Printing ink cartridge

A technology of ink cartridges and ink chambers, which is applied in the field of electronic products, and can solve problems such as the inability to solve the problem of residual ink, the reduction of ink capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

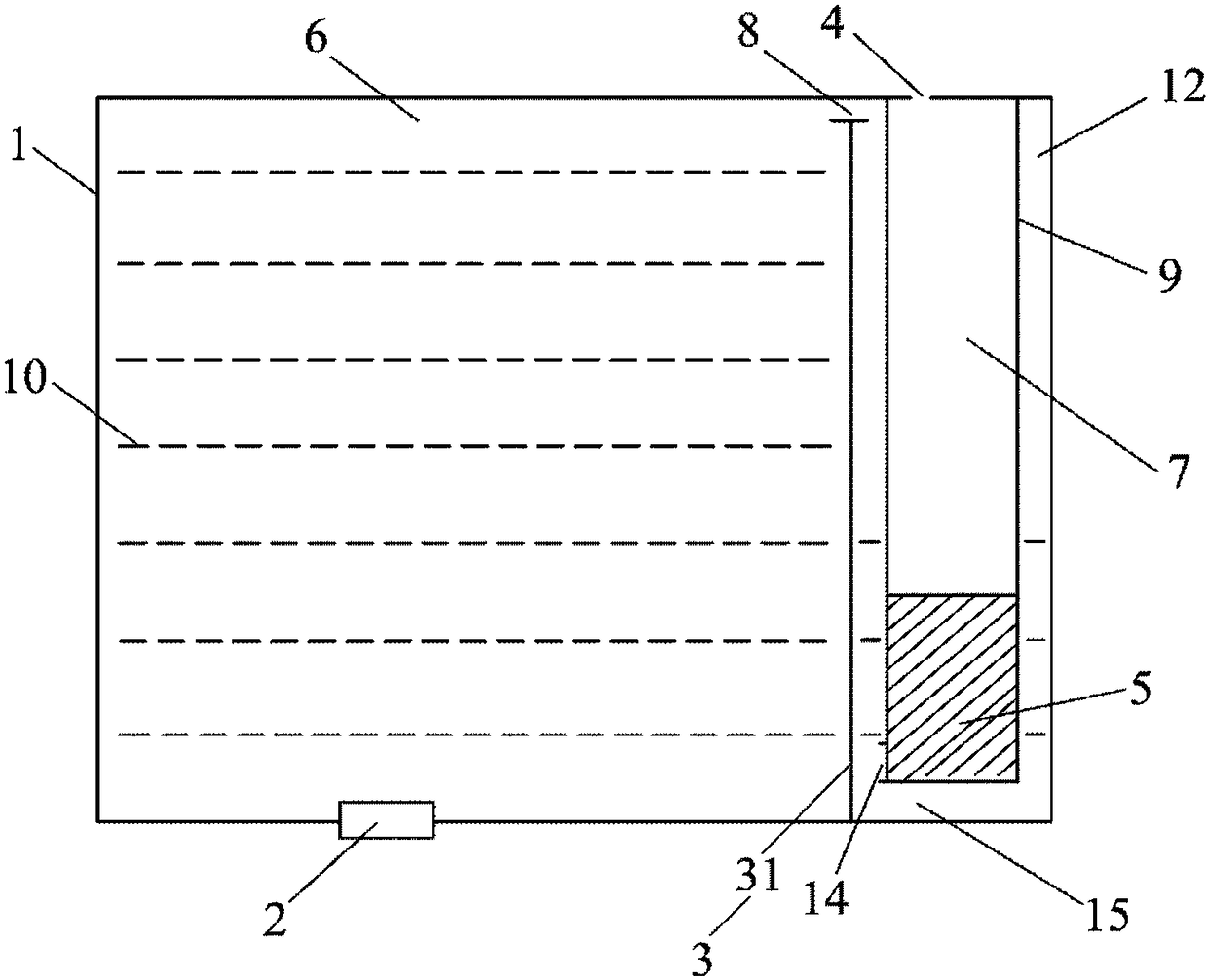

[0086] see Figure 1 to Figure 1B As shown, in the first specific embodiment of the present invention, the printing ink cartridge of the present invention includes a housing 1, an ink outlet device 2, a first partition wall 3, a first air guide channel 4, a gas-liquid exchange device 5, and a buffer chamber 7. The first communication channel 8 and the buffer chamber 9, the first partition wall 3 is set in the inner cavity of the housing 1 so as to divide the inner cavity of the housing 1 into the ink chamber 6 and the communication chamber 12, and the ink outlet device 2 is arranged in the The bottom of the ink chamber 6, the first communication channel 8 is arranged between the first partition wall 3 and the top of the housing 1 so as to communicate with the ink chamber 6 and the communication chamber 12, the buffer chamber 9 is arranged in the communication chamber 12, and the buffer chamber 9 An opening 14 is provided, and the opening 14 communicates with the first communic...

