Thread producing machine

A thread processing and frame technology, which is applied to metal processing machinery parts, metal processing equipment, thread cutting machines, etc., can solve the problems of high maintenance cost, slow process, and inconvenient switching of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

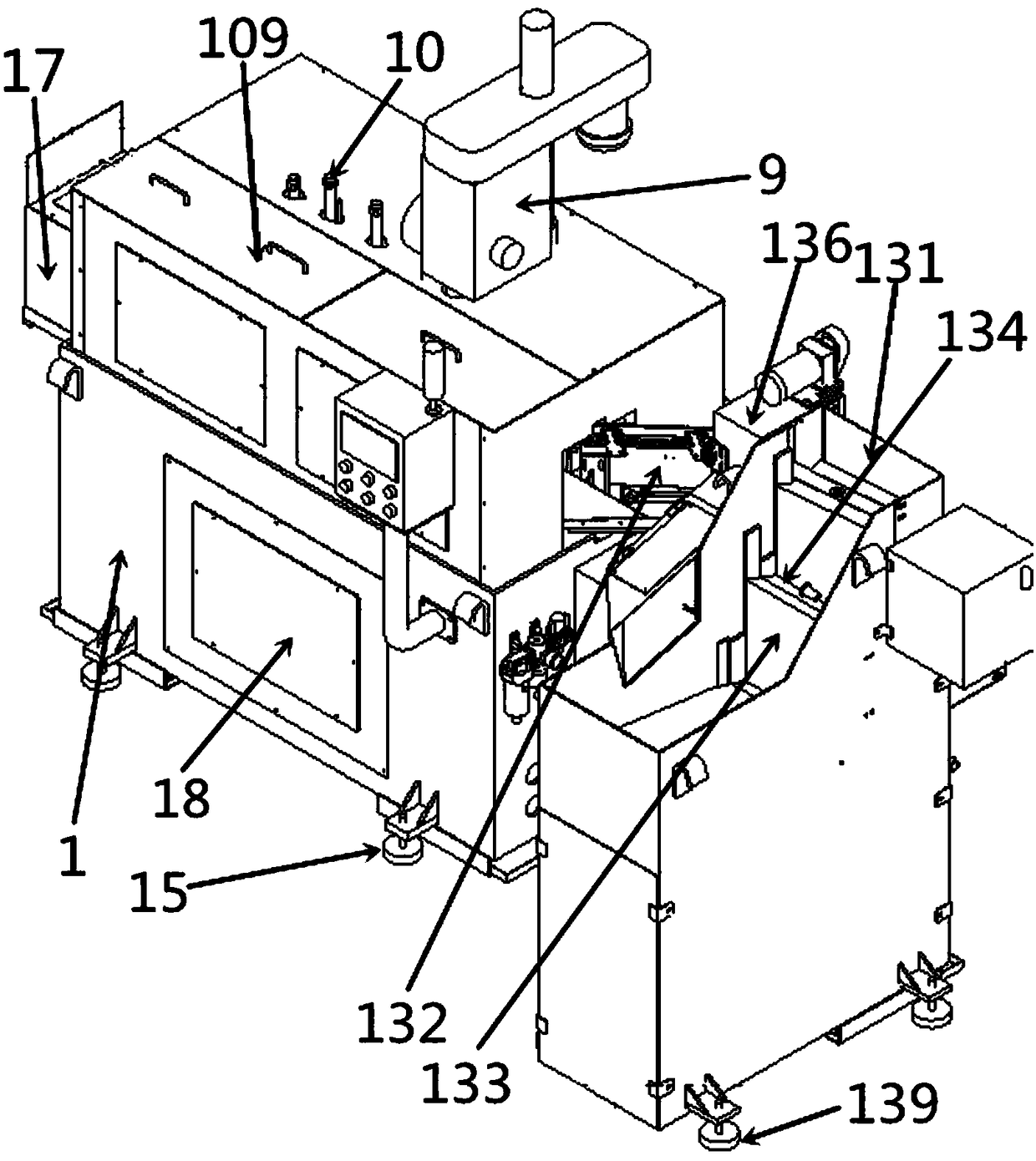

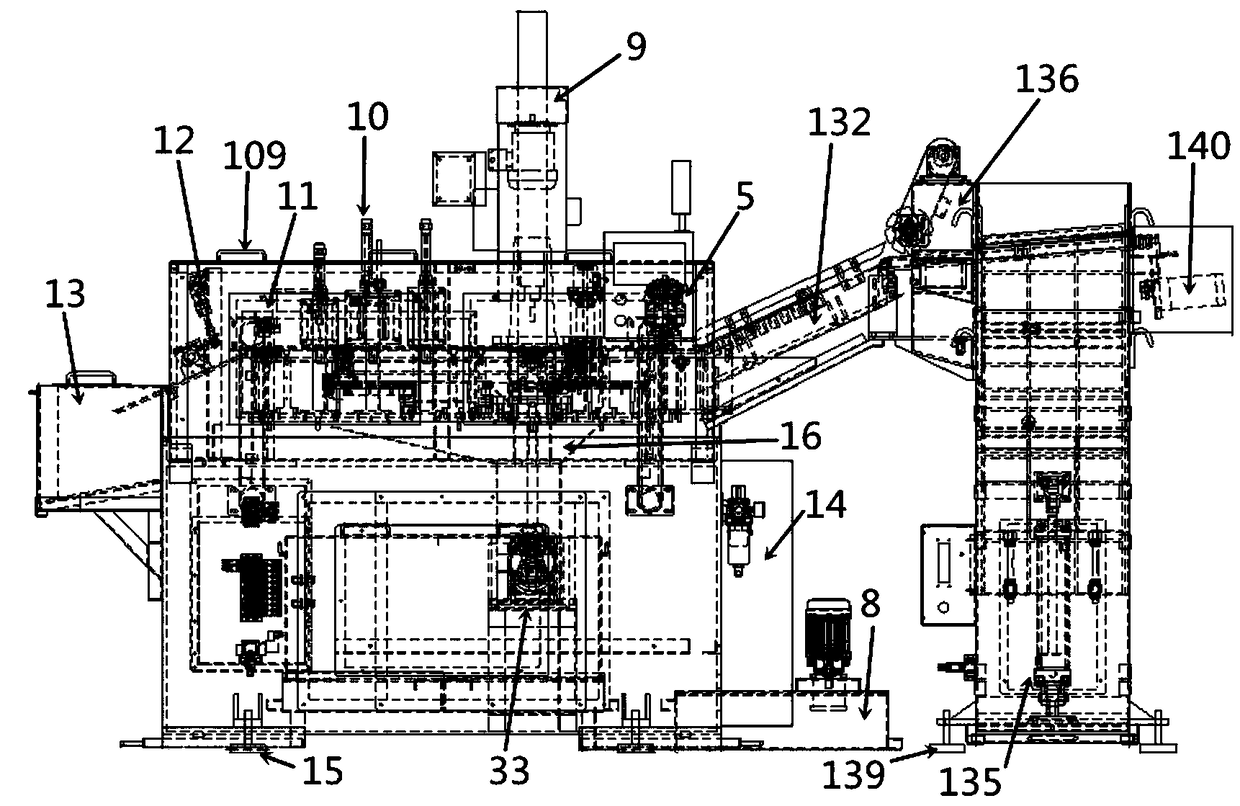

[0065] The thread processing machine is composed of a tapping host and a feeder. The tapping host and the feeder are connected by a slide mechanism, such as Figure 1-2 Shown.

