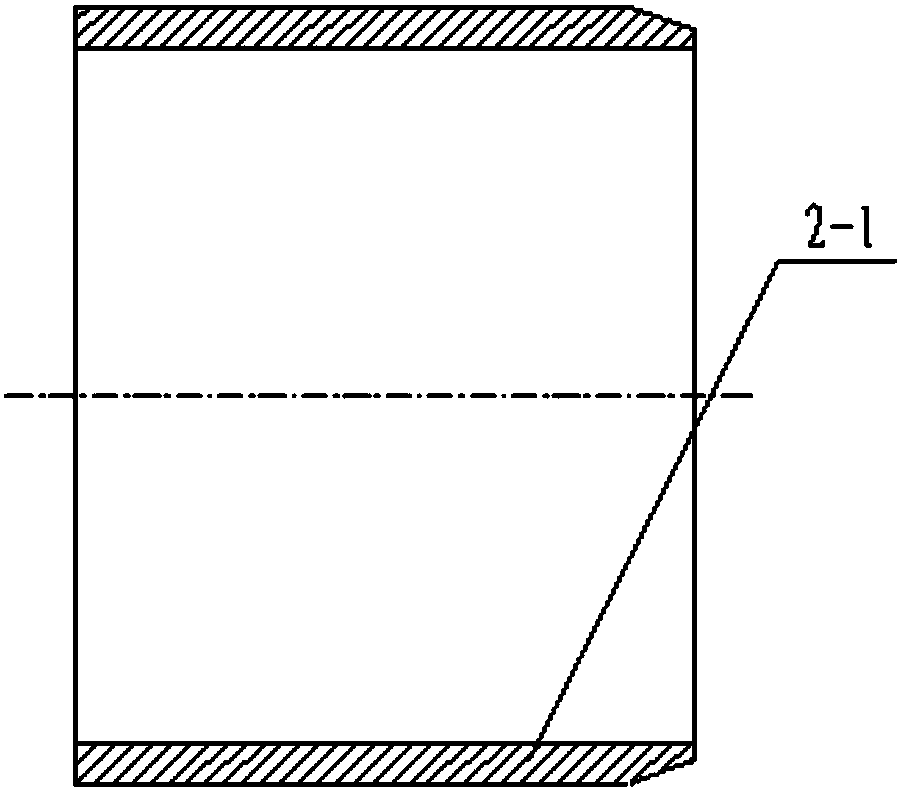

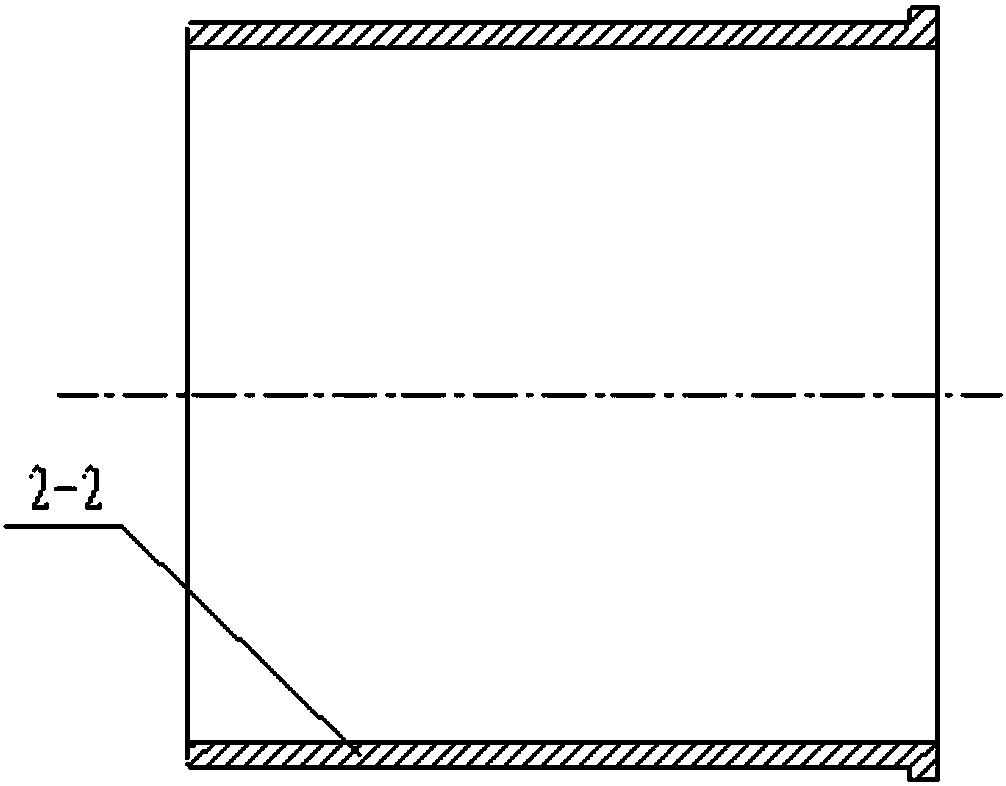

[0042] In the embodiment of the present invention, the spinning tooling of the cylinder body with inner circumferential ribs is carried out on a machine tool, and the tooling includes external rotation too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com