Embodiment 2

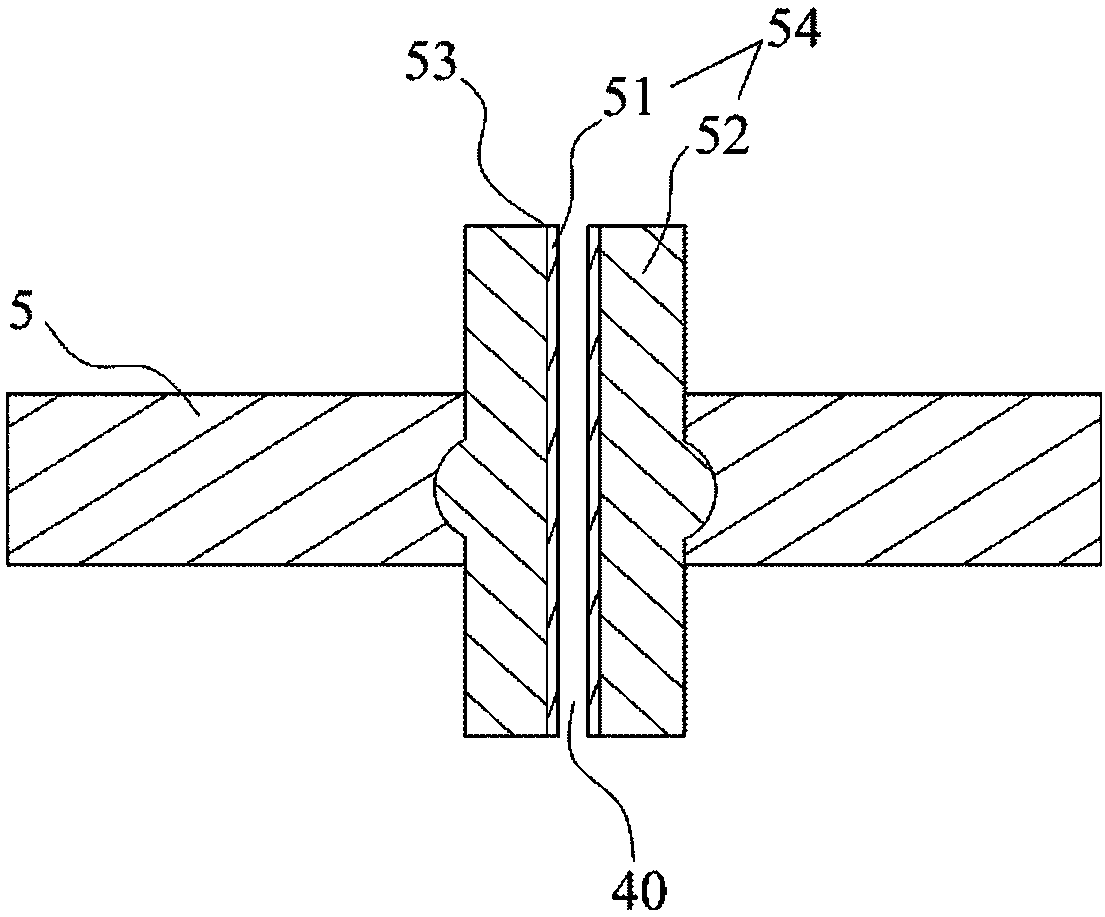

[0092] see figure 2 and Figure 2A As shown, the structure and working principle of the second embodiment of the present invention are similar to those of embodiment 1, the difference is that: the first communication channel 8 is arranged in the upper part of the vertical partition wall 31; the opening 14 is arranged at the bottom of the buffer chamber 9 and There is a gap 15 between the bottom of the buffer chamber 9 and the bottom of the communication chamber 12; the side of the buffer chamber 9 away from the first partition wall 3 is a part of the side of the communication chamber 12 away from the first partition wall 3, that is, a shared side, the maximum distance between the outer wall of the buffer chamber 9 and the inner wall of the communication chamber 12 is 0.5 millimeters; the core body 54 of the gas-liquid exchange device 5 is a single piece, which is a nylon 6 cylinder with convex ribs, and directly on the nylon 6 A capillary channel 40 is established in the mid...

