Timber cutting and peeling device

A wood and shock absorbing device technology, which is applied to wood processing equipment, bark, manufacturing tools, etc., can solve the problems of staff's feet numbness, floor cracking, and increase the operating burden of users, so as to avoid paralysis , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

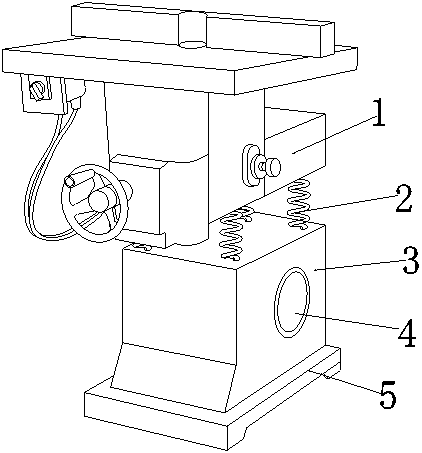

[0029] see Figure 1-Figure 7 , the present invention provides wood cutting and peeling device, its structure comprises workbench 1, damping spring 2, damping device 3, shell 4, base 5, described shell 4 is arranged on base 5 and is mechanically welded with base 5, The housing 4 is provided with a damping device 3, and the damping springs 2 are provided with four and are respectively mounted on the four corners of the top panel of the housing 4, and the damping springs 2 run through the top panel of the housing 4 and the The damping device 3 is mechanically connected, and the other end of the damping spring 2 is fixedly connected to the bottom of the workbench 1;

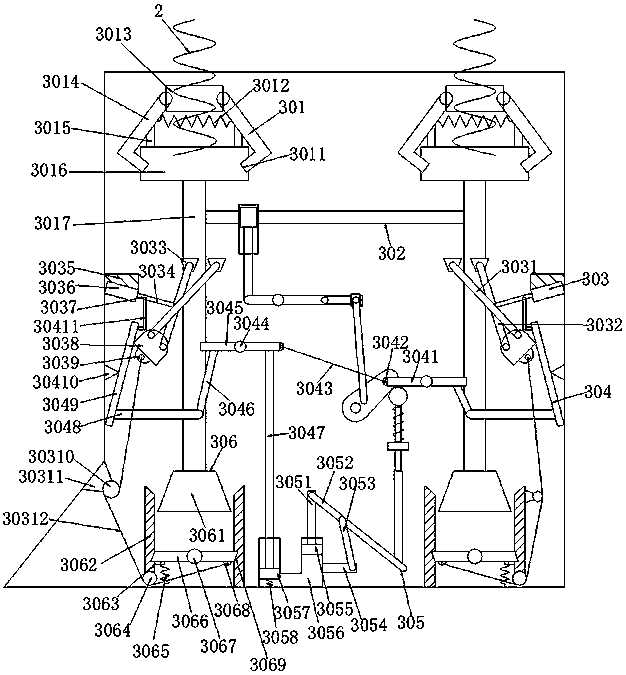

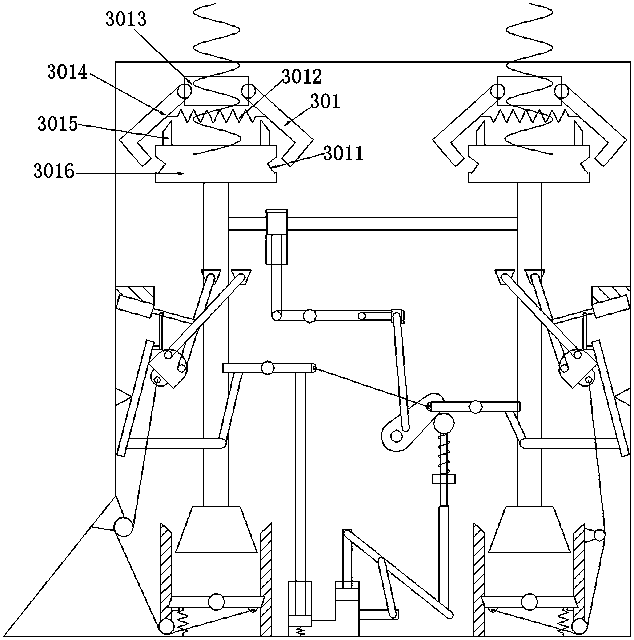

[0030] The shock absorbing device 3 is composed of a buffer device 301, a mechanical driving device 302, a suction cup control device 303, a control device driving mechanism 304, a differential pressure driving mechanism 305, and a suction cup fixing device 306;

[0031] The buffer device 301 is mechanically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com