Oscillation wave power generation system

A power generation system and wave energy technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve problems such as bulky volume, low conversion efficiency, complex design, etc., and achieve a small overall space volume, simple structure, and detachable. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

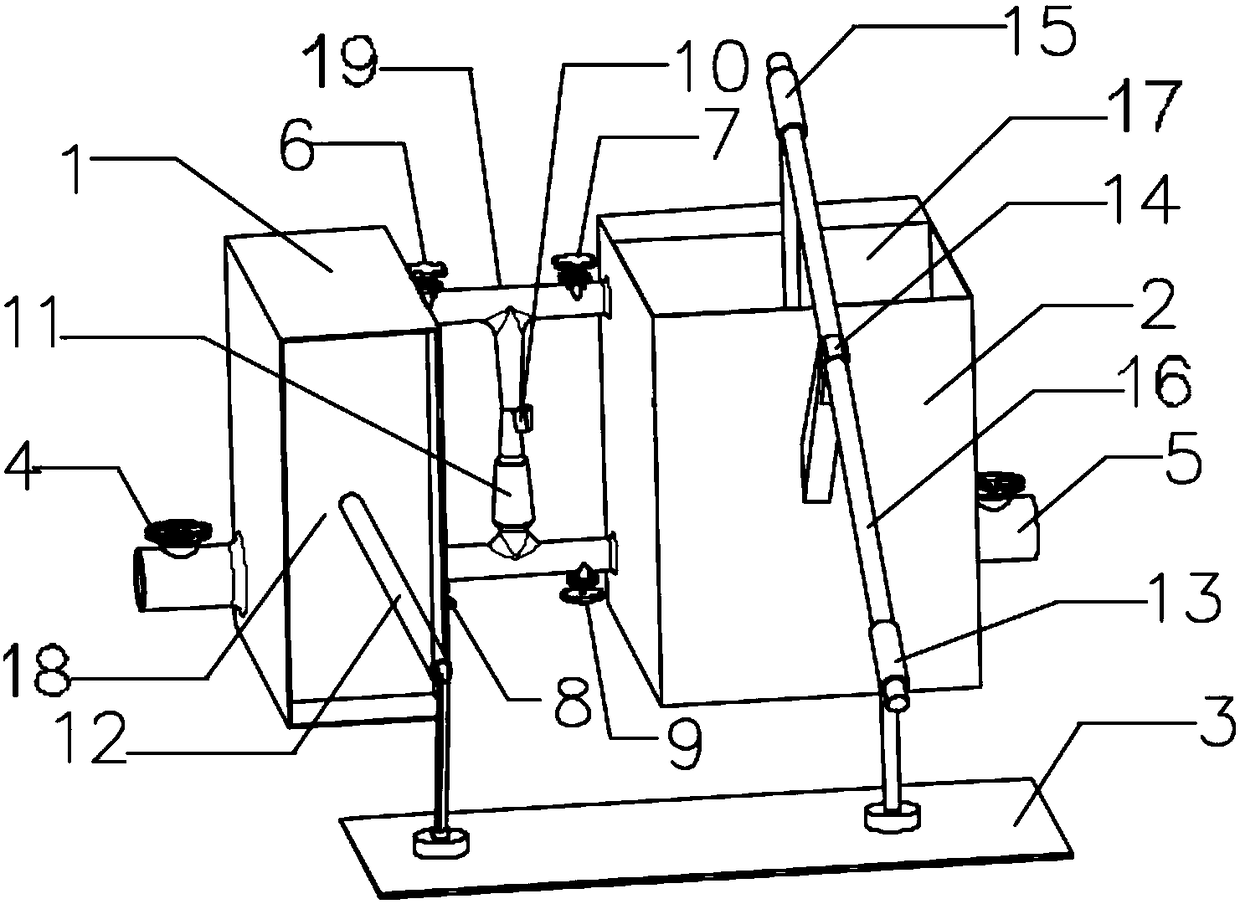

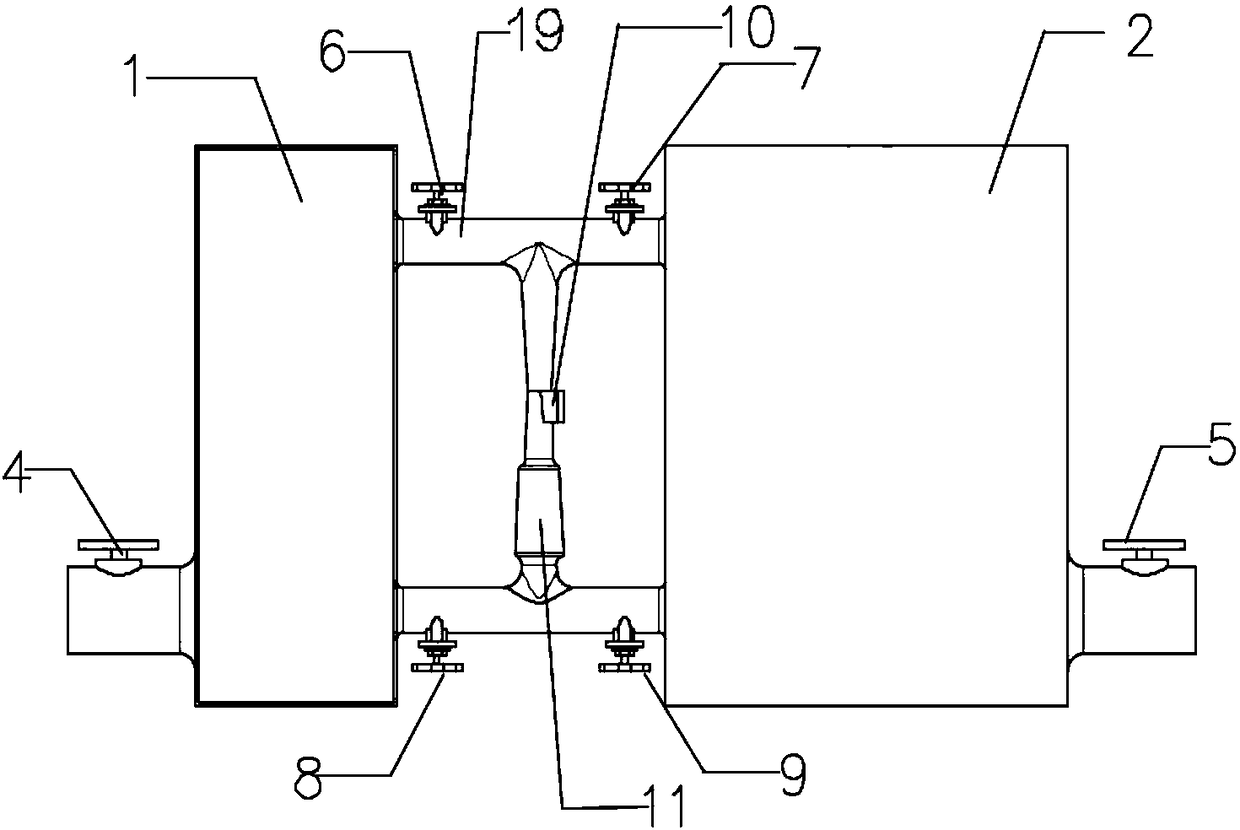

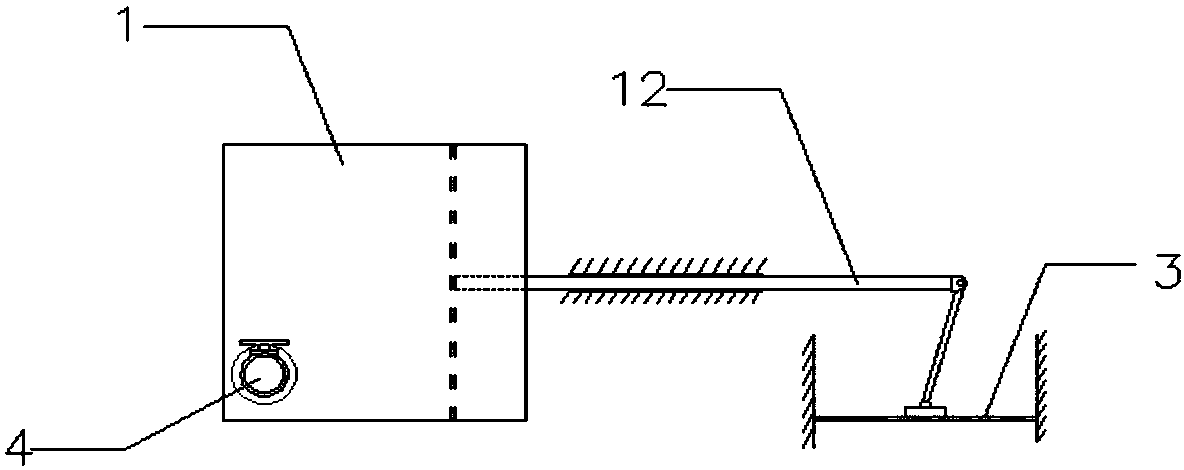

[0032] The invention provides an oscillating wave energy power generation system, comprising: a wave absorbing device, an energy conversion device and an energy output device. In the energy conversion device, when the wave crest comes, the piston on the left side moves in the horizontal direction, and the piston on the right side moves in the vertical direction, so that the two pistons respectively compress and suck the liquid in the wave-energy sealed tank to form a stronger The kinetic energy of the liquid improves the conversion efficiency of wave energy; the water delivery pipeline adopts the H-shaped pipeline design so that the reciprocating fluid in the liquid tank passes through the turbine in the energy output device from the same direction, which improves the power generation efficiency; The filter under the flat machine makes the sewage be continuously purified and discharged after a certain period. Conversely, the same is true when the trough comes.

[0033] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com