Embodiment 3

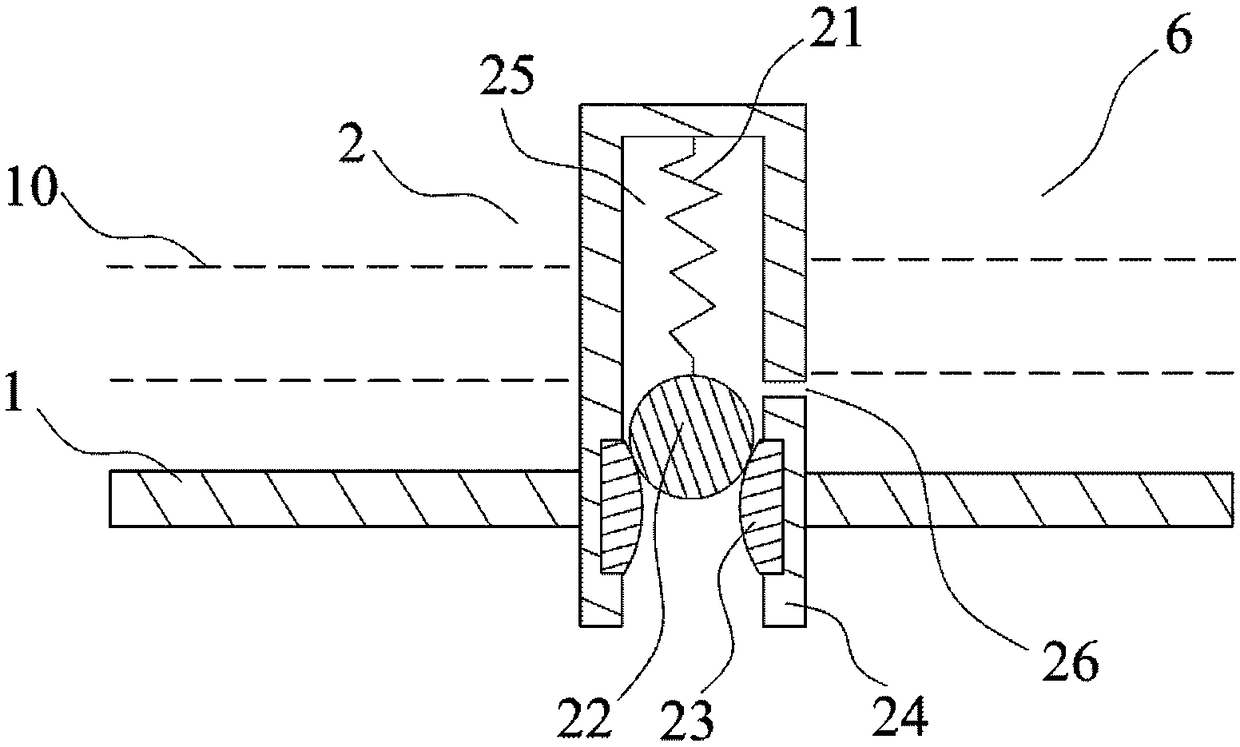

[0095] see Figure 3 to Figure 3B As shown, the third embodiment of the present invention is similar in structure and working principle to Embodiment 1, the difference is that: the first partition wall 3 includes a vertical partition wall 31 and a transverse partition wall 32, and the vertical partition wall 31 and the transverse partition wall 32 are connected to each other and are respectively connected to the inner wall of the housing 1; the two sides of the buffer chamber 9 are respectively a part of the two sides of the communicating chamber 12, that is, sharing both sides, the maximum distance between the outer wall of the buffer chamber 9 and the inner wall of the communicating chamber 12 is 0.1 mm; the first core 51 of the core 54 of the gas-liquid exchange device 5 is a ceramic cylinder with a diameter of 3 mm, and the second core 52 is integrally formed with other parts of the gas-liquid exchange device 5. For clarity, use The dotted line outlines part of the outline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com