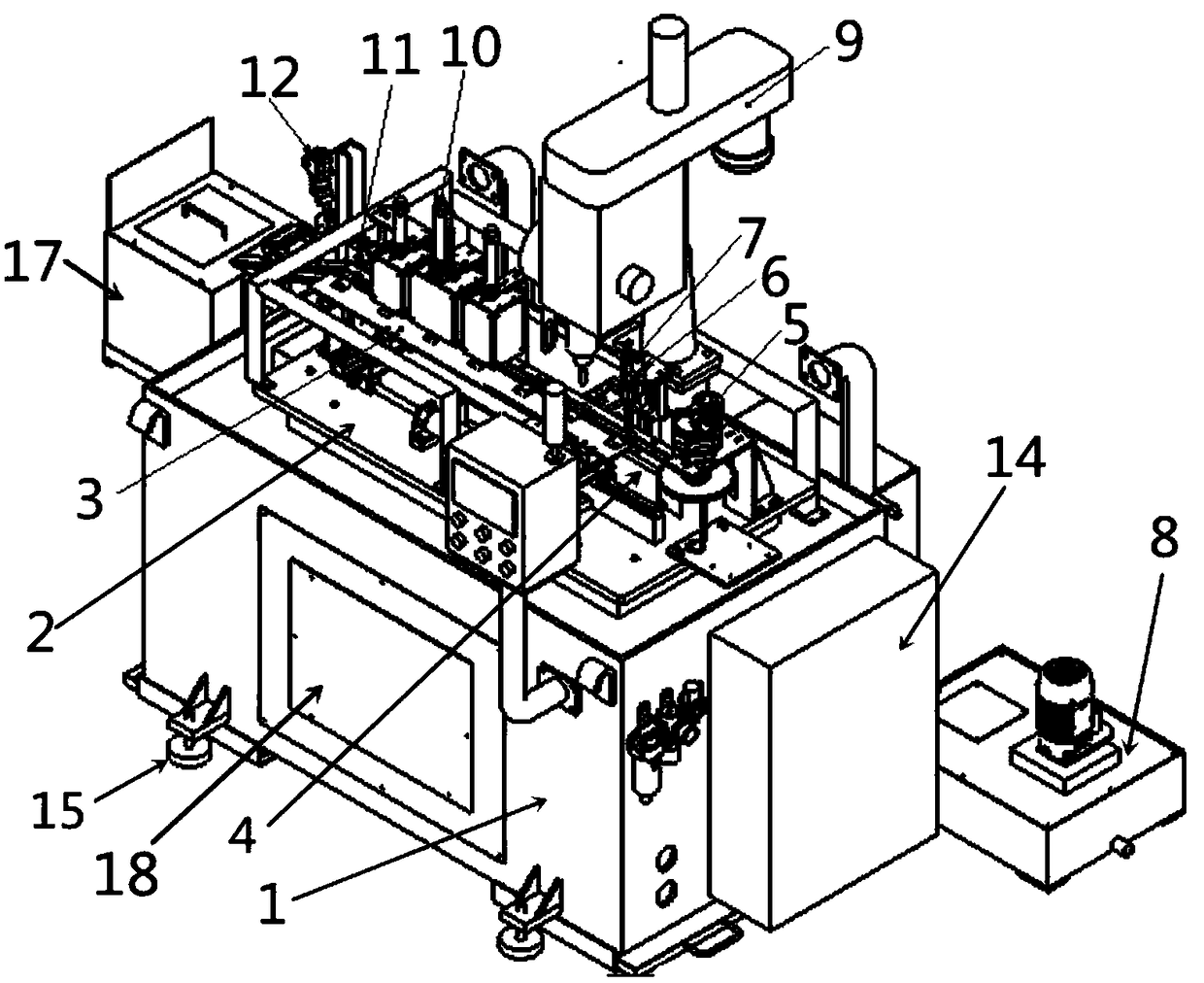

[0066] The tapping host, such as image 3 As shown, the tapping host includes a tapping machine frame 1 and a working platform 2. The working platform 2 is fixed on the tapping machine frame 1. The working platform 2 is provided with a transmission mechanism, and the transmission mechanism includes an XY conveying mechanism 3. The conveyor track 4 is in the middle of the work platform 2 with the conveyor track 4, the conveyor track 4 is responsible for planning the walking route of the workpiece, the XY transport mechanism 3 is on the side of the conveyor track 4, and the XY conveyor mechanism 4 is responsible for moving the workpiece on the conveyor track.

[0067] The conveyor track 4 is divided into a product input area, a product work area, and a product inspection and cleaning area in turn. The product i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com